Three Berries

Active member

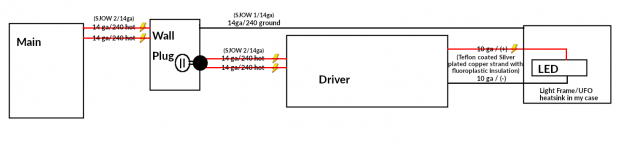

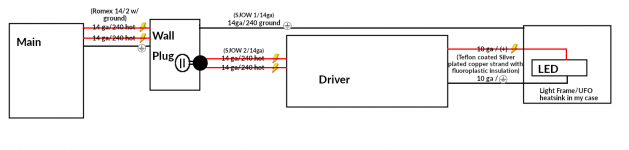

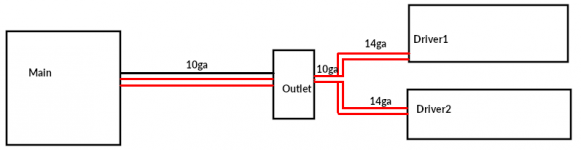

I'd just be getting 14 ga SOJW cord for the outlet to driver. It's only a 700 watt load. Typical 120v house wiring is 12g branching off to 14 ga. 15A or 20A.

Almost all plant LEDs are 100-250v input. They just swap the plugs for your country's flavor.

Almost all plant LEDs are 100-250v input. They just swap the plugs for your country's flavor.