-

ICMag with help from Landrace Warden and The Vault is running a NEW contest in November! You can check it here. Prizes are seeds & forum premium access. Come join in!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LED FAQ) Building and DIY

- Thread starter Dion

- Start date

MrBreeze911

Active member

Thanks everybody, that saves me so much of a headache. I really appreciate it

SuperBadGrower

Active member

Are these recommendations still up to date? I am planning a 4x8 grow tent for both veg and flower and am planning on making my own diy grow lights.

Yeah at this point its' a price/convenience thing. LED makers were just so bad, nobody could come up with a way to do it right. In 2017 you could easily make something cheaper and better than any commercial led. Now they all have knobs and dimmers, external driver mounting, good coverage... If I ever need a new light in the future, I don't think I will DIY again. If it's your first setup and you are on a budget, maybe it's still cheaper to buy a Meanwell driver and hook up some strips.

xet

Active member

Even now there are still critically stupid issues with LED manufacturers. i am in contact with 20+ manufacturers in China/HK. Here is an example: How can one manufacturer produce a $12 200W LED while the other is producing a $40 200W LED? The $40 LED is using 99.99% gold wire and copper brackets and the $12 may as well be using pig iron.Yeah at this point its' a price/convenience thing. LED makers were just so bad, nobody could come up with a way to do it right. In 2017 you could easily make something cheaper and better than any commercial led. Now they all have knobs and dimmers, external driver mounting, good coverage... If I ever need a new light in the future, I don't think I will DIY again. If it's your first setup and you are on a budget, maybe it's still cheaper to buy a Meanwell driver and hook up some strips.

Also, meanwell, or whoever, as amazing as they are, power supplies are still a laughing joke of their potential.

R&D, servicing demand.. hyperinflation, erroneous regulation and import/export levvys, mining, all things getting in the way of innovation.

All that said it is still possible to DIY a high-end 600W LED for <$100.

Ca++

Well-known member

You will have to show us I think. It looks like a typo to me.it is still possible to DIY a high-end 600W LED for <$100.

Building has hidden costs. A 4x8 won't be earning you $75 a day, on the days you are waiting for parcels. I could order a light today for tomorrow, or spend today searching for parts, missing the post. $75 gone. Parts that will come from China. $350 - $1000 gone. You can literally loose the cost of the lights, because some cheap item took 2 weeks to arrive. Things often take 3 weeks. That is $1500 lost. This is before we have actually bought anything. 6 weeks isn't unusual.

Logistically, you could put your seeds in today, then order lights you know will arrive before you need them. However, if you buy parts then they might not arrive, so you can't do your seeds today. You are gambling that the cheap supplier won't put your item on a boat. Obviously if you are saving money before you can do the grow, then timescale takes second place to even getting one done. However, if you have the money already, there is no gain from waiting weeks.

Your mileage may vary.

SuperBadGrower

Active member

I'm curious how you envision building a high end 600W led for that cheap. Digikey's cheapest driver in that power range is $133. Maybe <$1/watt? Yes, but in 2022 only in USA and China

In terms of warranty it's better to build your own. Valid points raised above by xet... They will do anything to skimp on parts, that will never change

In terms of warranty it's better to build your own. Valid points raised above by xet... They will do anything to skimp on parts, that will never change

xet

Active member

I could use the same logic for sunlight and say all artificial light is losing. It's all relative.You will have to show us I think. It looks like a typo to me.

Building has hidden costs. A 4x8 won't be earning you $75 a day, on the days you are waiting for parcels. I could order a light today for tomorrow, or spend today searching for parts, missing the post. $75 gone. Parts that will come from China. $350 - $1000 gone. You can literally loose the cost of the lights, because some cheap item took 2 weeks to arrive. Things often take 3 weeks. That is $1500 lost. This is before we have actually bought anything. 6 weeks isn't unusual.

Logistically, you could put your seeds in today, then order lights you know will arrive before you need them. However, if you buy parts then they might not arrive, so you can't do your seeds today. You are gambling that the cheap supplier won't put your item on a boat. Obviously if you are saving money before you can do the grow, then timescale takes second place to even getting one done. However, if you have the money already, there is no gain from waiting weeks.

Your mileage may vary.

That would make a cool thread, the $100 600W LED.

xet

Active member

I was talking to a supplier yesterday about their $3 | 50W LED's (just the cob). Excellent power supplies too are still dirt cheap. I need to do a write-up.I'm curious how you envision building a high end 600W led for that cheap. Digikey's cheapest driver in that power range is $133. Maybe <$1/watt? Yes, but in 2022 only in USA and China

In terms of warranty it's better to build your own. Valid points raised above by xet... They will do anything to skimp on parts, that will never change

SuperBadGrower

Active member

Show us these excellent ~$20 driver with >95% or even >90% efficiency

The cheapest acceptable ~50W COB is $11.9, it's Citizen's CLU, and it is already crap compared to today's strips/bars/etc. which can give 25% more light per watt. This supplier sounds like they're selling you a pipe dream

The cheapest acceptable ~50W COB is $11.9, it's Citizen's CLU, and it is already crap compared to today's strips/bars/etc. which can give 25% more light per watt. This supplier sounds like they're selling you a pipe dream

xet

Active member

My 750W Meanwell Driver is only rated @ 92% efficiency.Show us these excellent ~$20 driver with >95% or even >90% efficiency

At least try to sound halfway intelligent.

SuperBadGrower

Active member

I'm simply asking you to show cheap drivers that would be considered "high end", with >95% or even >90% efficiency. No need to act like a kid about. Talk the talk, walk the walk... You come into a DIY thread claiming you can make a high end 600 watter for $100. Youre lucky that our reaction is one of skepticism instead of straight up laughter.

Ca++

Well-known member

There is a good market for smaller drivers. Lots are used in street lighting and architectural spots inside and out. All the big players like Osram, Philips and Sylvania are in the game. With the even cheaper brands making competing kit. All of which has to be properly made to be of use to proper manufacturers.

I tried about half a dozen $10 versions from China. I'm usually fine with stuff off Ali, but cheap LEDs are another matter. One driver was alright. An open framed device you could see was real. All the rest were half the wattage on the sticker. That wasn't the problem though. It was the noise. They blatted out my radio, no matter how much additional filtering I added. I had triple common mode chokes on the in and out, and still knew my neighbours radio was being effected.

There is cheap, and there is uselessly cheap. IIRC if was HGL came here with their new light with their own ballast, and refused to test it. The pictures showed it was a $5 design, and best we could get from the rep, was that they would change it in the future. They really will sell us any old crap if they can get away with it. The presence of approval stickers, usually just highlights their dishonesty.

An Osram optotronic 50w driver is $25 and I can't do any better. I pair them with the above mentioned shitizen clu on a $10 am2 cpu cooler. Making a $50 50w light. However the R&D took a while. All 3 of the major components were swapped over time. Noisy drivers. Poor chips. Heatsinks with better mounting options. I will never try and tap a blind 3mm hole again. Ever.

I tried about half a dozen $10 versions from China. I'm usually fine with stuff off Ali, but cheap LEDs are another matter. One driver was alright. An open framed device you could see was real. All the rest were half the wattage on the sticker. That wasn't the problem though. It was the noise. They blatted out my radio, no matter how much additional filtering I added. I had triple common mode chokes on the in and out, and still knew my neighbours radio was being effected.

There is cheap, and there is uselessly cheap. IIRC if was HGL came here with their new light with their own ballast, and refused to test it. The pictures showed it was a $5 design, and best we could get from the rep, was that they would change it in the future. They really will sell us any old crap if they can get away with it. The presence of approval stickers, usually just highlights their dishonesty.

An Osram optotronic 50w driver is $25 and I can't do any better. I pair them with the above mentioned shitizen clu on a $10 am2 cpu cooler. Making a $50 50w light. However the R&D took a while. All 3 of the major components were swapped over time. Noisy drivers. Poor chips. Heatsinks with better mounting options. I will never try and tap a blind 3mm hole again. Ever.

Three Berries

Active member

That Power supply worked great with the 36v LEDs. It had a 4v range so some dimming was available. Ran them almost three years straight at 66% load. This was some 7 years ago or so. Still got them if you want to make a deal.....

xet

Active member

I went and did some homework and this is what I learned.Personally...

If I was expecting to run 30A in my grow area I would be running 240v 30A three wire #10 w ground to a disconnect in a sub panel. And wire directly to a terminal strip inside a control box. If it's the typical one armed bandit gray box disconnect switch it has to be independent of the control panel. You could use a 240v 30A toggle switch as an on/off inside the panel.

that way you can be certain the mains to panel is to size and easily add on. 30A outlets are generally one plug jobs , bulky and and expensive.

This is a branch circuit.

The box in the middle with the blue wires is the sub-panel/control box/gray box disconnect. The Service-Entrance Conductors, the one on the right with my other household connects is where I start my 240v 30a three wire #10 w ground before going to the blue wire disconnect in the sub-panel.

Here is showing some more advanced branched circuitry work

This is the one-armed bandit that goes inside of the sub-panel.

Here is that one-armed bandit gray box with the 240v 30A toggle switch.

Am I understanding properly?

Wiring

#10 main -> #10 sub-panel -> #14 to wall socket > #14 to PSU > #10 to LED

I emailed Meanwell and they told me #16 would be fine for the input on 240v but since I will be running it about 30', #14 feels safer.

Now that covers 1 of my 708w cobs.

Suppose I run 2 of these 708w cobs - both running their own PSU whose max output is 27.8a?

xet

Active member

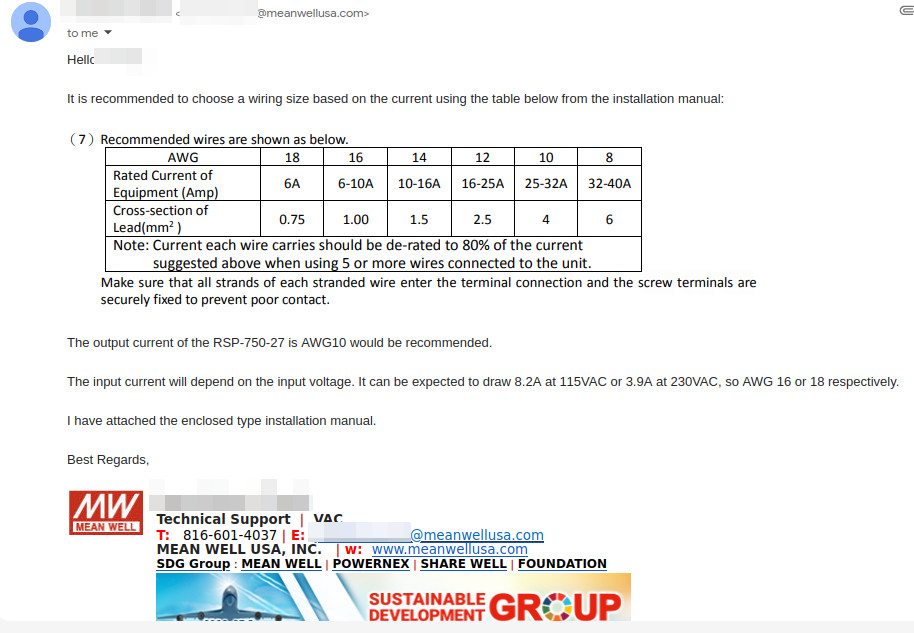

Here is the Meanwell tech email.

Is it a simple matter of addition, 10a + 10a = 20a for 2 PSU?

I am still wanting to understand how current amplification works.

I am wondering this:

If the input is 10amps and the output is 27.8amps then is the total draw on the entire circuit 27.8 amps back to the sub-panel or does the current amplification from 10a to 27.8 only occur at the PSU therefore the total draw at the sub-panel is only 10amps?

I realize the question sounds redundant but redundancy is being my best teacher in this new field. But I don't understand current amplification and I am definitely not finding the right search terms for literature on the topic. By redundant I mean 10amp input, 16AWG Input, what could be more explicit on what to use, but I am looking for the understanding of the mechanisms producing a 27.8a output and as far as I can tell it is something to do with transistors, collected current.

Is it a simple matter of addition, 10a + 10a = 20a for 2 PSU?

I am still wanting to understand how current amplification works.

I am wondering this:

If the input is 10amps and the output is 27.8amps then is the total draw on the entire circuit 27.8 amps back to the sub-panel or does the current amplification from 10a to 27.8 only occur at the PSU therefore the total draw at the sub-panel is only 10amps?

I realize the question sounds redundant but redundancy is being my best teacher in this new field. But I don't understand current amplification and I am definitely not finding the right search terms for literature on the topic. By redundant I mean 10amp input, 16AWG Input, what could be more explicit on what to use, but I am looking for the understanding of the mechanisms producing a 27.8a output and as far as I can tell it is something to do with transistors, collected current.

Last edited:

There is no amplification. There is transformation from AC to DC and from high voltage 110-240V to lower voltage (depending on led draw and circuit design). There is same amount of power, as power is not lost, only converted.

INPUT = X POWER, OUTPUT will be (X power - losses) as heat from PSU efficiency. You get 95%+ or whatever depending on psu rating in form of DC current and the rest as heat.

My opinion is you have a lot to learn before you should play with electricity.

INPUT = X POWER, OUTPUT will be (X power - losses) as heat from PSU efficiency. You get 95%+ or whatever depending on psu rating in form of DC current and the rest as heat.

My opinion is you have a lot to learn before you should play with electricity.

Looks like quite a mess.

The basics are as explosive said...input matters. Output has lower power than input because of losses.

Wire gauge should fit the input amperage, add one size for precaution.

If you have a specific setup to build, post it here so maybe we can help you stay alive

Cheers

The basics are as explosive said...input matters. Output has lower power than input because of losses.

Wire gauge should fit the input amperage, add one size for precaution.

If you have a specific setup to build, post it here so maybe we can help you stay alive

Cheers