Dab Strudel

Active member

The you can top flood both columns about half as long as you can one at a time, before reaching upper limits.

Rule Number 1. The limitation on how much and how fast you can flood a Mk V system, is the size of your lower catch container and recovery speed, versus the rate you are flooding.

You have to keep the violently bubbling pool of liquid away from the pump intake, so as not to aspirate liquid into the pump. I prefer to use a minimum of 6" clearance, and with highly enriched material, that can be cutting things short, as the full 12" tall chamber fills with cotton candy under vacuum.

How efficiently you are "top showering" a column, is a function of the diameter of the orifice the butane is flowing into the column from, vis a vis the diameter of the column.

A 1/4" to 3/8" orifice in the center of a 2 to 4" column will not wash the material immediately adjacent to the injection port, as thoroughly as that in the center and even the sides further down the column.

Gravity flows mostly take the path of least resistance, so don't wet the sides of the column, where there is more resistance to flow, as thoroughly as the easy path it finds through.

Besides the obvious issue of gas venting, another prime reason that I prefer to bottom flood and top rinse to glean the residuals.

What I miss in residuals from a thin film of the last wash, is small compared to what I miss top showering alone, without over washing.

If your bragging rights credits are for museum quality shatters and waxes, and you are not willing to give up yield, consider putting a tee at the bottom and use dual valves and collection pots to separate the wash for museum quality and that for medibles.

Certainly you can dump one column and flood another at the same time, as long as you obey rule Number 1.

Getting more pump has its limits, as does more surface area for boiling, because of falling pressure ratings in sanitary connections as they grow larger.

The long part of the process is recovery. Our best dual cycle run with a Mk VA2, was 2 hours and 11 minutes, about 12 minutes of that time was flood and rinse/dump even the dual 4" X 36" column.

If you cut that flood time 99%, it would still take a couple hours to run dual cycle runs. That is why I have personally elected to not compromise on my control of flooding, and focusing process improvement on faster recovery.

We cut cycle time by about a third using a DI/ISO heat exchanger, and expect to cut it further once the N2 is hooked up to that system.

I envisioned the dual columns on the Mk V design, as a way for a commercial operator to swap columns while running the other one, so as to never have to shut down.

It also gives them the option to load 5 to 7# of material at one time, so as to minimize how many times they have to attend to loading. All her owners describe her as an animal and a beast.

For smaller columns and speed, a manual Mk IV is faster, and a Mk IV design, built on a Mk V 12" base, would be faster yet.

Too little heavy to be horsing around all day without having the superstructure supported for most of us'n man childs or sister women, but with a cart it would be faster than a 10" Mk IV.

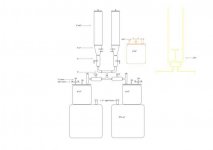

With your design and encouraging tips I've created the Megazord. With anymore thoughts I believe parts will be ordered monday! With all those ball valves I can have 2 10x12 spools, one for museum quality and one for mass quality, and a 6x6 spool attached for heating and medible quality. If both end up being the same quality the best I can say is I can do a whole days work before I open anything. I'm thinking the mass quality will be sitting in the tane as I will be over flowing on the museum quality one time only before switching to the mass quality pot. In between switching I will let it sit for a moment to be as productive as possible before dumping and a long shower. As the column heats up and is dumping in the 6x6 I will begin the right column. I believe with gas money vs delivery and spare parts I can pull this guy off for under 2500. Don't get me wrong, I haven't tallied up my pricing guide and I have one or two expensive pieces but if I don't hit 2k ill be surprised. Let me know if I can clarify anything up. The long 1/4" pipes going up are going to be cut off at a certain height and is going to be hosed to the 3" end caps, and if I can find them to be what I assume them to be, I will use 3"-2" cap reducers instead of 3" end caps where I will use ss wool and fit my coffee filters. And I just noticed I didn't put in my injection port, that is going to be on a cross instead of a T where the top two yellow 1/4" ball valves connect.

Heres two off the top for ya, should I leave my dump stem (where the 2" TirClamp T connects to the welded 6"x7" spool) or should I connect it to the 10" lid and remove it from the vicinity of the vac pumps 1" cross as well as take down the overall (unknown) height?

Second, I placed the dump stem strategically to be in the center of the 10"x12", how long should i make said dump stem? flush with the bottom of the 6"x7"? Thank you all in advance for your input