POTENCY

YIELD

DURATION

CHEMO-TYPE COMPLEXITY

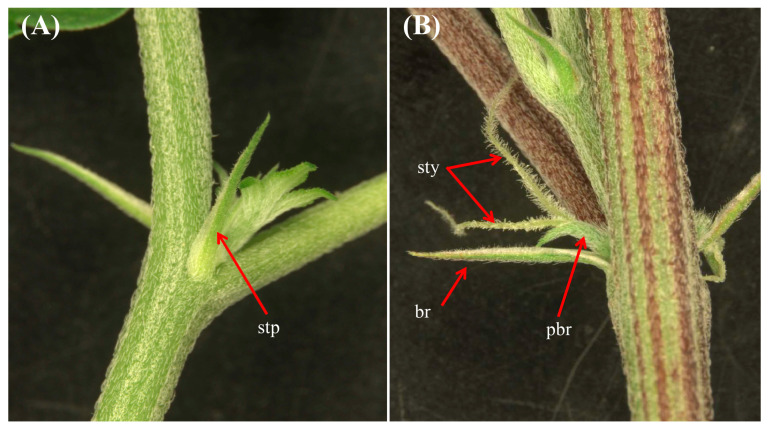

FLOWER MATURITY TYPE ALT PHYLLOTAXY

INDOOR VS OUTDOOR MORPHOLOGY

PERFECTLY IMPERFECT

NOVELTY

WILD

YIELD

DURATION

CHEMO-TYPE COMPLEXITY

FLOWER MATURITY TYPE ALT PHYLLOTAXY

INDOOR VS OUTDOOR MORPHOLOGY

PERFECTLY IMPERFECT

NOVELTY

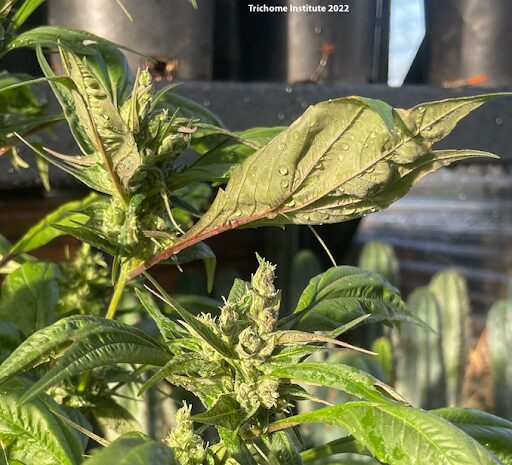

WILD

Pin It

Pin It