Cool thread....

-

ICMag with help from Landrace Warden and The Vault is running a NEW contest in November! You can check it here. Prizes are seeds & forum premium access. Come join in!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

G

greenhornets

bump

Geoffrey Boycot

Member

OK. planning a system and i need some help with how the pressures in that system will work. smell is NOT an issue for this exercise AT ALL.

I will have 3 x 600 hps in PARALLEL over a 4x8ft area. Each 600 hps will be exhausted by a 6" $25 duct booster from home depot. (160cfm at no resistance). I'm not sure yet whether the inlet air will come from outside the chamber or inside. but either way the max distance from inlet to duct booster is 3ft.

each duct booster will vent into a larger main duct (8" - maybe even 12" if you recommend it). That larger duct will be running perpendicular to the 3 light-venting ducts. It will be approx 10ft long. It will be exhasuted by an 8" home depot duct booster (250? cfm with no resistance) into an attic.

Now my question is about the pressures and resistance in the main 8" duct. As i understand it the 3 inline duct boosters will be able to handle a 3ft duct run in order to vent the lights at over 100cfm each resulting in the 20-30F exhaust temps. This will increase the pressure in the 8" duct which is being vented at approx 150 cfm due to the longer 10ft duct run but benefitting from the wider diameter.

So i have 3x100CFM going into the central duct and 150-200cfm max leaving it....so the pressure will build up - will this put pressure on the 3xhps fans? making it harder for them to push air into the central duct and choking them down very badly? Would a second 8" fan in series with the first get the power back up towards 250 cfm?

If so what kind of central duct do i need (diameter/fan strength) to pull off exhausting 3x600w hps with 3x6" $25 duct boosters. An escape vale of some sort required perhaps?

Sorry but the shape of the room isnt really changable. and i like the idea of using low powered quiet cheap fans well engineered to produce the desiered result and this thread seems to suggest its possible if only using them to cool lights and not a grow area.

cheers all!

I will have 3 x 600 hps in PARALLEL over a 4x8ft area. Each 600 hps will be exhausted by a 6" $25 duct booster from home depot. (160cfm at no resistance). I'm not sure yet whether the inlet air will come from outside the chamber or inside. but either way the max distance from inlet to duct booster is 3ft.

each duct booster will vent into a larger main duct (8" - maybe even 12" if you recommend it). That larger duct will be running perpendicular to the 3 light-venting ducts. It will be approx 10ft long. It will be exhasuted by an 8" home depot duct booster (250? cfm with no resistance) into an attic.

Now my question is about the pressures and resistance in the main 8" duct. As i understand it the 3 inline duct boosters will be able to handle a 3ft duct run in order to vent the lights at over 100cfm each resulting in the 20-30F exhaust temps. This will increase the pressure in the 8" duct which is being vented at approx 150 cfm due to the longer 10ft duct run but benefitting from the wider diameter.

So i have 3x100CFM going into the central duct and 150-200cfm max leaving it....so the pressure will build up - will this put pressure on the 3xhps fans? making it harder for them to push air into the central duct and choking them down very badly? Would a second 8" fan in series with the first get the power back up towards 250 cfm?

If so what kind of central duct do i need (diameter/fan strength) to pull off exhausting 3x600w hps with 3x6" $25 duct boosters. An escape vale of some sort required perhaps?

Sorry but the shape of the room isnt really changable. and i like the idea of using low powered quiet cheap fans well engineered to produce the desiered result and this thread seems to suggest its possible if only using them to cool lights and not a grow area.

cheers all!

B

bottletoke

So after reading this whole thread i have a question.

You guys seem to think that 2 smaller fans, one each for scrubbing and one for cooltube is the way to go.

I was originally going to use a 6" inline fan with the brute force approach ie, scrubber/cooltube in one.

But i realized that because of 12/12, you are going to want to have your room/tent scrubbed constantly because of the smell and the fan would be running when its not really needed, and besides, running a 6inch inline fan all the time sounds like alot of noise.

Would two axial fans produce less noise than the 6inch elicent inline fan rated at 300 something cfm?

How would you guys approach a 3.5' x 3.5 tent with 600w cooltube?

I have to sleep in the same room and im looking for the quietest options.

thanks in advance

bottletoker..

You guys seem to think that 2 smaller fans, one each for scrubbing and one for cooltube is the way to go.

I was originally going to use a 6" inline fan with the brute force approach ie, scrubber/cooltube in one.

But i realized that because of 12/12, you are going to want to have your room/tent scrubbed constantly because of the smell and the fan would be running when its not really needed, and besides, running a 6inch inline fan all the time sounds like alot of noise.

Would two axial fans produce less noise than the 6inch elicent inline fan rated at 300 something cfm?

How would you guys approach a 3.5' x 3.5 tent with 600w cooltube?

I have to sleep in the same room and im looking for the quietest options.

thanks in advance

bottletoker..

Great thread!

Unfortunately, I am a mathematical idiot, so I need some help calculating my ventilation needs.

I'm planning a micro cab (SIMPLE GROW BOX version) with no filter/scrubber. I would prefer a single PC fan for exhaust at the top of the cab and two passive intake holes at the bottom.

Inside cab dimensions (approximately):

Height: 26'' (66cm)

Lenght: 18'' (46cm)

Width: 14'' (35cm)

Total: 3,8 cubic feet (0,11 cubic meters)

Lights: 2*36W PLL (2*2900 lumens; 80,5 lumen/watt)

How powerful should the exhaust fan be?

Any help will be much appreciated!

Unfortunately, I am a mathematical idiot, so I need some help calculating my ventilation needs.

I'm planning a micro cab (SIMPLE GROW BOX version) with no filter/scrubber. I would prefer a single PC fan for exhaust at the top of the cab and two passive intake holes at the bottom.

Inside cab dimensions (approximately):

Height: 26'' (66cm)

Lenght: 18'' (46cm)

Width: 14'' (35cm)

Total: 3,8 cubic feet (0,11 cubic meters)

Lights: 2*36W PLL (2*2900 lumens; 80,5 lumen/watt)

How powerful should the exhaust fan be?

Any help will be much appreciated!

SickBoyZap

Member

Does anybody know about either repairing or diagnosing an 'in-line' fan. My 12" started to make some noise about a year ago after being used for about 3 years. It worked fine for the last year and just today it just starts making a struggling electric hum sound when you try to turn it on. I can't aford a new one right now. Any suggestions?

GB,OK. planning a system and i need some help with how the pressures in that system will work. smell is NOT an issue for this exercise AT ALL.

I will have 3 x 600 hps in PARALLEL over a 4x8ft area. Each 600 hps will be exhausted by a 6" $25 duct booster from home depot. (160cfm at no resistance). I'm not sure yet whether the inlet air will come from outside the chamber or inside. but either way the max distance from inlet to duct booster is 3ft.

each duct booster will vent into a larger main duct (8" - maybe even 12" if you recommend it). That larger duct will be running perpendicular to the 3 light-venting ducts. It will be approx 10ft long. It will be exhasuted by an 8" home depot duct booster (250? cfm with no resistance) into an attic.

Now my question is about the pressures and resistance in the main 8" duct. As i understand it the 3 inline duct boosters will be able to handle a 3ft duct run in order to vent the lights at over 100cfm each resulting in the 20-30F exhaust temps. This will increase the pressure in the 8" duct which is being vented at approx 150 cfm due to the longer 10ft duct run but benefitting from the wider diameter.

So i have 3x100CFM going into the central duct and 150-200cfm max leaving it....so the pressure will build up - will this put pressure on the 3xhps fans? making it harder for them to push air into the central duct and choking them down very badly? Would a second 8" fan in series with the first get the power back up towards 250 cfm?

If so what kind of central duct do i need (diameter/fan strength) to pull off exhausting 3x600w hps with 3x6" $25 duct boosters. An escape vale of some sort required perhaps?

Sorry but the shape of the room isnt really changable. and i like the idea of using low powered quiet cheap fans well engineered to produce the desiered result and this thread seems to suggest its possible if only using them to cool lights and not a grow area.

cheers all!

Duct boosters are not very powerful at all. Any resistance on them pulls on them hard. From what you are saying, you would have 3 $30 fans and another $40.

What I would suggest you do is tie the lights end-to-end with the 6" flex duct and take it all the way to the attic. What I do is take the 6" to a Stanley/Lasko DIY fan. But for the money you would spend on those boosters, you could have a real nice S&P inline that has lots of power.

It is never really a good idea to T into other lines without doing it considering proper sizing. Although, I do think your proposed set-up would work OK. I would be very suspect of the boosters doing what you want though...having a good deal of experience with them.

Add scrubber, and they are a no go.

So after reading this whole thread i have a question.

You guys seem to think that 2 smaller fans, one each for scrubbing and one for cooltube is the way to go.

I was originally going to use a 6" inline fan with the brute force approach ie, scrubber/cooltube in one.

But i realized that because of 12/12, you are going to want to have your room/tent scrubbed constantly because of the smell and the fan would be running when its not really needed, and besides, running a 6inch inline fan all the time sounds like alot of noise.

Would two axial fans produce less noise than the 6inch elicent inline fan rated at 300 something cfm?

How would you guys approach a 3.5' x 3.5 tent with 600w cooltube?

I have to sleep in the same room and im looking for the quietest options.

thanks in advance

bottletoker..

If it were me, I would run two separate lines and fans.

If the noise becomes an issue, you could use speed controllers.

DOWNLOW

Active member

Well those charts I guess were usefull for lot of ppl here but not me

My cab is 36"L x 34"H x 19" deep I'm running 400 watter thru a bake

around cool tube thru the top with 4" inline fan into a scrubber. My

intakes are two 3"x3" intakes located in the garden. My tempts so

far are runnings in the ninties during my test runs this my flowering

area which is wat I've just described. heres a look at it. Should

I enlargen my intakes, or go bare bulb.

My cab is 36"L x 34"H x 19" deep I'm running 400 watter thru a bake

around cool tube thru the top with 4" inline fan into a scrubber. My

intakes are two 3"x3" intakes located in the garden. My tempts so

far are runnings in the ninties during my test runs this my flowering

area which is wat I've just described. heres a look at it. Should

I enlargen my intakes, or go bare bulb.

Attachments

gdbud

Member

4" inline fan into a scrubber. My

intakes are two 3"x3" intakes

A 4" hole has an area of 12.5sq.in.

A 3" hole has an area of 7". 2 3" hole have an area of 14sq.in.

The min. ratio between intake and exhaust is 1.20:1 most people use 2:1 and you are currently at 1.125:1. You need to increase the intakes if you add another 3" hole which will give you an area of 12.2sq.in.and a ratio of 1.7:1.

What I'm saying is you need to add another 3" hole and you should be fine.

Numboard

Member

Id like to introduce yall to "delta" brand axial fans.

http://www.sidewindercomputers.com/delhigper.html

I'm a pc modder on the side and no other "computer" fans come even close to delta. (exept that one sanace)

Heres a quick video I took a while ago of a delta blower I came across at a local electronics store. Uses 3 amps at 12 volts. http://smg.photobucket.com/albums/v603/maxspam/?action=view¤t=MVI_2731.flv

http://www.delta.com.tw/product/cp/dcfans/download/pdf/BCB/BCB97x94x32mm.pdf The cfm is crummy but the static pressure is just stupid

/fan sperging

http://www.sidewindercomputers.com/delhigper.html

I'm a pc modder on the side and no other "computer" fans come even close to delta. (exept that one sanace)

Heres a quick video I took a while ago of a delta blower I came across at a local electronics store. Uses 3 amps at 12 volts. http://smg.photobucket.com/albums/v603/maxspam/?action=view¤t=MVI_2731.flv

http://www.delta.com.tw/product/cp/dcfans/download/pdf/BCB/BCB97x94x32mm.pdf The cfm is crummy but the static pressure is just stupid

/fan sperging

Tactical Farmer

Member

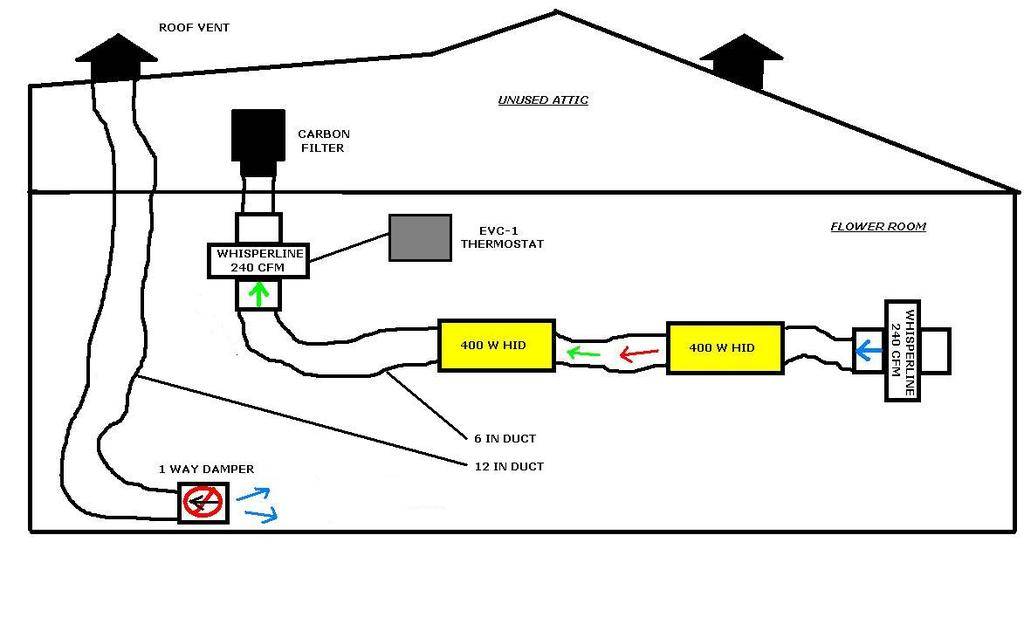

Ive been going through push vs. pull threads & going back & forth with different designs.

ALOT of variations - hope this is the best way to cool - get fresh air & oder control in the summer ?

Please help me out - only got a few day window for construction.

Have to drill 2 6in holes through my new drywall - insulation & attic floor so if its a wack plan let me know so I dont butcher the nice new room.

ALOT of variations - hope this is the best way to cool - get fresh air & oder control in the summer ?

Please help me out - only got a few day window for construction.

Have to drill 2 6in holes through my new drywall - insulation & attic floor so if its a wack plan let me know so I dont butcher the nice new room.

gdbud

Member

T. Farmer, With the static pressure from on your two HID lights and your carbon filter the CFM from your fan could be cut in half to around 125 CFM. Then with your 250 CFM intake fan you would be pressurizing your grow room BAD IDEA!

Instead you should use passive intakes and your intakes should be a min. of 20% larger of your exhaust. Most people use intake 2X of their exhaust.

Instead you should use passive intakes and your intakes should be a min. of 20% larger of your exhaust. Most people use intake 2X of their exhaust.

Numboard

Member

Seconded.T. Farmer, With the static pressure from on your two HID lights and your carbon filter the CFM from your fan could be cut in half to around 125 CFM. Then with your 250 CFM intake fan you would be pressurizing your grow room BAD IDEA!

Instead you should use passive intakes and your intakes should be a min. of 20% larger of your exhaust. Most people use intake 2X of their exhaust.

Tactical Farmer

Member

Damn - I see what you mean, daahhhh...

This seems like it would work better without having to buy another fan ?

The room is pretty sealed - so with the pressure concept this (passive intake) should cause a vacuum in the room causing fresh air to be forced down the 12 in duct at a good rate ?

Looks like I will need a 12 in damper to keep dirty air from sneaking out the intake if the exhaust is off.

This seems like it would work better without having to buy another fan ?

The room is pretty sealed - so with the pressure concept this (passive intake) should cause a vacuum in the room causing fresh air to be forced down the 12 in duct at a good rate ?

Looks like I will need a 12 in damper to keep dirty air from sneaking out the intake if the exhaust is off.

Numboard

Member

Well the air has to some from somewhere right? If the room is sealed good it has no choice but to come through the 12". Damper is a good idea. might add some restriction though

Also I would PULL through the scrubber rather than push. Put it in a corner standing up with duct running to the hoods. scrub>fan>hood>hood>fan>vent

Also I would PULL through the scrubber rather than push. Put it in a corner standing up with duct running to the hoods. scrub>fan>hood>hood>fan>vent