How do you guys like the flavor compared to top bho?

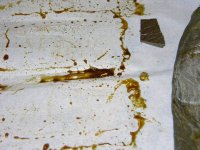

Not sure if you've ever tried anything from Green Dot Labs but they're considered to be one of the best processors in Colorado, their stuff flies off the shelf at 60/g and IMO all the rosin I've made so far is just as flavorful and good as anything I've ever tried from Green Dot. I think I posted the Rainbow Kush I pressed a couple pages back and that was THE most flavorful concentrate I've ever bought/made/or had.