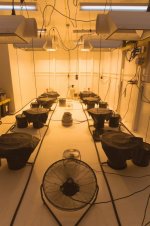

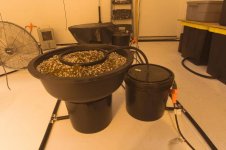

this thread is intended to show the "state of the art" ppk plumbing.

since i started on this journey more than seven years ago the basic operating principles have remained the same but we have all gone through many iterations of plumbing.

most of these, i now realize, were derived from our collective past hydroponic experiences.

but this device does not have the same plumbing needs as other hydro types and needs a unique approach.

we have had clogged lines and tailpieces. with overflows and drowned plants occasionally.

some of the plumbing schemes did not scale up well for larger rooms.

usually we have used large central pumps and hard pvc plumbing and were forced into all kinds of methods of equalizing volume of solution delivered and homogenizing solution ppm and ph so that the system reads the same no matter where you take a reading.

because this is slo-mo-hydro another approach is possible.

what i'm going to attempt to do in this thread is operate a 28 plant facility with plants in every stage of life, from new transplants to harvest, on one body of solution.

steering that solution and changing that solution when necessary by observing ppm and ph trends.

most hydro heads know the plant takes up nutrients selectively dependent upon it's stage of growth.

perhaps we feed a "balanced ratio" not so much for uptake but for the stability of the remaining solution.

if the ratio is really balanced and we have a large number of plants in all stages of life pulling on it simultaneously should the solution not remain stable?

i am using a perpetual scheme but in a larger facility with multiple rooms doing staggered unit grows and a vegetative room i think it would be much the same in regards to overall effect.

since i started on this journey more than seven years ago the basic operating principles have remained the same but we have all gone through many iterations of plumbing.

most of these, i now realize, were derived from our collective past hydroponic experiences.

but this device does not have the same plumbing needs as other hydro types and needs a unique approach.

we have had clogged lines and tailpieces. with overflows and drowned plants occasionally.

some of the plumbing schemes did not scale up well for larger rooms.

usually we have used large central pumps and hard pvc plumbing and were forced into all kinds of methods of equalizing volume of solution delivered and homogenizing solution ppm and ph so that the system reads the same no matter where you take a reading.

because this is slo-mo-hydro another approach is possible.

what i'm going to attempt to do in this thread is operate a 28 plant facility with plants in every stage of life, from new transplants to harvest, on one body of solution.

steering that solution and changing that solution when necessary by observing ppm and ph trends.

most hydro heads know the plant takes up nutrients selectively dependent upon it's stage of growth.

perhaps we feed a "balanced ratio" not so much for uptake but for the stability of the remaining solution.

if the ratio is really balanced and we have a large number of plants in all stages of life pulling on it simultaneously should the solution not remain stable?

i am using a perpetual scheme but in a larger facility with multiple rooms doing staggered unit grows and a vegetative room i think it would be much the same in regards to overall effect.