GW,

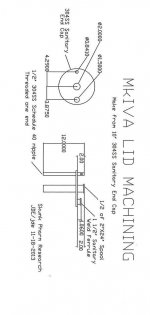

How about recovery times running passive? i hate using a recovery pump on my IFE, but looking forward to running the MKIV.

I've never run a Mk IV passively, but the Lil Terp took about 1 hour 45 minutes running 110F and a regular ice bath. Folks have cut it to 30 minutes, or so, using dry ice/alcohol for the recovery bath.