https://www.youtube.com/watch?v=mYM7u6ZEpls&feature=youtu.be

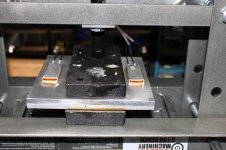

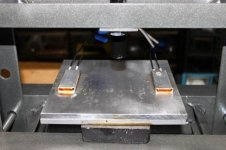

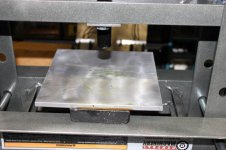

a video of press assembly and how it functions. no test squanches yet as I don't have any flower. May try a kief press to see how that goes.

a video of press assembly and how it functions. no test squanches yet as I don't have any flower. May try a kief press to see how that goes.