Ringdoggie:

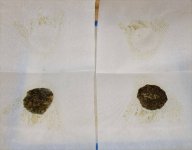

What did you think of the extract from re-pressing your used flower/sift pucks...

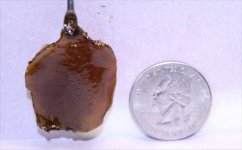

It was darker and it's a pain in the ass to work with because it is so sticky. The first press was more like shatter. I could roll it in my fingers and break a piece off for the nail. But the second press was real sticky. Albeit, I might have pressed it longer or harder to cause that.

I smoked some this morning and it seems OK. I don't really get high any more so it's hard to tell. Taste was similar but not as sweet.

One thing for sure. This rosin sure burns faster than any BHO I ever had. I can empty a bowl of this in 5 or 6 hits. BHO seemed to last forever in the bowl.