-

ICMag with help from Phlizon, Landrace Warden and The Vault is running a NEW contest for Christmas! You can check it here. Prizes are: full spectrum led light, seeds & forum premium access. Come join in!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The hemp seed hub: A thread for those who seek seeds and infos on hemp

- Thread starter Only Ornamental

- Start date

& can someone explain ?

if i use S1's / Fem tech in breeding program after say ten generations you run into issues ?

how do you recover ? scrap the line ?

each generation selecting also moves further from vigor etc.

-----------

Sam , have you test the same line simultaneously ? S1 / Fem against traditional pedigree / line breeding then after many generations tested results between those ?

if i use S1's / Fem tech in breeding program after say ten generations you run into issues ?

how do you recover ? scrap the line ?

each generation selecting also moves further from vigor etc.

-----------

Sam , have you test the same line simultaneously ? S1 / Fem against traditional pedigree / line breeding then after many generations tested results between those ?

Robert C. Clarke/Mark D. Merlin

...... Humans and the Cannabis plant share an intimate history spanning millennia. Humans spread Cannabis from its Eurasian homelands throughout much of the world, and, in concert with local climatic and human cultural parameters, created traditional landrace varieties (cultivars resulting from a combination of natural and farmer selection) with few apparent signs of domestication. Cannabis breeders combined populations from widely divergent geographical regions and gene pools to develop economically valuable fiber, seed, and drug cultivars, and several approaches were used with varying results. The widespread use of single plant selections in cultivar breeding, inbreeding, and the adoption of asexual reproduction for commercial drug production, reduced genetic diversity and made many present-day cultivars susceptible to pathogens and pests. The great majority of drug Cannabis cultivars are now completely domesticated, and thus are entirely dependent on humans for their survival. Future ramifications remain to be realized.........

http://www.tandfonline.com/doi/abs/10.1080/07352689.2016.1267498?journalCode=bpts20

...... Humans and the Cannabis plant share an intimate history spanning millennia. Humans spread Cannabis from its Eurasian homelands throughout much of the world, and, in concert with local climatic and human cultural parameters, created traditional landrace varieties (cultivars resulting from a combination of natural and farmer selection) with few apparent signs of domestication. Cannabis breeders combined populations from widely divergent geographical regions and gene pools to develop economically valuable fiber, seed, and drug cultivars, and several approaches were used with varying results. The widespread use of single plant selections in cultivar breeding, inbreeding, and the adoption of asexual reproduction for commercial drug production, reduced genetic diversity and made many present-day cultivars susceptible to pathogens and pests. The great majority of drug Cannabis cultivars are now completely domesticated, and thus are entirely dependent on humans for their survival. Future ramifications remain to be realized.........

http://www.tandfonline.com/doi/abs/10.1080/07352689.2016.1267498?journalCode=bpts20

I just follow the current development in SwitzerlandCan you quote me the law that prohibits using pesticide on a hemp crop? I never heard of this and I have grown hemp in the EU & Switzerland and elsewhere for decades outdoors by the hectare. Do "you" really grow hemp by the multi hectare in the EU or Switzerland? If yes for how many years?

Non-EU approved hemp varieties can be grown outdoors. I do it all the time.

Are you really a hemp farmer Only Ornamental? I am.

You talk like you have limited experience actually growing large quantities of hemp, excuse me if I am wrong.

-SamS

I'm not a hemp farmer and without an additional formation or study I couldn't even become one in Switzerland. At first, it seemed possible to grow high CBD hemp and was a strong point to move to Switzerland but it was only possible during a year or two, just between to changes in legislation. I could however work with a farmer (subcontract the grow and that's what many do). I'd like to grow high CBD, though but without the proper cash for a reasonably large indoor plantation to start with...

See also HERE and HERE (French and Italian versions are also available, not English though) for the most current development: See linked PDFs at the bottom of the pages. For about three years it's in constant change. New regulations are to be expected soon. Till then, some sort of uncontrolled CBD rush/scam is flourishing.Different countries have different regulations on what is allowed, Switzerland I believe allows 1% THC? 1% is correct. But if a variety is less then .3 or .2% THC it can be allowed in most of the EU. Yes it can and in the last few years several new varieties have been registered (over 50 are on that list). You can only get EU subsidies for EU listed hemp varieties, and as most hemp growers made more from the subsidies then from selling the crop, EU listed varieties are important to farmers. Swiss law allows only the plantation of either varieties on the Swiss list (which contains not a single hemp variety) and since a few years also EU varieties. In Switzerland, there are no subsidies for hemp, no matter what.

In the end CBD will be produced by high CBD varieties with very low THC levels, why grow 10 times the area of plants to get the same amout of CBD? I have seen 25% CBD varieites and have heard of 30% CBD varieties, why grow hemp that yields 1-2% CBD? Correct, but there are no such varieties on the EU list. The 1% rule hence only applies to privately planted hemp and that hemp can not be sold. The loophole is to grow without sunlight and thereby avoiding the EU approved variety restriction imposed by the agricultural department. Such hemp can be a non-EU variety and if grown on industrial zones is allowed for sale. In Switzerland, CBD is not approved for cosmetics in accordance with an ancient document signed in the '60 in the USA (too tired to remember where and when exactly) which states anything derived from Cannabis (i.e. flowering material) is prohibited. The loophole here is exploited by SwissCBD (iFame) which now use only stalks and leaves to extract CBD for use in cosmetics. Absolutely stupid but the only way...

Hemp is for fiber, hurds, seeds, CBD is a small by product that can be produced more efficently by very high CBD varieties and in the end will be. I also believe that any CBD production will be from all female seeds or clones, seeded Cannabis does not produce as high of levels of Cannabinoids as unseeded Cannabis.

-SamS

Most standard testing is after seed set, if you grow seedless that may not be permitted, and even if allowed a seedless hemp crop may have a little to much THC to be permitted. If you are planning to grow a high CBD seedless crop to increase the CBD yield you will need to be sure the THC levels are still going to be under 1% or .2% or .3% THC whatever the local limit is in your area. For this reason it is good to grow high CBD varieties that are well below the THC limits, like .01% THC as there is little that can drive the THC% to illegal levels, like growing the variety unseeded.

-SamS

-SamS

& never forget. if you hear high percentage numbers for cbd / thc compliance please ask about testing times for these numbers. all states vary. in the future, a state may test ' hemp ' ( non-fiber ) at end of flowers etc this would eliminate many seed lines

- Kompolti hybrid TC: Hungary, F1 of the Chinese 'Kinai unisex' (dioecious 'Kinai Ketlaki' x monoecious 'Kinai Egylaki') x 'Kompolti', phenotypically dioecious, late flowering onset, high quality essential oil

What is meant with essential oil, the terpenes or the fatty acids?

socioecologist

Member

Most standard testing is after seed set, if you grow seedless that may not be permitted, and even if allowed a seedless hemp crop may have a little to much THC to be permitted. If you are planning to grow a high CBD seedless crop to increase the CBD yield you will need to be sure the THC levels are still going to be under 1% or .2% or .3% THC whatever the local limit is in your area. For this reason it is good to grow high CBD varieties that are well below the THC limits, like .01% THC as there is little that can drive the THC% to illegal levels, like growing the variety unseeded.

-SamS

Are there any high CBD varieties that finish at 0.01%? I know you have more experience than anyone with this Sam, but we haven't encountered a higher ratio than 50:1 on finished, unseeded flowers. If testing occurs a few weeks before harvest, a farmer can still pass with flying colors at the 0.3% THC threshold.

We have been able to produce plants with THC concentrations at less than 0.1% THC, but they are pure CBG. Now that CBD production is more mainstream, the critical determinant of economic efficiency is total CBD %. A field of 2% CBD plants has more use as green compost in the states than for oil extraction.

Essential oil means volatile oil e.g. mono- and sesquiterpenes (see Wiki for a definition). Quality was determined by subjective olfactory perception.What is meant with essential oil, the terpenes or the fatty acids?

Essential oil means volatile oil e.g. mono- and sesquiterpenes (see Wiki for a definition). Quality was determined by subjective olfactory perception.

Dutch word is etherische olie or in German Ätherische Öle, but in English the word essential oil is used by some for fatty acids as well.

The Genetic Structure of Marijuana and Hemp

Cannabis is one of humanity’s oldest crops, with records of use dating to 6000 years before present. Possibly because of its early origins, and due to restrictions on scientific inquiry brought about by drug policy, the evolutionary and domestication history of Cannabis remains poorly understood. Hillig (2005) proposed on the basis of allozyme variation that the genus consists of three species (C. sativa, C. indica, and C. ruderalis) [1], whereas an alternative viewpoint is that Cannabis is monotypic and that observable subpopulations represent subspecies of C. sativa [2]. The putative species C. ruderalis may represent feral populations of the other types or those adapted to northern regions.

The classification of Cannabis populations is confounded by many cultural factors, and tracing the history of a plant that has seen wide geographic dispersal and artificial selection by humans over thousands of years has proven difficult. Many hemp types have varietal names while marijuana types lack an organized horticultural registration system and are referred to as strains. The draft genome and transcriptome of C. sativa were published in 2011 [3], however until now there has been no published investigation of Cannabis population structure using high-throughput genotyping methods. As both public opinion and legislation in many countries shifts towards recognizing Cannabis as a plant of medical and agricultural value [4], the genetic characterization of marijuana and hemp becomes increasingly important for both clinical research and crop improvement efforts.

An important first step towards deeper evolutionary and functional analyses of Cannabis, including trait mapping and identification of functional genetic variation, is the characterization of the genetic structure of the genus. Here, we report the genotyping of a diverse collection of Cannabis germplasm and show that genetic differences between hemp and marijuana are not limited to genes involved in THC production, while the reported C. sativa and C. indica ancestries of marijuana strains only partially capture the main axes of marijuana’s genetic structure.

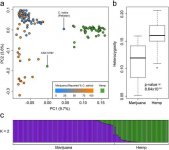

To evaluate the genetic structure of commonly cultivated Cannabis, we genotyped 81 marijuana and 43 hemp samples using genotyping-by-sequencing (GBS) [5]. The marijuana samples represent a broad cross section of modern commercial strains and landraces, while the hemp samples include diverse European and Asian accessions and modern varieties. Although we sampled a diverse collection of cannabis types in our study, access to samples is complicated by the fact that marijuana is an illicit drug and there are limited repositories of hemp germplasm in international seedbanks. In total, 14,031 SNPs were identified after applying quality and missingness filters. Principal components analysis (PCA) of both marijuana and hemp (Fig 1a) revealed clear genetic structure separating marijuana and hemp along the first principal component (PC1). This distinction was further supported using the fastSTRUCTURE algorithm [6] assuming K = 2 ancestral populations (Fig 1c). PCA and fastSTRUCTURE produced highly similar results: a sample’s position along PC1 was strongly correlated with its group membership according to fastSTRUCTURE at K = 2 (r2 = 0.98; p-value < 1 x 10−15).

We observe a putative C. indica marijuana strain from Pakistan that is genetically more similar to hemp than it is to other marijuana strains (Fig 1a). Similarly, the hemp sample CAN 37/97 clusters more closely with marijuana strains (Fig 1a). These outliers may be due to sample mix-up or their classification as hemp or marijuana may be incorrect. The sample of CAN 37/97 that we genotyped was from a Canadian hemp germplasm collection, which obtained this accession from the IPK Genebank (Gatersleben, Germany). The original source country is France but there is limited information to indicate the cultivation of CAN 37/97 as hemp. Alternatively, these samples may be true outliers and represent exceptional strains that are genetically unlike others in their group. Using the current data set, the unambiguous identification of a sample as either hemp or marijuana would be possible in the former case, but not in the latter. In any case, we find that the primary axis of genetic variation in Cannabis differentiates hemp from marijuana.

These results significantly expand our understanding of the evolution of marijuana and hemp lineages in Cannabis. Previous analyses have shown that marijuana and hemp differ in their capacity for cannabinoid biosynthesis, with marijuana possessing the BT allele coding for tetrahydrocannabinolic acid synthase and hemp typically possessing the BD allele for cannabidiolic acid synthase [7]. As well, transcriptome analysis of female flowers showed that cannabinoid pathway genes are significantly upregulated in marijuana compared to hemp, as expected from the very high THC levels in the former compared to the latter [3]. Our results indicate that the genetic differences between the two are distributed across the genome and are not restricted to loci involved in cannabinoid production. In addition, we find that levels of heterozygosity are higher in hemp than in marijuana (Fig 1b; Mann-Whitney U-test, p-value = 8.64 x 10−14), which suggests that hemp cultivars are derived from a broader genetic base than that of marijuana strains and/or that breeding among close relatives is more common in marijuana than in hemp.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4550350/

Cannabis is one of humanity’s oldest crops, with records of use dating to 6000 years before present. Possibly because of its early origins, and due to restrictions on scientific inquiry brought about by drug policy, the evolutionary and domestication history of Cannabis remains poorly understood. Hillig (2005) proposed on the basis of allozyme variation that the genus consists of three species (C. sativa, C. indica, and C. ruderalis) [1], whereas an alternative viewpoint is that Cannabis is monotypic and that observable subpopulations represent subspecies of C. sativa [2]. The putative species C. ruderalis may represent feral populations of the other types or those adapted to northern regions.

The classification of Cannabis populations is confounded by many cultural factors, and tracing the history of a plant that has seen wide geographic dispersal and artificial selection by humans over thousands of years has proven difficult. Many hemp types have varietal names while marijuana types lack an organized horticultural registration system and are referred to as strains. The draft genome and transcriptome of C. sativa were published in 2011 [3], however until now there has been no published investigation of Cannabis population structure using high-throughput genotyping methods. As both public opinion and legislation in many countries shifts towards recognizing Cannabis as a plant of medical and agricultural value [4], the genetic characterization of marijuana and hemp becomes increasingly important for both clinical research and crop improvement efforts.

An important first step towards deeper evolutionary and functional analyses of Cannabis, including trait mapping and identification of functional genetic variation, is the characterization of the genetic structure of the genus. Here, we report the genotyping of a diverse collection of Cannabis germplasm and show that genetic differences between hemp and marijuana are not limited to genes involved in THC production, while the reported C. sativa and C. indica ancestries of marijuana strains only partially capture the main axes of marijuana’s genetic structure.

To evaluate the genetic structure of commonly cultivated Cannabis, we genotyped 81 marijuana and 43 hemp samples using genotyping-by-sequencing (GBS) [5]. The marijuana samples represent a broad cross section of modern commercial strains and landraces, while the hemp samples include diverse European and Asian accessions and modern varieties. Although we sampled a diverse collection of cannabis types in our study, access to samples is complicated by the fact that marijuana is an illicit drug and there are limited repositories of hemp germplasm in international seedbanks. In total, 14,031 SNPs were identified after applying quality and missingness filters. Principal components analysis (PCA) of both marijuana and hemp (Fig 1a) revealed clear genetic structure separating marijuana and hemp along the first principal component (PC1). This distinction was further supported using the fastSTRUCTURE algorithm [6] assuming K = 2 ancestral populations (Fig 1c). PCA and fastSTRUCTURE produced highly similar results: a sample’s position along PC1 was strongly correlated with its group membership according to fastSTRUCTURE at K = 2 (r2 = 0.98; p-value < 1 x 10−15).

We observe a putative C. indica marijuana strain from Pakistan that is genetically more similar to hemp than it is to other marijuana strains (Fig 1a). Similarly, the hemp sample CAN 37/97 clusters more closely with marijuana strains (Fig 1a). These outliers may be due to sample mix-up or their classification as hemp or marijuana may be incorrect. The sample of CAN 37/97 that we genotyped was from a Canadian hemp germplasm collection, which obtained this accession from the IPK Genebank (Gatersleben, Germany). The original source country is France but there is limited information to indicate the cultivation of CAN 37/97 as hemp. Alternatively, these samples may be true outliers and represent exceptional strains that are genetically unlike others in their group. Using the current data set, the unambiguous identification of a sample as either hemp or marijuana would be possible in the former case, but not in the latter. In any case, we find that the primary axis of genetic variation in Cannabis differentiates hemp from marijuana.

These results significantly expand our understanding of the evolution of marijuana and hemp lineages in Cannabis. Previous analyses have shown that marijuana and hemp differ in their capacity for cannabinoid biosynthesis, with marijuana possessing the BT allele coding for tetrahydrocannabinolic acid synthase and hemp typically possessing the BD allele for cannabidiolic acid synthase [7]. As well, transcriptome analysis of female flowers showed that cannabinoid pathway genes are significantly upregulated in marijuana compared to hemp, as expected from the very high THC levels in the former compared to the latter [3]. Our results indicate that the genetic differences between the two are distributed across the genome and are not restricted to loci involved in cannabinoid production. In addition, we find that levels of heterozygosity are higher in hemp than in marijuana (Fig 1b; Mann-Whitney U-test, p-value = 8.64 x 10−14), which suggests that hemp cultivars are derived from a broader genetic base than that of marijuana strains and/or that breeding among close relatives is more common in marijuana than in hemp.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4550350/

Attachments

( part 2 )

Although the taxonomic separation of the putative taxa C. sativa and C. indica remains controversial, a vernacular taxonomy that distinguishes between “Sativa” and “Indica” strains is widespread in the marijuana community. Sativa-type plants, tall with narrow leaves, are widely believed to produce marijuana with a stimulating, cerebral psychoactive effect while Indica-type plants, short with wide leaves, are reported to produce marijuana that is sedative and relaxing. We find that the genetic structure of marijuana is in partial agreement with strain-specific ancestry estimates obtained from various online sources (Fig 2, S2 Table). We observe a moderate correlation between the positions of marijuana strains along the first principal component (PC1) of Fig 2a and reported estimates of C. sativa ancestry (Fig 2c)(r2 = 0.36; p-value = 2.62 x 10−9). This relationship is also observed for the second principal component (PC2) of Fig 1a (r2 = 0.34; p-value = 1.21 x 10−8). This observation suggests that C. sativa and C. indica may represent distinguishable pools of genetic diversity [1] but that breeding has resulted in considerable admixture between the two. While there appears to be a genetic basis for the reported ancestry of many marijuana strains, in some cases the assignment of ancestry strongly disagrees with our genotype data. For example we found that Jamaican Lambs Bread (100% reported C. sativa) was nearly identical (IBS = 0.98) to a reported 100% C. indica strain from Afghanistan. Sample mix-up cannot be excluded as a potential reason for these discrepancies, but a similar level of misclassification was found in strains obtained from Dutch coffee shops based on chemical composition [10]. The inaccuracy of reported ancestry in marijuana likely stems from the predominantly clandestine nature of Cannabis growing and breeding over the past century. Recognizing this, marijuana strains sold for medical use are often referred to as Sativa or Indica “dominant” to describe their morphological characteristics and therapeutic effects [10]. Our results suggest that the reported ancestry of some of the most common marijuana strains only partially captures their true ancestry.

Although the taxonomic separation of the putative taxa C. sativa and C. indica remains controversial, a vernacular taxonomy that distinguishes between “Sativa” and “Indica” strains is widespread in the marijuana community. Sativa-type plants, tall with narrow leaves, are widely believed to produce marijuana with a stimulating, cerebral psychoactive effect while Indica-type plants, short with wide leaves, are reported to produce marijuana that is sedative and relaxing. We find that the genetic structure of marijuana is in partial agreement with strain-specific ancestry estimates obtained from various online sources (Fig 2, S2 Table). We observe a moderate correlation between the positions of marijuana strains along the first principal component (PC1) of Fig 2a and reported estimates of C. sativa ancestry (Fig 2c)(r2 = 0.36; p-value = 2.62 x 10−9). This relationship is also observed for the second principal component (PC2) of Fig 1a (r2 = 0.34; p-value = 1.21 x 10−8). This observation suggests that C. sativa and C. indica may represent distinguishable pools of genetic diversity [1] but that breeding has resulted in considerable admixture between the two. While there appears to be a genetic basis for the reported ancestry of many marijuana strains, in some cases the assignment of ancestry strongly disagrees with our genotype data. For example we found that Jamaican Lambs Bread (100% reported C. sativa) was nearly identical (IBS = 0.98) to a reported 100% C. indica strain from Afghanistan. Sample mix-up cannot be excluded as a potential reason for these discrepancies, but a similar level of misclassification was found in strains obtained from Dutch coffee shops based on chemical composition [10]. The inaccuracy of reported ancestry in marijuana likely stems from the predominantly clandestine nature of Cannabis growing and breeding over the past century. Recognizing this, marijuana strains sold for medical use are often referred to as Sativa or Indica “dominant” to describe their morphological characteristics and therapeutic effects [10]. Our results suggest that the reported ancestry of some of the most common marijuana strains only partially captures their true ancestry.

Attachments

December 14, 2017

“When I became Commissioner of Agriculture, I made a commitment to do everything I could to put Kentucky’s industrial hemp crop on the path to commercialization,” Quarles said. “In order for that to happen, Congress needs to pass a law to remove industrial hemp from the list of controlled substances.”

Commissioner Quarles cited a recent report from The Courier-Journal in which a spokesperson for the DEA stated that all consumable industrial hemp products were illegal. This remark followed a 2016 “Statement of Principles” on federal hemp policy issued by the DEA, the United States Department of Agriculture, and the Food and Drug Administration that attempted to restrict research of industrial hemp. When the 2016 memorandum was released, Commissioner Quarles sent a letter to the federal agencies outlining his strenuous objections to it.

Chief among the concerns raised by Commissioner Quarles was the decision by the federal agencies to redefine “industrial hemp” to include only historically proven applications (fiber and seed) while excluding other potential applications. The recent Courier-Journal report revealed a new and unwelcome development in the DEA’s position: that even historically proven consumable applications such as grain are illegal.

“It is important that these agencies understand that our farmers and processors have real concerns about how these opinions affect real people here in Kentucky. Mixed messages from Washington only serve to frighten folks who want to invest in our state,” Quarles said. “We need to push back against unresponsive agencies and encourage Congress to remove industrial hemp from the list of controlled substances.”

To that end, Commissioner Quarles sent a letter today to the Acting Administrator of the DEA to ask once again for clarification on the agency’s opinion and for a meeting in January to discuss the industrial hemp pilot program.

https://ocmonitor.com/2017/12/14/quarles-rejects-federal-overreach-into-ky-hemp-program/

“When I became Commissioner of Agriculture, I made a commitment to do everything I could to put Kentucky’s industrial hemp crop on the path to commercialization,” Quarles said. “In order for that to happen, Congress needs to pass a law to remove industrial hemp from the list of controlled substances.”

Commissioner Quarles cited a recent report from The Courier-Journal in which a spokesperson for the DEA stated that all consumable industrial hemp products were illegal. This remark followed a 2016 “Statement of Principles” on federal hemp policy issued by the DEA, the United States Department of Agriculture, and the Food and Drug Administration that attempted to restrict research of industrial hemp. When the 2016 memorandum was released, Commissioner Quarles sent a letter to the federal agencies outlining his strenuous objections to it.

Chief among the concerns raised by Commissioner Quarles was the decision by the federal agencies to redefine “industrial hemp” to include only historically proven applications (fiber and seed) while excluding other potential applications. The recent Courier-Journal report revealed a new and unwelcome development in the DEA’s position: that even historically proven consumable applications such as grain are illegal.

“It is important that these agencies understand that our farmers and processors have real concerns about how these opinions affect real people here in Kentucky. Mixed messages from Washington only serve to frighten folks who want to invest in our state,” Quarles said. “We need to push back against unresponsive agencies and encourage Congress to remove industrial hemp from the list of controlled substances.”

To that end, Commissioner Quarles sent a letter today to the Acting Administrator of the DEA to ask once again for clarification on the agency’s opinion and for a meeting in January to discuss the industrial hemp pilot program.

https://ocmonitor.com/2017/12/14/quarles-rejects-federal-overreach-into-ky-hemp-program/

Vaporizando192

Member

EU certified official reseller ? Who are they ?

EU certified official reseller ? Who are they ?

Interested to buy legally some seeds of Eu certified Hemp i wonder which ones are the official reseller for Europe ?

Thx

EU certified official reseller ? Who are they ?

Interested to buy legally some seeds of Eu certified Hemp i wonder which ones are the official reseller for Europe ?

Thx

Read first postInterested to buy legally some seeds of Eu certified Hemp i wonder which ones are the official reseller for Europe ?

Thx

PS just fixed the broken link you're looking for (THAT ON).

I altered/updated my info about Finola see posts #17, 18, 19, 20.

My basic thought while Finola does start flowering like an Auto, it does not keep flowering like almost all Autos, it is determinate for sure. Most Autos want to keep making flowers and never really truly finish. I hate that as much of the resin build up is the last few weeks of flowering, and Autos mostly keep making more flowering biomass, on and on until harvested. They do not seem to be as frosty with resin if they keep making biomass/flowers.

-SamS

My basic thought while Finola does start flowering like an Auto, it does not keep flowering like almost all Autos, it is determinate for sure. Most Autos want to keep making flowers and never really truly finish. I hate that as much of the resin build up is the last few weeks of flowering, and Autos mostly keep making more flowering biomass, on and on until harvested. They do not seem to be as frosty with resin if they keep making biomass/flowers.

-SamS

Last edited:

Page not found.

Most people don’t understand the truly diverse value of hemp (Cannabis sativa). Cultures have depended on this hardy plant for centuries for clothing, fabric, and paper. Today, it is also used for food, fuel, medicine, building materials, and plastics. Now the energy storage industry is starting to take notice, thanks to new Canadian research that shows supercapacitors with electrodes made from hemp-based carbon nanosheets outperform standard supercapacitors by nearly 200%.

Graphene, a carbon nanomaterial, is considered to be one of the best materials for supercapicitor electrodes. Graphene is, however, expensive to manufacture, costing as much as $2,000 per gram. Looking for a less-costly solution, researchers at the University of Alberta/National Institute for Nanotechnology (NINT) NRC, and Alberta Innovates-Technology Futures, led by chemical and materials engineering Professor David Mitlin, developed a process for converting fibrous hemp waste into a unique graphene-like nanomaterial that outperforms graphene. What’s more, it can be manufactured for less than $500 per ton. “Our work actually opens up a very cheap and mass-producible manufacturing method for graphene-quality material—something that has never been achieved before,” says Mitlin.

Activated carbons, templated carbons, carbon nanofibers, carbon nanotubes, and graphene have all been intensively studied as materials for supercapacitor electrodes. High manufacturing costs is one issue—another is that the power characteristics of many of these carbons are limited. This is a result of high microporosity, which increases ion transport limitations.

“It is becoming well understood that the key to achieving high power in porous electrodes is to reduce the ion transport limitations” says Mitlin. “Nanomaterials based on graphene and their hybrids have emerged as a new class of promising high-rate electrode candidates—they are, however, too expensive to manufacture compared to activated carbons derived from pyrolysis of agricultural wastes, or from the coking operations.”

Biomass, which mainly contains cellulose and lignin by-products, is widely utilized as a feedstock for producing activated carbons. Mitlin decided to test hemp bast fiber’s unique cellular structure to see if it could produce graphene-like carbon nanosheets.

Hemp fiber waste was pressure-cooked (hydrothermal synthesis) at 180 °C for 24 hours. The resulting carbonized material was treated with potassium hydroxide and then heated to temperatures as high as 800 °C, resulting in the formation of uniquely structured nanosheets. Testing of this material revealed that it discharged 49 kW of power per kg of material—nearly triple what standard commercial electrodes supply, 17 kW/kg.

https://www.asme.org/engineering-topics/articles/energy/hemp-carbon-makes-supercapacitors-superfast

Vaporizando192

Member

i read it but ur link does not work.

any other list of official resellers ? i am interested just in Hemp EU certified but seems so difficult to find proper info on them and even difficult to buy them

thx