Malawi Style Cob Curing.

- Thread starter Thread starter Tangwena

- Start date Start date

ZanzibarDawa

Member

tobaco-leaf cob with freshly plugged, fully riped virginia leafes and a good hand full of malawi. looks almost like a turkish dolma : )

https://www.icmag.com/ic/picture.php?albumid=66529&pictureid=1611824View Image https://www.icmag.com/ic/picture.php?albumid=66529&pictureid=1611825View Image https://www.icmag.com/ic/picture.php?albumid=66529&pictureid=1611826View Image https://www.icmag.com/ic/picture.php?albumid=66529&pictureid=1611827View Image https://www.icmag.com/ic/picture.php?albumid=66529&pictureid=1611828View Image

This is really interesting. I'm sure it will work, but am most interested to see whazt state the tobacco is in after the cure.

We might learn something from the classical tobacco curing method. Any chance you could try an experiment with a pure tobacco cob? Just for comparison to differently cured tobacco.

ZD

subrovka

Member

This is really interesting. I'm sure it will work, but am most interested to see whazt state the tobacco is in after the cure.

We might learn something from the classical tobacco curing method. Any chance you could try an experiment with a pure tobacco cob? Just for comparison to differently cured tobacco.

ZD

i´m gonna leave this cob in my closet where it´s dark and dry until the tobaco leaf is fully yellow and more or less dry (about 2 weeks). this approach will be without vacuum-bag, i´ll try to use a dried tobacco leaf with sweat cure in vacuum bag the next time..i really enjoy stuff like that

..you mean to sweat-cure a pure tobacco cob?

lemonskunk

Member

Hey Sforza you troll I didnt say smoking pot is dangerous. I doubt Willie has a compromised immune system or buys moldy weed.

You might have noticed if you werent so high off your ass from smoking black mold spores (Im just kidding)...I only used the word dangerous in the comparison of smoking the contaminated marijuana to eating the contaminated marijuana. Certain molds produce chemicals called aflatoxins.

af·la·tox·in

nounCHEMISTRY

noun: aflatoxin; plural noun: aflatoxins

any of a class of toxic compounds that are produced by certain molds found in food, and can cause liver damage and cancer.

Combustion would probably destroy these compounds. Eating them would destroy your liver. Can you guess which one is more DANGEROUS?

You might have noticed if you werent so high off your ass from smoking black mold spores (Im just kidding)...I only used the word dangerous in the comparison of smoking the contaminated marijuana to eating the contaminated marijuana. Certain molds produce chemicals called aflatoxins.

af·la·tox·in

nounCHEMISTRY

noun: aflatoxin; plural noun: aflatoxins

any of a class of toxic compounds that are produced by certain molds found in food, and can cause liver damage and cancer.

Combustion would probably destroy these compounds. Eating them would destroy your liver. Can you guess which one is more DANGEROUS?

ZanzibarDawa

Member

i´m gonna leave this cob in my closet where it´s dark and dry until the tobaco leaf is fully yellow and more or less dry (about 2 weeks). this approach will be without vacuum-bag, i´ll try to use a dried tobacco leaf with sweat cure in vacuum bag the next time..i really enjoy stuff like that

..you mean to sweat-cure a pure tobacco cob?

I am not too sure that it will work without a vac bag. You need the anaerobic conditions for the cob cure to work. Too much oxygen is probably THE biggest risk with these kinds of fermentation.

For that reason tobacco is tightly packed in big heaps and silage is compressed with very heavy machinery and covered to limit exposure to oxygen to the absolute minimum.

Yes, sweat curing a pure tobacco cob, please do it for science

ZD

subrovka

Member

hm..ok thanks for the advice! well, i´m going to sweat it now and then vacuum it..i was thinking maybe the wet, tightly bound tobaco leaves could keep enough oxygen out for anaerobic conditions in the inside of the cob but don´t wanna risk mold as everything was still quite wet!

i´m gonna make a tobaco cob tomorrow and post some pics here, just plugged a good staple of ripe leafes today

i´m gonna make a tobaco cob tomorrow and post some pics here, just plugged a good staple of ripe leafes today

Cannabliss420

Member

I am not too sure that it will work without a vac bag. You need the anaerobic conditions for the cob cure to work. Too much oxygen is probably THE biggest risk with these kinds of fermentation.

For that reason tobacco is tightly packed in big heaps and silage is compressed with very heavy machinery and covered to limit exposure to oxygen to the absolute minimum.

Yes, sweat curing a pure tobacco cob, please do it for scienceI'd be very excited to see the results!

ZD

I see. I don't have a vacuum sealer as well just yet. I tried a 1.1g mini cob with some Platinum Cherry Pie just recently. Just not in a corn husk. All I had is parchment paper

I'm currently keeping it in a baggie with 62% Boveda packs. I'm not too worried about mold in this fashion as the bud is dry enough to smoke but still wet to the touch and alot of bud is cured in a similar fashion, we will see. Probably at 20% moisture I'm assuming as I work with hundreds of lbs a day at my job site and have a moisture analyzer onsite.

Other than the vacuum sealer, what recommendations would you have for a small "cob" like this?

The sweating will most likely not occur with the boveda packs in the bag so all you will get is bound up buds. The sweating and oxygen free curing are the whole point. If you dont have those you just have buds bound up in parchment paper unfortunately. If you want to experiment fine but if you want a proper sweat cure you have to have the correct conditions.

Tangwena

Tangwena

Cannabliss420

Member

I see

corn husks are easy to get in the fall. you can dry and store in zip lock gallon bags enough for the future. if they get brittle rehydrate, not too much though.

the thrift shops here have lots of brand new, never used vacuum sealers available often. gifts me think.

a food dehydrator with dial temperature controls is probably excellent for sweating cobs in the winter or late late fall. you can cut out the webbing in the trays so that you can stack a bunch of trays with the webbing removed for a deep reservoir to hold lots of cobs at one time. I use the food dehydrator very successfully for purging wax and hash concentrates. these are also available dirt cheap quite often at thrift stores in my area. wallmart still sells this stuff very inexpensively as well.

the thrift shops here have lots of brand new, never used vacuum sealers available often. gifts me think.

a food dehydrator with dial temperature controls is probably excellent for sweating cobs in the winter or late late fall. you can cut out the webbing in the trays so that you can stack a bunch of trays with the webbing removed for a deep reservoir to hold lots of cobs at one time. I use the food dehydrator very successfully for purging wax and hash concentrates. these are also available dirt cheap quite often at thrift stores in my area. wallmart still sells this stuff very inexpensively as well.

DEATH BY SNUSNU

Member

For me cobbing defies logic but I meditated on this. I read somewhere that the plant is alive until it is dry dry dry like bone. So could the anaerobic environment be off gassing things that the dying flower/plant craves? Is there a surge of concentrated ammonia, co2 or o2 fueling the further maturationg and or production of cannabinoids? Accelerated and or extensive amberring? It totaly sounds like this process is extending the life of the plant in a super controlled environment. Any one?

Thanks for this thread, and I read it all!

Cant wait to cob some Malawi!

As for the people suggesting it's dangerous, mold ridden, crap.....

Take the death grip off a dam Buck if you can,

And pay to have it checked.... its its poison, then and only then report back.. until then, gtfoh....

Thxs again for the education.

Cant wait to cob some Malawi!

As for the people suggesting it's dangerous, mold ridden, crap.....

Take the death grip off a dam Buck if you can,

And pay to have it checked.... its its poison, then and only then report back.. until then, gtfoh....

Thxs again for the education.

it's a fermentation process, which relies on present enzymes and native microorganisms to convert certain chemical elements in the plant material to other forms, ideally something tastier or more palatable.

i wouldn't be surprised if major decarboxylation occurred during the sweating process.

i tried to find something on tobacco curing that would shed some light on what may be happening in our cobs.

i wouldn't be surprised if major decarboxylation occurred during the sweating process.

i tried to find something on tobacco curing that would shed some light on what may be happening in our cobs.

Tobacco curing is an important process in the industry. The procedure followed varies from one place to another and from one country to another. Certain enzymatic activities take place in the curing process, which brings about a distinct change in the chemical composition of the leaf. Some bacteria are believed to play a significant role in the fermentative process that sets in the curing of tobacco leaves. When the leaves are harvested and piled in heaps, the temperature rises to about 60*C. Certain thermophilic bacteria are believed to become active at this temperature. The enzymatic activity that sets in, helps in the development of typical aroma and flavour in the tobacco leaves. The alkaloids and organic acids are attacked, resulting in some better quality chemicals. Over 1,000,000 bacteria have been estimated in 1 gm of tobacco leaf. Several species of Bacillus, Proteus vulgaris, and some thermophilic organisms are commonly encountered. However, the exact role of these organisms in the biochemical changes during the curing process has not been worked out in any detail. Because of the varying types of soils in which tobacco is cultivated, and the different procedures that are being followed to cure the leaves, large variations in the microbial populations on the fresh leaves, and their subsequent role in curing are believed to take place.

Agricultural Microbiology by D. J. BAGYARAJ, G. RANGASWAMI pp 381

it's a fermentation process, which relies on present enzymes and native microorganisms to convert certain chemical elements in the plant material to other forms, ideally something tastier or more palatable.

i wouldn't be surprised if major decarboxylation occurred during the sweating process.

i tried to find something on tobacco curing that would shed some light on what may be happening in our cobs.

So... it is "magic", even with a legal and well studied smoke. All we know is... it's good.

lemonskunk

Member

If tangwena is chewing it to get high as he says, then for sure major or complete decarboxylation has occurred.

DEATH BY SNUSNU

Member

I would like to see a mico vid of the stomata if they are moving and close ups of the glands. I don't think dead plants amber, I believe it to be a last push, before death and the curing reactions taking place. The potency increase is just fascinating.

If anyone was worried about mold issues , if need be you could wash your flowers after clip in h202 water and rinse in water again to get any spores off or what have you.

If anyone was worried about mold issues , if need be you could wash your flowers after clip in h202 water and rinse in water again to get any spores off or what have you.

subrovka

Member

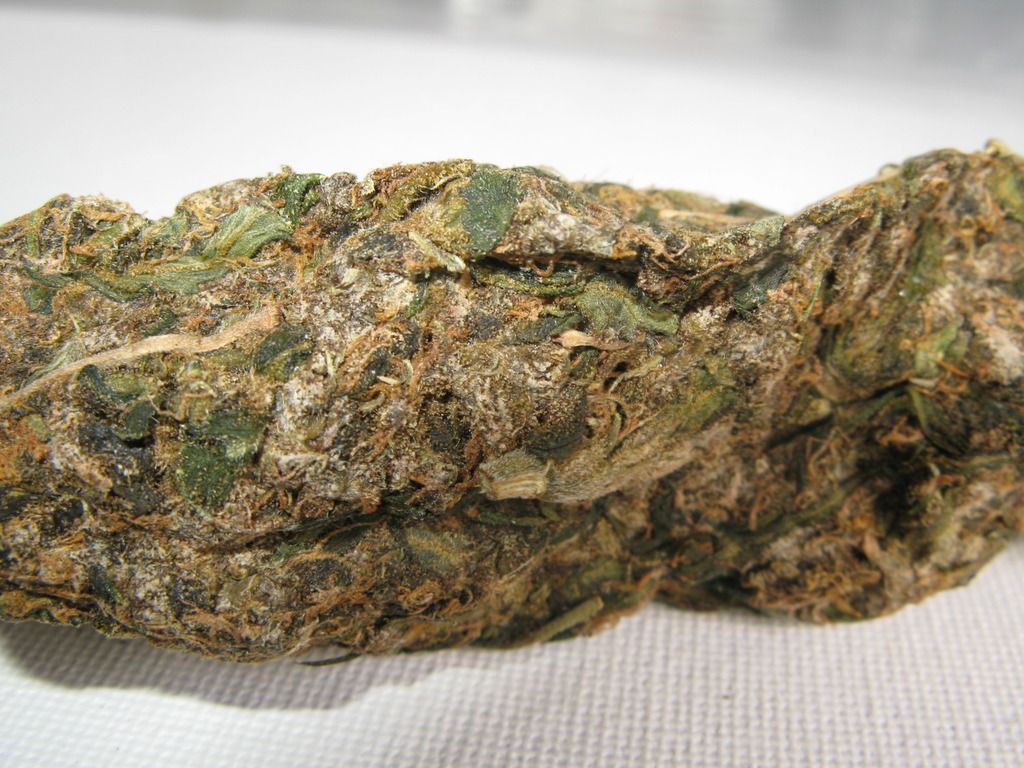

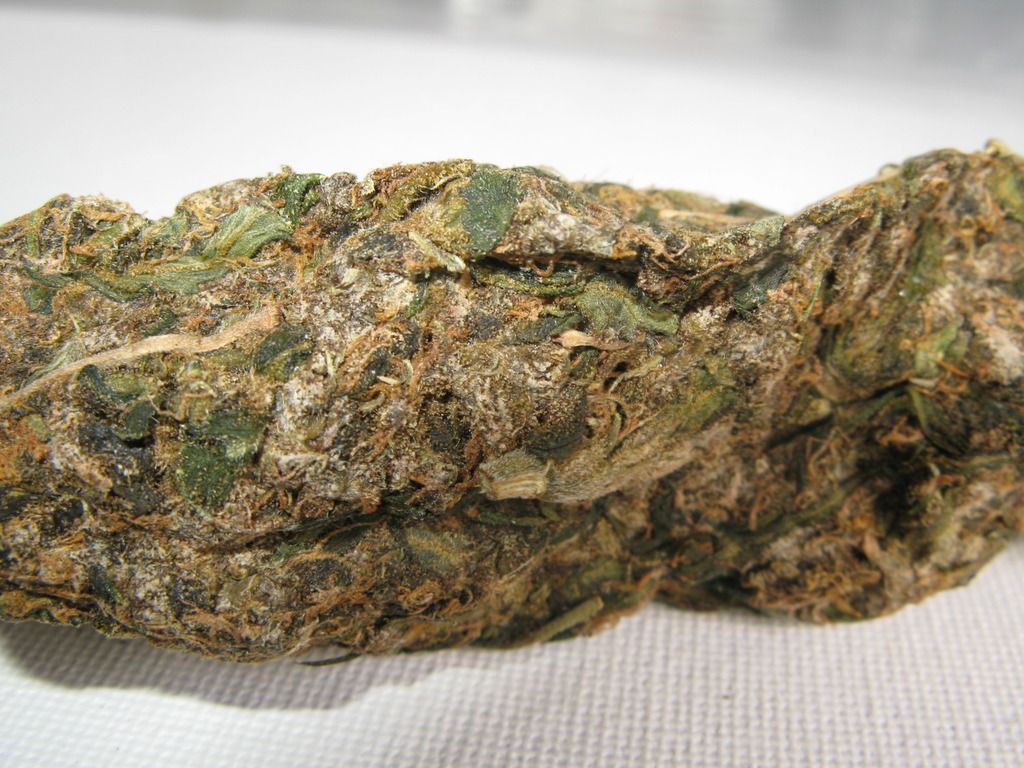

..opened one of my malawi cobs today after only 4 (and a half) days..i was just too curious hehe..made a lot of cobs with different drying stages of the bud.

this one went in pretty wet and had a good sweat. it is pretty much compressed, weights 40g but is also still too wet to smoke. the trichs are already completely milked up and there´s a lot of amber too. my camera is not the best but i checked under a scope and the results after only 4 days of sweat curing is amazing!

this one went in pretty wet and had a good sweat. it is pretty much compressed, weights 40g but is also still too wet to smoke. the trichs are already completely milked up and there´s a lot of amber too. my camera is not the best but i checked under a scope and the results after only 4 days of sweat curing is amazing!