-

ICMag with help from Landrace Warden and The Vault is running a NEW contest in November! You can check it here. Prizes are seeds & forum premium access. Come join in!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OvergrowingKiwi

Active member

Big thanks for this thread  lots of great info here...it helped me build my room

lots of great info here...it helped me build my room

G

guest 77721

KolorBlind

Member

Thanks RG

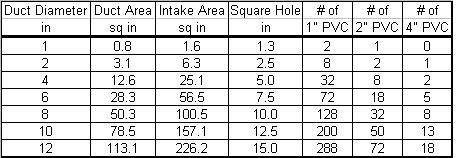

I saw the chart, in fact I have looked over the first page of this thread MANY times, and when you re-posted that chart for me was the first time I realized it was saying use TWO 4" PVC for a 4" exhaust. Dont know why I was thinking 4. I have all my 4" elbows painted now, and will be working on installing them soon. Thanks again for the thread man, glad to see ya back

KB

I saw the chart, in fact I have looked over the first page of this thread MANY times, and when you re-posted that chart for me was the first time I realized it was saying use TWO 4" PVC for a 4" exhaust. Dont know why I was thinking 4. I have all my 4" elbows painted now, and will be working on installing them soon. Thanks again for the thread man, glad to see ya back

KB

sub

Member

I ordered 3 Ultra Performance 120mm cpu fans for my 2' x 1.5' x 3' box. Still waiting for them, but they are 33.6dBA - and now I'm starting to get nervous about how loud 3 of these would be.. I'm tempted to get a whisperlite which could act as the exhaust fan (with carbon scrubber) but I don't really know much about it and have a feeling it'd be overkill for such a small box.

The cpu fans were a sort of impulse buy, but they were recommended by another grower (I forget where) - hopefully they work out ok. They have good specs, though:

Fan Size: 120 x 120 x 25 mm

Bearing Type: Dual Ball

RPM: 2100 RPM

Air Flow: 79.3 CFM

Noise Level: 33.6 dBA

Static Pressure: 2.98 mm/H2O

Voltage: 12 V

Power Consumption: 3.12 W

Figured they would be good for exhaust fans with carbon scrubbers, they have good static pressure (I think it's good anyway)

Maybe those 3 will be fine, even if I have to dim them a tiny bit. I figure use 2 as exhaust, either pulling through one big scrubber or 2 smaller ones, then use the other to pull air from the bottom to top. Or something along those lines.

Anyway... whisperlite.. overkill for 2' x 1.5' x 3'? Any thoughts on those fans? They should be here Tuesday either way so I can see/hear for myself (crossing my fingers!)

The cpu fans were a sort of impulse buy, but they were recommended by another grower (I forget where) - hopefully they work out ok. They have good specs, though:

Fan Size: 120 x 120 x 25 mm

Bearing Type: Dual Ball

RPM: 2100 RPM

Air Flow: 79.3 CFM

Noise Level: 33.6 dBA

Static Pressure: 2.98 mm/H2O

Voltage: 12 V

Power Consumption: 3.12 W

Figured they would be good for exhaust fans with carbon scrubbers, they have good static pressure (I think it's good anyway)

Maybe those 3 will be fine, even if I have to dim them a tiny bit. I figure use 2 as exhaust, either pulling through one big scrubber or 2 smaller ones, then use the other to pull air from the bottom to top. Or something along those lines.

Anyway... whisperlite.. overkill for 2' x 1.5' x 3'? Any thoughts on those fans? They should be here Tuesday either way so I can see/hear for myself (crossing my fingers!)

Hey Red, GREAT WORK!

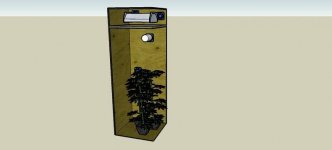

I am going for a design like in your 150HPS cab. I would like to copy the exact design actually. I have a few questions.

1. Can you take a few pics of the rear of the cab so everyone can see what it looks like. I would like to see how the light looks the way you have it wired up in rear of the cab.

2. Where do you vent the warm air from the light chamber? Out the top, through the furnace filters? Tell me I will be alright venting right into my room. Which is a finished basement. I had to buy a dehumidifier once due to flooding down here. Cost 250. Things half the size of a mini fridge. Think I will be alright running that if the RH gets to high in my room? I just don't want mold issues that I always here about, ya know? Or is venting into my room a bad idea? Its really the only choice I have.

3. Where is the best place in your opinion to find a plate of glass to seal the grow/light chambers?

Thanks Red, and everyone. I enjoyed reading this whole thread and coming to the realization that bigger isn't always better.

I am going for a design like in your 150HPS cab. I would like to copy the exact design actually. I have a few questions.

1. Can you take a few pics of the rear of the cab so everyone can see what it looks like. I would like to see how the light looks the way you have it wired up in rear of the cab.

2. Where do you vent the warm air from the light chamber? Out the top, through the furnace filters? Tell me I will be alright venting right into my room. Which is a finished basement. I had to buy a dehumidifier once due to flooding down here. Cost 250. Things half the size of a mini fridge. Think I will be alright running that if the RH gets to high in my room? I just don't want mold issues that I always here about, ya know? Or is venting into my room a bad idea? Its really the only choice I have.

3. Where is the best place in your opinion to find a plate of glass to seal the grow/light chambers?

Thanks Red, and everyone. I enjoyed reading this whole thread and coming to the realization that bigger isn't always better.

Last edited:

BeaverHuntr

Member

I am running a room that is 4' x 5' x 8' high venting using the 6'' can fan and filter (400 CFM) exhausting into the attic. I also took the AC duct from the bedroom and ran into the closet and sealed it. Since the AC is bringing in fresh cool air will I still need a intake hole or not? Thanks

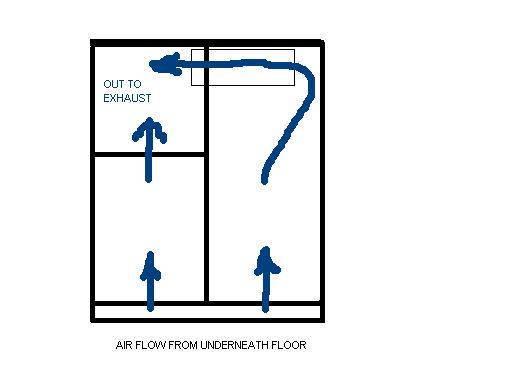

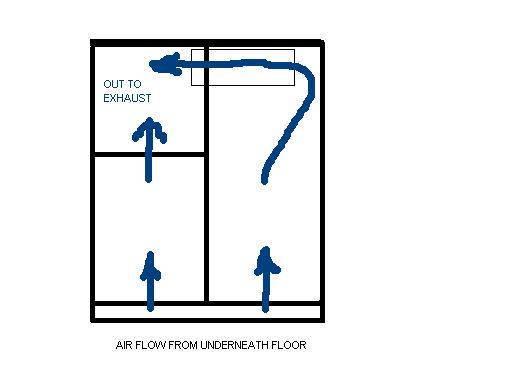

Hello redgreenry, I have a passive-intake question. I've got an NGB cab, a single exhaust and two types of passive-intake, internal and external.

The upper left chamber is utility. The exhaust fan is 4". There's a 4" hole coming from veg (lower left) and flower (right) to utility. These are the 2 internal intakes. BTW, the object in flower is a cool tube.

I have to cut external intakes in the (cab) floor of veg and flower. Should I cut a single 4" hole in each floor or two 4" holes in each floor?

I'm familiar with (A=Pi x R sq.) I'm just not sure if the external to internal intake ratio is 2:1 or 1:1. Thanks.

The upper left chamber is utility. The exhaust fan is 4". There's a 4" hole coming from veg (lower left) and flower (right) to utility. These are the 2 internal intakes. BTW, the object in flower is a cool tube.

I have to cut external intakes in the (cab) floor of veg and flower. Should I cut a single 4" hole in each floor or two 4" holes in each floor?

I'm familiar with (A=Pi x R sq.) I'm just not sure if the external to internal intake ratio is 2:1 or 1:1. Thanks.

Last edited:

G

guest 77721

Hi CFLtime

this is the original build thread for the 150 HPS cab there's lot's of pics here.

https://www.icmag.com/ic/showthread.php?t=51189

It originally had two 65CFM fans in the light chamber, an external scrubber and a muffler box. I made some changes and run only one fan in the light chamber and use an internal scrubber now. I moved the box from a larger upstairs closet to a small utilily closet and didn't have the room for all that ducting so my updated design is more compact.

https://www.icmag.com/ic/showpost.php?p=2199088&postcount=31

I've been fooling around with combinations of lights and would recommend using 4x 26 W for starting seedlings, 4 x 42w CFL's for vegging and a 150HPS plus 2x 42W CFL for flowering.

this is the original build thread for the 150 HPS cab there's lot's of pics here.

https://www.icmag.com/ic/showthread.php?t=51189

It originally had two 65CFM fans in the light chamber, an external scrubber and a muffler box. I made some changes and run only one fan in the light chamber and use an internal scrubber now. I moved the box from a larger upstairs closet to a small utilily closet and didn't have the room for all that ducting so my updated design is more compact.

https://www.icmag.com/ic/showpost.php?p=2199088&postcount=31

I've been fooling around with combinations of lights and would recommend using 4x 26 W for starting seedlings, 4 x 42w CFL's for vegging and a 150HPS plus 2x 42W CFL for flowering.

G

guest 77721

I am running a room that is 4' x 5' x 8' high venting using the 6'' can fan and filter (400 CFM) exhausting into the attic. I also took the AC duct from the bedroom and ran into the closet and sealed it. Since the AC is bringing in fresh cool air will I still need a intake hole or not? Thanks

Hey BeaverHuntr

I wouldn't think you'd need an intake hole unless your temps are too high. If you are having problems it's likely the filter blocking up too much of the air flow.

G

guest 77721

Hey DiscoBiscuit,

I've got to check out your growlog. I remember you from the R2D2 club a while back.

Those NGB cabs are difficult to get the airflow balanced in all the chambers. Every chamber causes a pressure loss and a corresponding drop in airflow. Sadly you have to double the intake size for each subsequent chamber to maintain flow. Also if you have a mixture of different sized chambers and ducting, the airflow won't be balanced.

What you have is a reverse muffler. A muffler has multiple chambers designed to produce a backpressure and restrict flow. The internal piping uses the same size duct as the inlet and exhaust. There may be two or three internal chambers in a muffler.

I've got to check out your growlog. I remember you from the R2D2 club a while back.

Those NGB cabs are difficult to get the airflow balanced in all the chambers. Every chamber causes a pressure loss and a corresponding drop in airflow. Sadly you have to double the intake size for each subsequent chamber to maintain flow. Also if you have a mixture of different sized chambers and ducting, the airflow won't be balanced.

What you have is a reverse muffler. A muffler has multiple chambers designed to produce a backpressure and restrict flow. The internal piping uses the same size duct as the inlet and exhaust. There may be two or three internal chambers in a muffler.

Hello redgreenry, I have a passive-intake question. I've got an NGB cab, a single exhaust and two types of passive-intake, internal and external.

The upper left chamber is utility. The exhaust fan is 4". There's a 4" hole coming from veg (lower left) and flower (right) to utility. These are the 2 internal intakes. BTW, the object in flower is a cool tube.

I have to cut external intakes in the (cab) floor of veg and flower. Should I cut a single 4" hole in each floor or two 4" holes in each floor?

I'm familiar with (A=Pi x R sq.) I'm just not sure if the external to internal intake ratio is 2:1 or 1:1. Thanks.

first of thanks fore al the info in this thread guys and girls!

i planing on geting a grow tent xxl 4x8x6,5ft whit 3x600w hps air cooled hoods using 2 fans one fore the hoods and the other one fore the scrubber.

the problem where i am stuck is how can i cool the hoods best when the connections only are 5" and the fan is 8" ?

can i just put a reducer straight after the fan and then run 5" ducting?

live in a really warm climate so i dont want any heat from the lamps in the grow rom.

i planing on geting a grow tent xxl 4x8x6,5ft whit 3x600w hps air cooled hoods using 2 fans one fore the hoods and the other one fore the scrubber.

the problem where i am stuck is how can i cool the hoods best when the connections only are 5" and the fan is 8" ?

can i just put a reducer straight after the fan and then run 5" ducting?

live in a really warm climate so i dont want any heat from the lamps in the grow rom.

Hey DiscoBiscuit,

I've got to check out your growlog. I remember you from the R2D2 club a while back.

Those NGB cabs are difficult to get the airflow balanced in all the chambers. Every chamber causes a pressure loss and a corresponding drop in airflow. Sadly you have to double the intake size for each subsequent chamber to maintain flow. Also if you have a mixture of different sized chambers and ducting, the airflow won't be balanced.

What you have is a reverse muffler. A muffler has multiple chambers designed to produce a backpressure and restrict flow. The internal piping uses the same size duct as the inlet and exhaust. There may be two or three internal chambers in a muffler.

I kind of miss ol' R2, hope he's still around. My grow log is a bit lonely these days. Heat and humidity has made cloning with a new puck-dome tricky. I managed to get 2 of 10 to make it but they're struggling.

Thanks for the detailed answer, rg. Especially the part about doubling 2x per subsequent chamber. I hope to increase veg flow w/o depriving flower. There's a slight motor whine when the doors close. I prolly 2x the veg floor and see what happens.

G

guest 77721

Hi nbody

It doesn't sound like you've bought equipment yet. Fans come in various duct sizes. If you have two fans of the same model line, reducing an 8 down to a 5 will give you the performance of the 5. You'd be better off to just buy a 5 in the first place and save some $$$.

It doesn't sound like you've bought equipment yet. Fans come in various duct sizes. If you have two fans of the same model line, reducing an 8 down to a 5 will give you the performance of the 5. You'd be better off to just buy a 5 in the first place and save some $$$.

first of thanks fore al the info in this thread guys and girls!

i planing on geting a grow tent xxl 4x8x6,5ft whit 3x600w hps air cooled hoods using 2 fans one fore the hoods and the other one fore the scrubber.

the problem where i am stuck is how can i cool the hoods best when the connections only are 5" and the fan is 8" ?

can i just put a reducer straight after the fan and then run 5" ducting?

live in a really warm climate so i dont want any heat from the lamps in the grow rom.

thanks fore your help redgreenry.

haven`t bought the fans yet but i think i will go whit the 8" fan and buy some bigger hoods instead.

what size would you recommend to cool 3x600w hps?

´

haven`t bought the fans yet but i think i will go whit the 8" fan and buy some bigger hoods instead.

what size would you recommend to cool 3x600w hps?

´

Hi nbody

It doesn't sound like you've bought equipment yet. Fans come in various duct sizes. If you have two fans of the same model line, reducing an 8 down to a 5 will give you the performance of the 5. You'd be better off to just buy a 5 in the first place and save some $$$.

G

guest 77721

Hey nbody

Each 600w needs 190 CFM to cool within 10*F of ambient. With a ventilated hood, the exhaust temps can run as high as 30*F

so each 600W needs 63CFM for a total of 189 CFM.

1-> 63CFM |

2-> 63CFM |->190 CFM Fan

3-> 63CFM |

Now if you're going to run them in a series the exhaust temps add up so at 63 CFM, the final exit temps will be 90*F above ambient which is too hot. Let's design for a 30*F exit temp or a 10*F rise per 600W light. That works out to 190 CFM from the chart.

1->2->3-> 190 CFM Fan

Each 600w needs 190 CFM to cool within 10*F of ambient. With a ventilated hood, the exhaust temps can run as high as 30*F

so each 600W needs 63CFM for a total of 189 CFM.

1-> 63CFM |

2-> 63CFM |->190 CFM Fan

3-> 63CFM |

Now if you're going to run them in a series the exhaust temps add up so at 63 CFM, the final exit temps will be 90*F above ambient which is too hot. Let's design for a 30*F exit temp or a 10*F rise per 600W light. That works out to 190 CFM from the chart.

1->2->3-> 190 CFM Fan

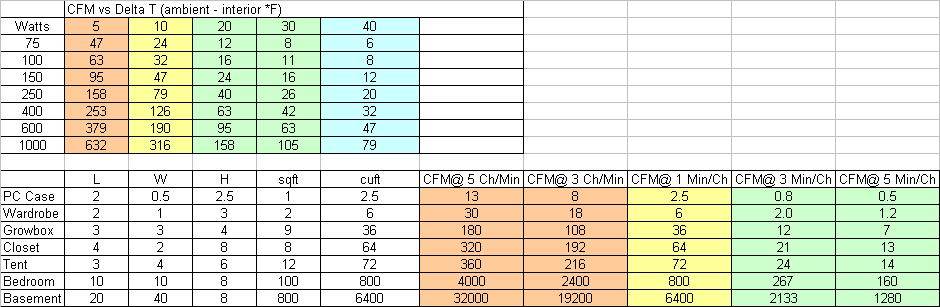

Hey guys,

Ventilation Chart

RECOMMENDED SPECIFICATIONS FOR GROWBOXES:

Simple Cabinet - airflow to maintain temperature within 10*F of ambient

Cool Tube or Ventilated Hood - exhaust air temp 20 - 30 *F. Hoods can be connected together to a common fan at 20 *F rise per hood, no more than 4 hoods for a total rise of 80 *F.

Grow Chamber Ventilation - 1 to 5 Minutes per Air Change. This is different for every type of light and setup. The more heat that is removed using a cool tube or ventilated heat means you can drop the grow chamber ventilation down further. The plants don't need very much air exchange and over 1 ACpM will cause unnecessary stress.

S

Smoking Now

Bookmarked for future reference!

G

guest 77721

Hey guys,

I just rewrote my section on Matching Fans and Filters. I was just helping out someone and realized that my first draft at this wasn't very clear.

RG

I just rewrote my section on Matching Fans and Filters. I was just helping out someone and realized that my first draft at this wasn't very clear.

RG

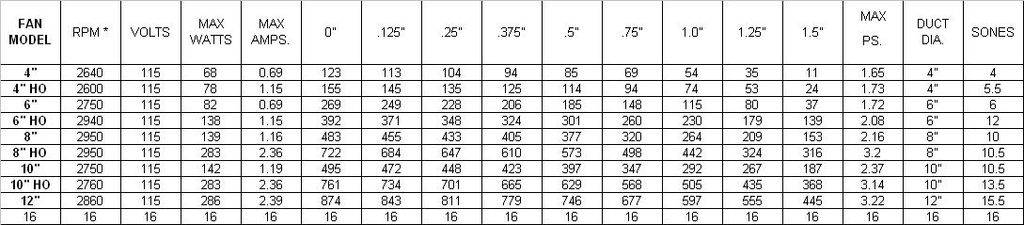

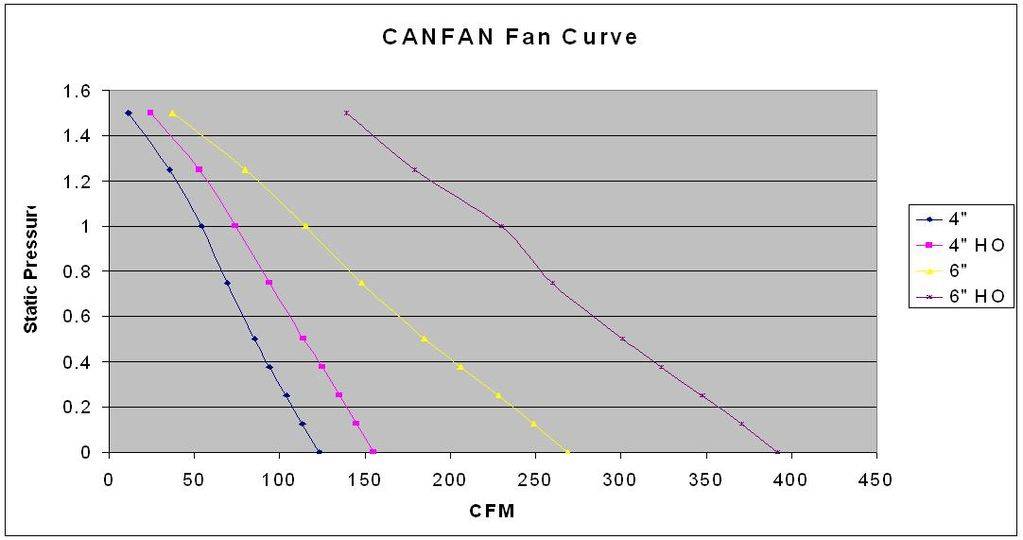

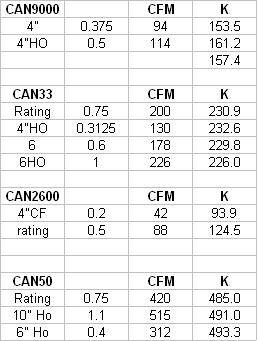

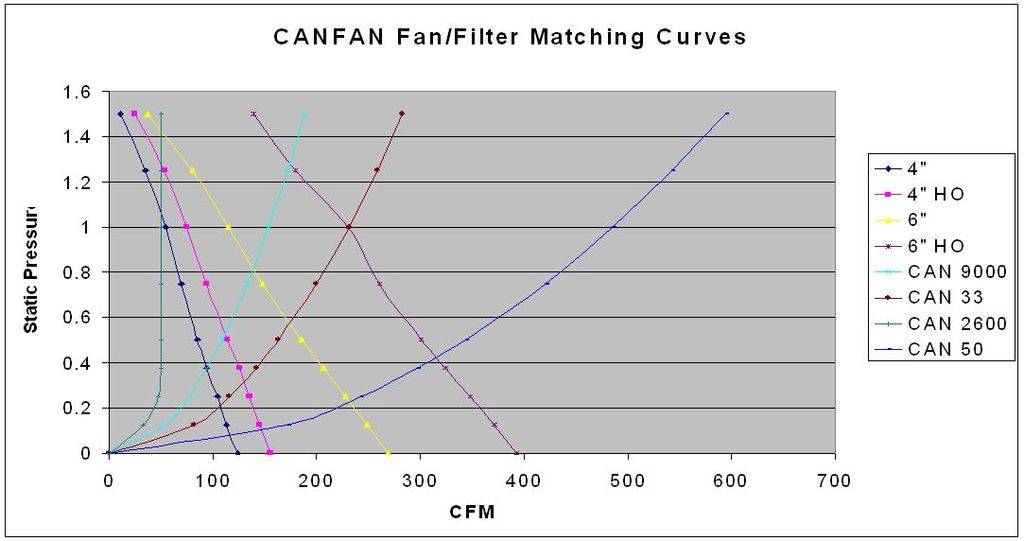

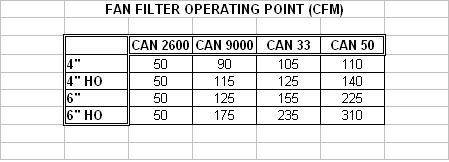

MATCHING FANS AND FILTERS

Matching a fan and a filter can be pretty tricky. You'll see lot's of lively discussions on this topic on this website. Most people rely on a salesman at a growshop or buy a matched fan and filter combo from a reputable manufacturer. Let me tell you that the curves can be easily created and you can verify easily if a fan and filter combination will be suitable for your grow setup.

Each Fan Manufacturer will provide a Flow vs Pressure curve. You'll need to get this to create the Fan Curve.

CANFAN Fan Specifications

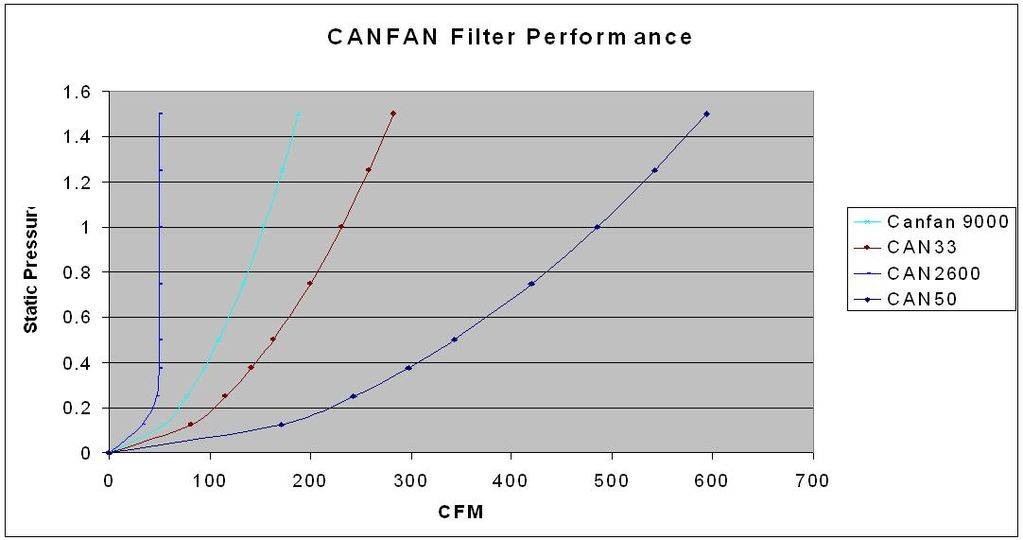

The other curve that you need is the Filter Performance Curve.

The filter performace curve follows the formula

CFM = K * SQRT(Pressure)

The Manufacturer will give you a CFM rating at a certain air pressure in the units inches of water. That's all you need to determine the K constant value for that filter.

K = CFM / SQRT(Pressure)

CANFAN Filter Performance Constants

CANFAN was nice to give us a few operating points for thier fan and filter combo's. That's all we need to get the K value for that filter.

Here's the CANFAN Filter Performance Curves

Now that we have our Fan Curve and our Filter Curves, let's put them on the same graph so we can see the operating points where the two curves cross.

Here's the operating points from where the fan curve crosses the filter curve.

Red,

I know you have helped out some people along the way. I have a question. I am going for the 4th option.

I am at a dilemma. I am trying to figure out the best way to vent this cab.

I have tried to do some math, but with carbon filters involved I dont really know what to do.

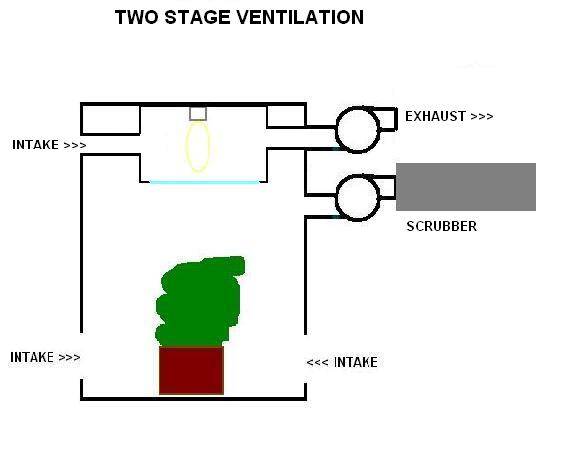

Here is one of my ideas (See Pic). My other idea is to just have passive holes at the bottom. (The program froze up and I lost my template)

The top portion is going to be basically just for the light and will have its own ventilation. It will be sealed off from the bottom portion. It will have it's own Intake and Exhaust. Exhaust will get carbon filter if smell is coming out of the top portion.

The bottom portion will have one 4" fan with carbon filter. The question is whether to have one 4" fan for intake or to have passive intake at the bottom of the cab. If the answer is passive intake, I was going to put 4x 2" PVC 90 degree elbows. I was going to put one at each corner but don't know how big they need to be to have the right kind of pressure. I know thats almost 1.5 times the size of intake. I didn't know if it would provide enough negative pressure with the carbon filter.

I know you have helped out some people along the way. I have a question. I am going for the 4th option.

4. Two Stage Cooling/Ventilation with cooltube and scrubber

LIGHTING CFM = 3.16*(Total Watts)/deltaT

where deltaT = 20 to 30 *F

VENTILATION = 1 - 5 Min/Ch (Minutes per Air Changes)

Intake Area = 2 x Exhaust Area for EACH section

Fans - Axial for Lighting maximum airflow, minimal pressure loss

Small blower, inline or axial for scrubber

Example: A 400 W HPS in a 3 x 3 x 4 cabinet with a ventilated hood needs 63 - 42 CFM of cooling for a 20-30*F temp rise in the exhaust temps with a 1-2 *F rise in the growbox. 5 Minutes between Air Changes requires only 7 CFM through the scrubber.

Pros:

unrestricted airflow through lighting allows fan to operate at maximum rated flow

low air flow rates allow for smallest scrubber

use of less expensive fans as design is more efficient

Lighting exhaust deltaT can be 20-30*F while maintaining low grow chamber temps

Much quieter as axial fans operate at 20-30 db compared to 60-70 for centrifugal fans

Cons:

more equipment

more intake and exhausts require more light proofing

ventilation design is more complex

I am at a dilemma. I am trying to figure out the best way to vent this cab.

I have tried to do some math, but with carbon filters involved I dont really know what to do.

Here is one of my ideas (See Pic). My other idea is to just have passive holes at the bottom. (The program froze up and I lost my template)

The top portion is going to be basically just for the light and will have its own ventilation. It will be sealed off from the bottom portion. It will have it's own Intake and Exhaust. Exhaust will get carbon filter if smell is coming out of the top portion.

The bottom portion will have one 4" fan with carbon filter. The question is whether to have one 4" fan for intake or to have passive intake at the bottom of the cab. If the answer is passive intake, I was going to put 4x 2" PVC 90 degree elbows. I was going to put one at each corner but don't know how big they need to be to have the right kind of pressure. I know thats almost 1.5 times the size of intake. I didn't know if it would provide enough negative pressure with the carbon filter.

Attachments

so series or parallel? lol, i have 2 Mechatronics 120x120x38mm High Speed AC Fans 106 cfm each max,my space is 31 inches tall,36 inches wide and 18 inches deep,cfl's totaling 249 watts(4-42's,and 3-27's) i wanna make a scrubber using kitty litter and carbon using my fans to pull the air from my cab thru the scrubber,trying to figure out if i should put the fans side by side or stacked