Sun, are you still using an ir thermometer?

-

As of today ICMag has his own Discord server. In this Discord server you can chat, talk with eachother, listen to music, share stories and pictures...and much more. Join now and let's grow together! Join ICMag Discord here! More details in this thread here: here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

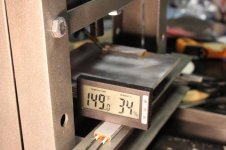

I experimented with something else today. An NTC Thermistor. This is the little resistor that goes in cheap digital thermometers for measuring temperature. I just ran this one out of the back of the device and sandwiched it in between the plates.

I ran into some problems but this looks like a real easy answer to monitoring the plates temperature during heat up. I need to run some comparison tests and when I tweak it in a little better, I'll post what I find.

I ran into some problems but this looks like a real easy answer to monitoring the plates temperature during heat up. I need to run some comparison tests and when I tweak it in a little better, I'll post what I find.

Attachments

im interested in this rosin budder...

Yeah, me too. What? Is it just lower temperature that's doing it? I pressed some at lower temp and just got less yield.

im interested in this rosin budder...

Roji, my man. What's up bro!

Yeah I screwed up, was prolly only about 130F 900psi. It yielded only like 2%. Then i went back a squished it again at about 150F and got more budder but it was darker and didn't super autobudder up. Then i pressed it again at 200F and got the last of it but I felt by this time it was pretty decarbed as the product was very sticky. Once i figure out design and be satisfied with it, ill figure out the relatuonship of time and temp. I will try more experiments in the future but this is getting costly to go big. Damn near blew through more than half a ki of kief.

I've wasted a lot of material these last 2 days. Everything works on a smaller scale, then when you go big shit gets way crazier. I think the internal pressure of the material when the oils start to run, increases exponentially with size.

My new design concept works but has many flaws as well. This shit is frustrating, I'm about to just go buy a hair iron and call it good lol!

By the way I figured out a sweet way of judging heat of the plates when your heat them on a stovetop. Just put a little puddle of water on there. As soon as you see little bubbles tour around 180F. Once the bubbles first start to break your about 200F. Then shortly after it erupts into a boil and your clearly at 212F. Was doing that today as my kiln heats so slow I was impatient to waste more material. I'm ordering that induction plate tomorrow!

Back over here now guys mwuahahaha!

So today's experiments yielded startling results. I did a 130 gram press going back to my old concepts, the new one I came up with I disliked more than the old one that I now went back to.

I'm over using the kiln, induction plate will hopefully be here in a week. So I'm using the stove top with the pool of water on it. The ir gun actually seems to read the water pretty accurately. So i waited until the pool erupted into a full boil, should indicate 212F and the ir gun confirmed that approximate temp. I ran to the press with plates in hand and gave her a go. There was no audible sizzle and the flow was slow, I let it sit there for seriously like 10 minutes, no signs of decarb as opposed to when I was doing 250F. I only got like a 25% return so I decided to repress at higher temps. This time I waited until the pool of water completely evaporated, then an extra ten seconds. This time there was slight audible sizzle and a tiny bit of vapor and smell. I yielded an additional 20 grams on top of the previous 35. The second press however is lighter color! Wait what? Yes it was noticeably lighter color right off the bat. Then, I noticed the end of the flow, closest to the plates, was damn near clear. No noticeable decarb via the sticky finger test (super analytical right?) Wtf is going on?!?!? I'm getting excited again realizing that this could be more of an art form. Heat, pressure, moisture, starting material, and I'm sure time plays a role too. So many variables, I hope we figure this all out some day. I will take pics and do a more thorough examination later.

I'm starting to get over the anti parchment thing, it makes things less accurate, less controllable, less efficient, and more prep and work. I got material for one last press. I'm going to take my high pressure/heavy filter bundle concepts, and use parchment instead of the all ss route. I'll let you guys know what I think.

Can anyone please give me insight as to whether or not it really is bad to use parchment? I can see all the theoretical possibilities but I have no facts. I have noticed that if I reuse parchment sometimes little fibers peel off and stick to the rosin. How much contamination is possible? How harmful can it really be with a low temp vape/dab?

BFP - hurry up and finish your work and publish your wife comment driven parchment free concept. I'm hoping you got something better and easier than I do. Maybe one day we can a have a rosin conference and sit down with everyone for a week and really come up with some good results. That'd be fun!

So today's experiments yielded startling results. I did a 130 gram press going back to my old concepts, the new one I came up with I disliked more than the old one that I now went back to.

I'm over using the kiln, induction plate will hopefully be here in a week. So I'm using the stove top with the pool of water on it. The ir gun actually seems to read the water pretty accurately. So i waited until the pool erupted into a full boil, should indicate 212F and the ir gun confirmed that approximate temp. I ran to the press with plates in hand and gave her a go. There was no audible sizzle and the flow was slow, I let it sit there for seriously like 10 minutes, no signs of decarb as opposed to when I was doing 250F. I only got like a 25% return so I decided to repress at higher temps. This time I waited until the pool of water completely evaporated, then an extra ten seconds. This time there was slight audible sizzle and a tiny bit of vapor and smell. I yielded an additional 20 grams on top of the previous 35. The second press however is lighter color! Wait what? Yes it was noticeably lighter color right off the bat. Then, I noticed the end of the flow, closest to the plates, was damn near clear. No noticeable decarb via the sticky finger test (super analytical right?) Wtf is going on?!?!? I'm getting excited again realizing that this could be more of an art form. Heat, pressure, moisture, starting material, and I'm sure time plays a role too. So many variables, I hope we figure this all out some day. I will take pics and do a more thorough examination later.

I'm starting to get over the anti parchment thing, it makes things less accurate, less controllable, less efficient, and more prep and work. I got material for one last press. I'm going to take my high pressure/heavy filter bundle concepts, and use parchment instead of the all ss route. I'll let you guys know what I think.

Can anyone please give me insight as to whether or not it really is bad to use parchment? I can see all the theoretical possibilities but I have no facts. I have noticed that if I reuse parchment sometimes little fibers peel off and stick to the rosin. How much contamination is possible? How harmful can it really be with a low temp vape/dab?

BFP - hurry up and finish your work and publish your wife comment driven parchment free concept. I'm hoping you got something better and easier than I do. Maybe one day we can a have a rosin conference and sit down with everyone for a week and really come up with some good results. That'd be fun!

just make sure you're using Reynolds parchment at the very least, all the other store brands that I've tried are porous to a certain degree, what I've noticed anyways.

I figured that's what you were talking about(the silicon or whatever it is that DuPont sprays on the paper)...I haven't noticed anything with the naked eye using the foil backed "pan lining" paper, but that certainly doesn't mean that traces of the coating may not be present. most concentrates involve parchment paper at some point or another for the most part so I guess I just don't think too deeply into it. I know that RAW makes parchment, ad I see a few people on IG using ptfe(I think??) paper...

the porosity is a drag, fwiw.

the porosity is a drag, fwiw.

GanjaPharma

Member

I stopped using parchment when i noticed fibers in some of my heavier pressed extractions.

Think they are from the PAPER breaking down, rather than any sort of "Coating". From what I have read, Parchment is a cellulose matrix saturated in silicone...so no top coating to speak of.

QUILON on the other hand IS a (water soluble) coating approved by the FDA and is often used in non-stick parchments.....now that will DEFINITELY get into your oil.

Think they are from the PAPER breaking down, rather than any sort of "Coating". From what I have read, Parchment is a cellulose matrix saturated in silicone...so no top coating to speak of.

QUILON on the other hand IS a (water soluble) coating approved by the FDA and is often used in non-stick parchments.....now that will DEFINITELY get into your oil.

I stopped using parchment when i noticed fibers in some of my heavier pressed extractions.

What are you using instead of parchment?

Parchment paper is used for baking, much hotter and longer exposure to the heat, so are the veggies or cookies reasonable safe, probably. Is there some chem reaction with the heat, pressure, and solvent properties of the terpenes who knows.

incorrect i believe GanjaPharma, virtually all parchment paper has a silicone layer on it. I did enough research to find this out. There are two kinds that do not, patapar paper, and regency parchment paper, which is 100% vegetable. I haven't tried patapar, its super costly and hard to get here, but the regency is a bitch to get the concentrate off. maybe i will try again sometime but first attempt was dismal as i recall.

silicone if heated to a certain temperature can create benzene, but that temp is above reasonable pressing temps, however if you are somehow adding some silicone to your extract when removing, when you vaporize that extract i imagine the silicone would get hot enough for sure.

silicone if heated to a certain temperature can create benzene, but that temp is above reasonable pressing temps, however if you are somehow adding some silicone to your extract when removing, when you vaporize that extract i imagine the silicone would get hot enough for sure.

GanjaPharma

Member

What are you using instead of parchment?

these days I am using Slick sheet (PTFE) and Oil Slick Pads / DUOs.

if using Slick pads DO NOT FOLD THEM.

use one on top of the other.

For smaller runs i squish it all between 2 DUO pads,

For larger runs I use a single large size pad, and multiple DUO pads. (4 or 5 presses onto the same pad in different spots)

I only use the OilSLick silicone because I trust the quality. Not just the silicone (medical grade) but the edges, and printing you see on other brands have peeled and cracked on me in the past. Oil Slick doesnt even put their logo on the pads because they worried about contamination....so they are perfect for this.

and nonstick as fuck

GanjaPharma

Member

PTFE works very very well also, I started buying it on a 50 foot roll for $140 bucks from Oil Slick directly. Compared to the price of a small roll ($20 for 4 feet) its HALF the price.

no good pics on my phone of the finished extraction, but here is an envelope after the first brief low temp press. I stick it back in for a massive squish afterwards...but forgot to get a picture:

the slick sheet has the advantage of being:

1)disposable

2) more flexible than paper

but requires a different approach on collection than silicone. a bit of work with hot plate and cold pack.

later today ill take pics of how i transfer from PTFE to silicone using heat (silicone side) and cold (ptfe side)

to stick, peel , and gather.

no good pics on my phone of the finished extraction, but here is an envelope after the first brief low temp press. I stick it back in for a massive squish afterwards...but forgot to get a picture:

the slick sheet has the advantage of being:

1)disposable

2) more flexible than paper

but requires a different approach on collection than silicone. a bit of work with hot plate and cold pack.

later today ill take pics of how i transfer from PTFE to silicone using heat (silicone side) and cold (ptfe side)

to stick, peel , and gather.

Yeah I was going to move the ptfe route. Anyone know if there are thin sheets of ptfe available. Like the thickness of those thin roll up cutting boards. That would be super boss.

I'm digging the sustainability of those pads. Do you see any minor degradation yet? I wonder how long they will last.

I'm digging the sustainability of those pads. Do you see any minor degradation yet? I wonder how long they will last.

GanjaPharma

Member

Yeah I was going to move the ptfe route. Anyone know if there are thin sheets of ptfe available. Like the thickness of those thin roll up cutting boards. That would be super boss.

I'm digging the sustainability of those pads. Do you see any minor degradation yet? I wonder how long they will last.

yes I toss the pads if they show ANY wear and tear.

Flat pressing doesnt damage them, but sometimes if i have a high spot on the inside packet it causes excessive pressure in one tiny area, and the pad can get "dented".

I havent seen what happens next, I just chuck them in the trash and get another.

DUO pads (the small ones) come 2 in a package. they are $10 (2pc) online, but you can buy a case of 25 for $160...

and if you use the ICMAG code you get 20% off w free shipping....so $125 for 25 (2 pack)....come out to like $2.50 each

if i had to take a guess...Id say i get at least 10 runs out of a single pad before i see anything

GanjaPharma

Member

Yep. Was posted somewhere on here like two years ago.

Been using it ever since

ICMAG at checkout...and for case prices there's a drop-down.

Had to call them direct for the big rolls

Been using it ever since

ICMAG at checkout...and for case prices there's a drop-down.

Had to call them direct for the big rolls

They look like 12" wide is that correct?

Do you know how thick they are? I think I've found rolls other places for half that price.

.002 x 12 x 50 feet for 55$ before tax and shipping

.004 x 12 x 50 feet for 111$ before tax and shipping.

I went for a 20 foot roll of the .002 for 28$.

I ordered some .015 to play with as opposed to using the silicone slick mats. Idk how well it will hold up but I'll let you guys know.

Look whadeezlrg this is like my fourth edit to this post and I didn't make any new ones. Come on dude gimme a gold star or something already!

Lmao anyways...I just did a bunch more looking around. I ordered from professional plastics and for being inside the United states, with fast shipping options, they have the best prices, not the best selection though. Ptfe of all thickness have the same 1500 psi tinsel strength. .002 looks standard for the baking industry so that's good. I saw some as thin as .001 and some as thick as .005 but most were .002. I called their closest office in Sacramento. They got a lot down there, next time of order more I'm just going to drive down there and try to get a better deal. The website gives limited options she told me because it makes It easy for like 20 different warewhouses. She said she could cut me any size of whatever I wanted, even could just pick up whole rolls. Sold by the pound, could probably get a good deal on a 100 pack!

Do you know how thick they are? I think I've found rolls other places for half that price.

.002 x 12 x 50 feet for 55$ before tax and shipping

.004 x 12 x 50 feet for 111$ before tax and shipping.

I went for a 20 foot roll of the .002 for 28$.

I ordered some .015 to play with as opposed to using the silicone slick mats. Idk how well it will hold up but I'll let you guys know.

Look whadeezlrg this is like my fourth edit to this post and I didn't make any new ones. Come on dude gimme a gold star or something already!

Lmao anyways...I just did a bunch more looking around. I ordered from professional plastics and for being inside the United states, with fast shipping options, they have the best prices, not the best selection though. Ptfe of all thickness have the same 1500 psi tinsel strength. .002 looks standard for the baking industry so that's good. I saw some as thin as .001 and some as thick as .005 but most were .002. I called their closest office in Sacramento. They got a lot down there, next time of order more I'm just going to drive down there and try to get a better deal. The website gives limited options she told me because it makes It easy for like 20 different warewhouses. She said she could cut me any size of whatever I wanted, even could just pick up whole rolls. Sold by the pound, could probably get a good deal on a 100 pack!