Video of the Haskel in action, Mk VB SN-0009, "Mad Shatter,"

https://www.facebook.com/video.php?v=1706865996207037&set=vb.1557888421104796&type=2&theater

Thanks for the post SH! We will take a video camera next time, instead of using a phone.

I also had problems with my camera, namely my batteries died and and bled enough wipe out my peach keen Nikon flash, so I had to rely on the small one on my obsolete D-80 at ISO 1600.

Alas next I found my card corrupted when I got home and tried to down load. I was finally able to do so, with more elaborate efforts, and was disappointed at the quality of the pictures in a dim warehouse. I will Photo Shop them and see what I can salvage when I get time, and share.

Mad Shatter is arguably the most sophisticated Mk V that WolfWurx has put out from a feature stand point, despite not being automated, as it also has the latest trap/drier, and the Haskel is set up selectable between single and double stage.

Mad Shatter also features an old news triple core alcohol/DI heat exchanger, and each side of the Haskel has its separate 3/8" X 20' coil to cool down the pump discharge before passing through the water trap and drier, followed by a pass through another 3/8" X 50' coil prior to enter the storage tank.

Temperature at the discharge to the tank typically read from -15F to 27F, during our distilling off two Lp-5's of 99.5% Instrument grade butane from CT, at the average rate of .36 lbs/min, followed by a cleaning run and a production run, after swapping out the lower tank.

The distillation did produce MO, but in impressively small quantities as viewed through the LED lit sight glass, so we waited to clean it until after the cleaning run, leaving it mixed with oil extracted from the low grade trim we used, in lieu of the spent material we typically use at the pup farm.

It all gets washed out with hot denatured alcohol and discarded, as it also contains the systems oils and manufacturing debris.

There were no issues with running full cycles with the Haskel in single stage, with the heat exchangers, because tank pressure hovered between zero and 5 psi, so the Haskel easily pulled -22" Hg.

It did stall out recovering the butane in the line between its normal discharge and the storage tank, using a valved circuit, which has provisions to pump the recovered butane into a stand by cylinder.

I erroneously didn't put that in an ice bath, and when the Haskel started stalling out, I felt the tank to see if it was warm, and it was beyond warm and ostensibly reaching 200 psi internal pressure, because I had the 4:1 Haskel set at 50 psi.

I iced the Lp-5 I was recovering into, and switched the Haskel to double stage, after which it again steadily pumped away until -22" Hg was reached in the recovered circuit.

As a point of interest, it salvages the butane in the lines, trap/drier, and heat exchanger coils, which is starting to be significant.

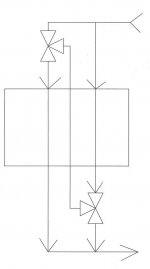

Using bushings, two 1/2" 3-way valves, and a jumper hose works slick for switching the Haskel from single to double stage.

Of note, is that I picked 50 psi because that was all I needed to achieve about 60 strokes a minute at the back pressure I had. It is hard to exert more pressure on something that isn't pushing back.

Here is a picture of the first production run of what the proud new owner considered his low grade trim, but which put a smile on his face after I fluffed it up into a light colored cotton candy, after a flawless extraction.

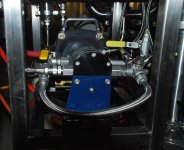

The operation ended up containing extra steps, which included installing the owners new 10 Hp 3ph Chicago Pneumatic screw compressor/refrigerative drier/receiver from Portland Compressor.

It wouldn't turn on after install, so we had to wait for Portland Compressor to open up the next day to get hold of a technician, because there was no "destruction manual" included, only a CD that was hard to read in the field with just a flash light.

Fortunately the technician's suggestion that we check for reverse polarity was a good one, especially after he revealed the location of the reset button, so we could get it to run long enough to check rotation. After reversing the two outside legs, wooooooup, whirrrrrrrrrrrrrrrrrrrr.

Impressively quiet, as compared to the 200 hp jobs I typically installed in new facilities prior to retirement. No problem at all standing next to it while running, and the combination of it and Mad Shatter's Haskel were no where near damaging ranges, though less endearing than the sound of silence long term.

Never thought playing "The Oregon Trail" on MS DOS, as a kid, it would actually be like this ... lol

Never thought playing "The Oregon Trail" on MS DOS, as a kid, it would actually be like this ... lol