G

Gr33nSanta

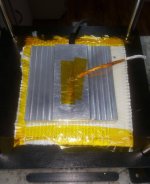

I have to say, I've been pressing for a while now, nothing commercial mind you, and the heat hasn't affected my press at all that I've noticed. 12 ton manual hydraulic.

same here, I kept thinking, what are they talking about!! lol mine is never on for more than an hour or 2.