TrueGangsta148

Member

When feeding sub-panels, you need to use SER cable. All grounded (neutrals) and grounding (grounds) conductors need to be isolated in a sub-panel. If you guys look at your main panel, you'll probably see both grounds and neutrals terminated to the same buss bar. Don't do this in a sub-panel.

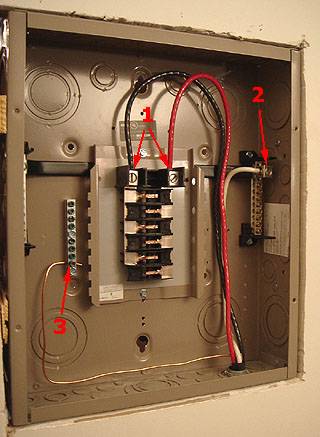

Here is a MLO panelboard (Main Lug Only sub-panel) fed with, what looks to be 6 or 8 gauge romex. If it's #6 CU romex, then you have to use no larger than a 60A double pole breaker in your main panel. If it's #8 CU romex, then no larger than a 40A double pole breaker in your main panel.

1. The ungrounded conductors (red and black) are connected to the top 2 main lugs which in turn feed the hot buss bars.

2. The grounded conductor (white) is connected to the large lug on the neutral buss bar. The neutral buss will be isolated from the frame of the panel. Notice this panelboard has 2 neutral buss, the other one is hiding to the left.

3. The grounding conductor (no sheathing) is connected to the ground buss. This will be directly fastened to the panel frame. Some panelboards don't come with a dedicated ground buss. You must purchase and install it separately if not. I also don't like the location of that ground buss. Too close to the hot and neutral buss. I would have put it down below.

Here's a close up of the isolated neutral buss:

Notice the bonding bar with the green screw. Remove this entirely. Some panelboards will come with a thin bonding strap, others will come with a long green grounding screw. It's to bond the neutral bus to the frame of the panel if you are using the panelboard as a main panel. In that case, you would loosen the screw, rotate the bar to the right and put it under one of the terminals on the neutral buss, then tighten down both screws. Don't do this on a sub-panel.

So, to connect the feeder cable in your main panel, attach your grounding wire first. This will more than likely get terminated to your neutral buss in the main panel as will the neutral wire of our feeder like so:

If your neutrals and grounds are separated in your main panel, this likely means you have an outside disconnect right below the meter. That means your main panel is actually a sub-panel!!! If that's the case, then you would tie the ground wire for your new sub-panel feed onto the isolated ground buss in your main panel.

Hope I didn't loose anyone there.But... If all your neutrals and grounds are terminated to the same buss bar in your main panel, both the neutral and ground of your sub-panel feed get terminated to your main panels neutral buss bar as the pic above shows.

so When i wired up my sub panel as described above, it throws the breaker on the main panel as soon as i try to turn it on. If i attach the included screw that grounds the neutral bus bar, then the sub panel and the circuits ran from it work. (I only tested the 120 outlets, not the 240) What does this mean? I have the breaker off at the main panel for now, till i get a definitive answer. I also have a friendly electrician coming over in the next 1 or 2 days for a different reason, but i'll have him take a gander at this as well.