OK i can grab a case of whip it locally tomorrow. after thinking about this all day can I tap the cans directly into my extractor? then distill the butane on the way back to the lp tank without tapping the cans directly into the lp tank first? My thinking is I dont want to put the mystery oil in my Lp tank, so if I can go from can directly to the extractor then recover to the lp tank and have distilled butane ready to go....also is there a need to keep the temps low during the distillation process? seems if your not concerned about the end product you could use higher temps for a faster process?

this info is on other threads, but never hurts....

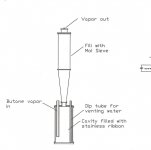

Assemble system as normal, have one of your used columns on the system...

We are going to VAC the entire system down to full VAC, including the fresh recovery tank.....

Then we are going to have a can tapper with an on / off vavle right at the tap needle and a hose attached to that.

Now attach the hose to the system with the tapper valve closed. Open the injection port to the system and draw a vac out of the hose.

Now your system should be a VAC all the way through... Make sure drop valve is closed (if your system is bottom feed).

Now tap can one (180* away from the seam, at least 1/4" up from the bottom). Open the valve on the can tapper and the vac should pull the contents in while the propellant in the cans also pushes it in.

We are running it through used material to help capture the mystery oil.

Turn on your recovery pump, valve off the can each time the system reaches just below 0"hg.

Swap cans, repeat.....