Sun, I forgot the comma, Eldon came up with the idea in Kathmandu in the early 90's.

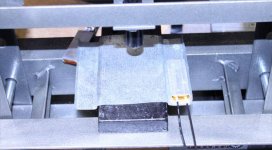

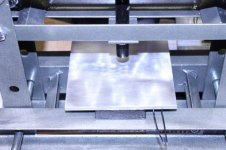

All we need is a device with hot plates and pressure without safety...

Wow I never knew that...so, is he not walking this plane any longer?

Yeah that's pretty much it, the less safety the better I say. Lets give the cls operators more job security and the press more shit to instill fear in the hearts of the viewers. That lanbc piece about the bho "epidemic" needs to be repeated for rosin!