-

ICMag with help from Phlizon, Landrace Warden and The Vault is running a NEW contest for Christmas! You can check it here. Prizes are: full spectrum led light, seeds & forum premium access. Come join in!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ReikoX's Workshop Rebuild 2020

- Thread starter ReikoX

- Start date

ReikoX

Knight of the BlackSvn

With the old flooring completely removed, I decided to get the walls prepped for paint. As you can see, I was getting some mold buildup behind my cabinets.

First step was to spray everything down with vinigar and let it set for an hour. I ran some errands and when I came back my house smelled like a salad. After that I added about 8 tablespoons of baking soda to a half a gallon of water and used that to scrub down the walls.

First step was to spray everything down with vinigar and let it set for an hour. I ran some errands and when I came back my house smelled like a salad. After that I added about 8 tablespoons of baking soda to a half a gallon of water and used that to scrub down the walls.

ReikoX

Knight of the BlackSvn

I'm pretty sure I won't be needing a land line in the grow room anymore. So I filled the hole with some hardware cloth and taped over it.

You can see the hole is filled now, along with any other random nail holes that were in the walls. I also put a bit of a texture over the bare sheetrock. Most of that will be covered with the cabinets anyway. A little sanding tomorrow and it should be ready for a coat of KillZ.

And I need to decide what I'm going to do with the ceiling. My intuition says sheetrock it, I'm sure the humidity isnt going to play well with these ceiling tiles. What do you all think?

You can see the hole is filled now, along with any other random nail holes that were in the walls. I also put a bit of a texture over the bare sheetrock. Most of that will be covered with the cabinets anyway. A little sanding tomorrow and it should be ready for a coat of KillZ.

And I need to decide what I'm going to do with the ceiling. My intuition says sheetrock it, I'm sure the humidity isnt going to play well with these ceiling tiles. What do you all think?

Trash the tiles and install sheet rock, my two cents.

OG_NoMan

Not Veteran

Little more progress was made today. Got the ceiling tiles all down.

View Image

Since I'm going to be putting up sheetrock I don't need all these strips either.

View Image

Looks like I need to do another dump run.

View Image

Put those strips back up! They are called strapping and they are put up every 4` and you attach your drywall to it. What it does is isolates the movement in your floor joists above you so that your new drywall ceiling doesnt crack at the seems from movement. If I was you I would also put poly plastic up before hanging the drywall to keep vapor(moisture) out of the ceiling from the grow space. Good luck and love the progress

ReikoX

Knight of the BlackSvn

Today I cleaned up the ceiling tiles and the furring strips. Then I swept up all the nails and such. Finally I put a few coats of exterior primer/sealer on the walls. Painting is a lot easier when you dont have to worry about dripping paint on the floors. I always hated the yellow color in there.

I painted the shelf under the window and the window sill as well. This was the only part where I needed an edging brush.

I painted the shelf under the window and the window sill as well. This was the only part where I needed an edging brush.

I would go with epoxy floor coating. I used it in my old grow shed, worked well.

ReikoX

Knight of the BlackSvn

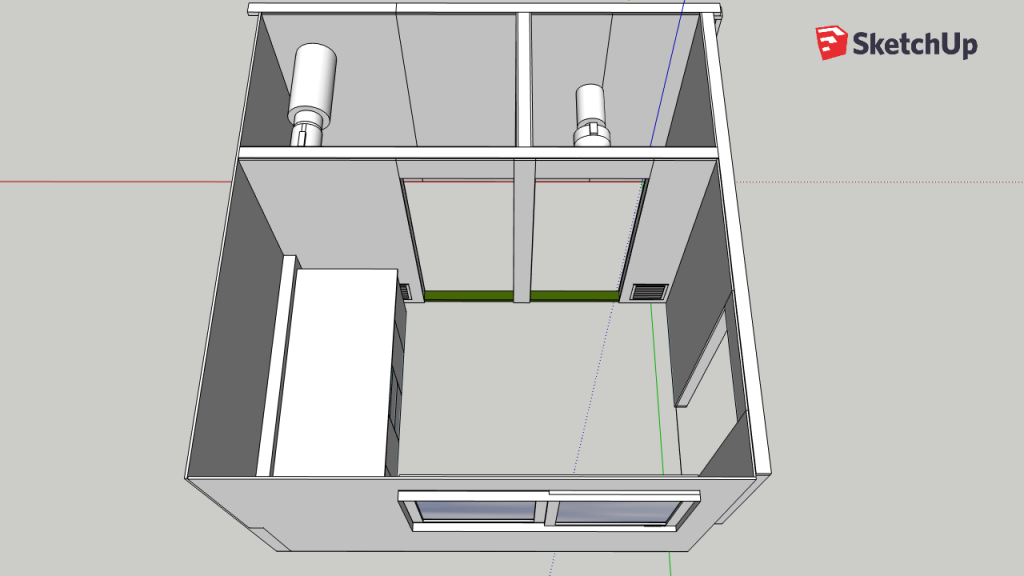

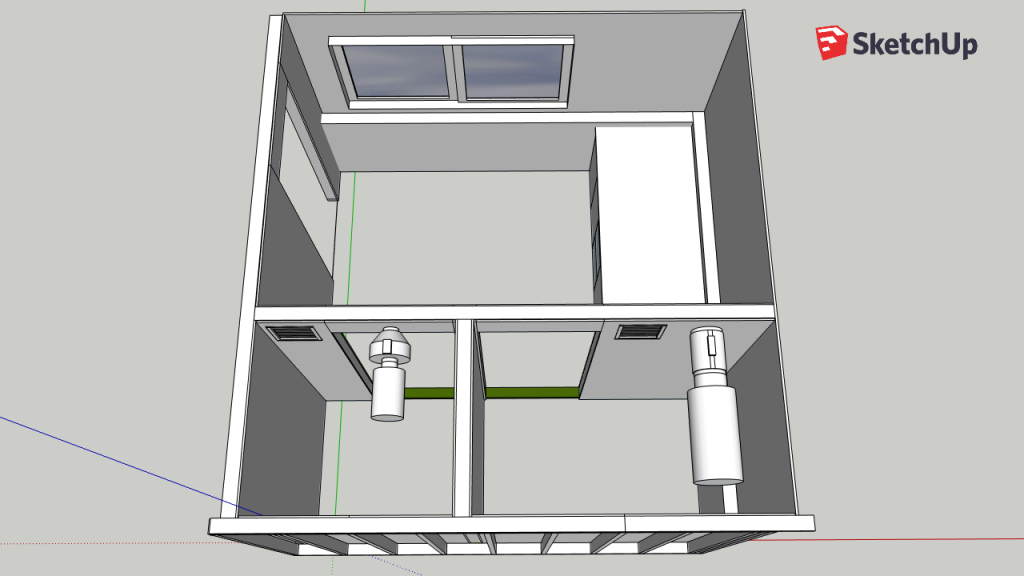

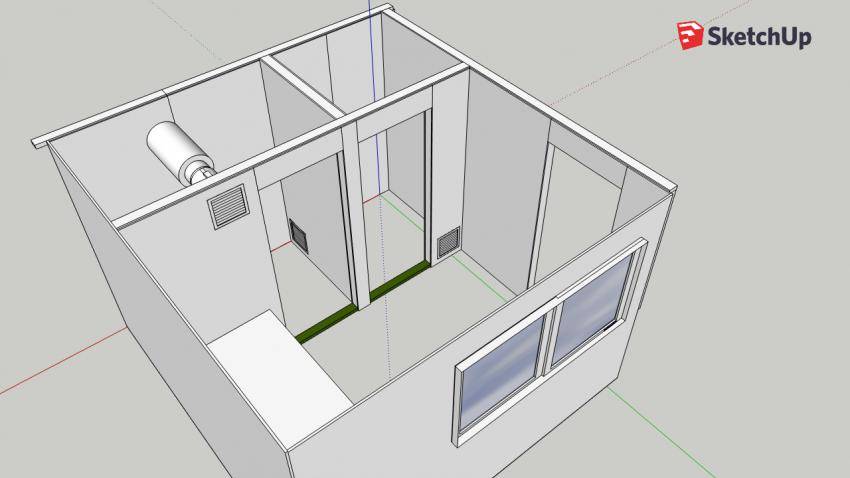

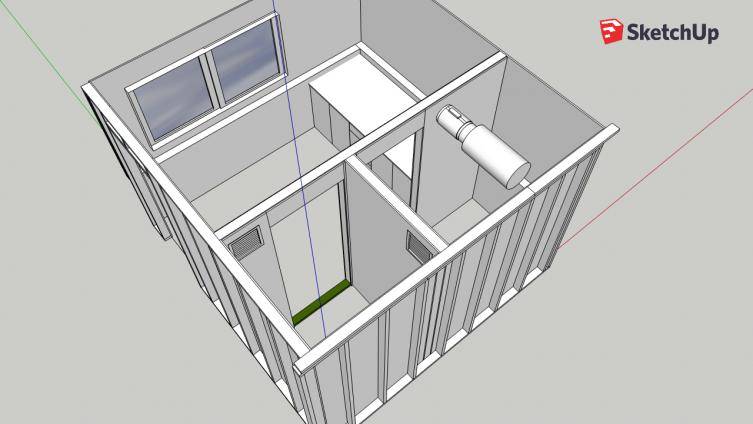

I've been debating between pulling through the veg room or having separate ventilation systems for each side. As it is, the workbench is going to be a very tight fit, and with a separate intake for each, the workbench would block the intake for flower. Thoughts or suggestions?

separate intake and exhaust for veg and flower (front)

separate intake and exhaust for veg and flower (back)

shared intake and exhaust for veg and flower (front)

shared intake and exhaust for veg and flower (back)

separate intake and exhaust for veg and flower (front)

separate intake and exhaust for veg and flower (back)

shared intake and exhaust for veg and flower (front)

shared intake and exhaust for veg and flower (back)

ReikoX

Knight of the BlackSvn

Pros:

On a small scale, it helps increase humidity in the flower room (I live in an arid climate), helps keep night time temps up, and uses fewer parts so it is cheaper.

Cons:

Not as much control over the veg room, potential for light leaks between rooms, and doesn't work when the flowering room door is open.

On a small scale, it helps increase humidity in the flower room (I live in an arid climate), helps keep night time temps up, and uses fewer parts so it is cheaper.

Cons:

Not as much control over the veg room, potential for light leaks between rooms, and doesn't work when the flowering room door is open.

ReikoX

Knight of the BlackSvn

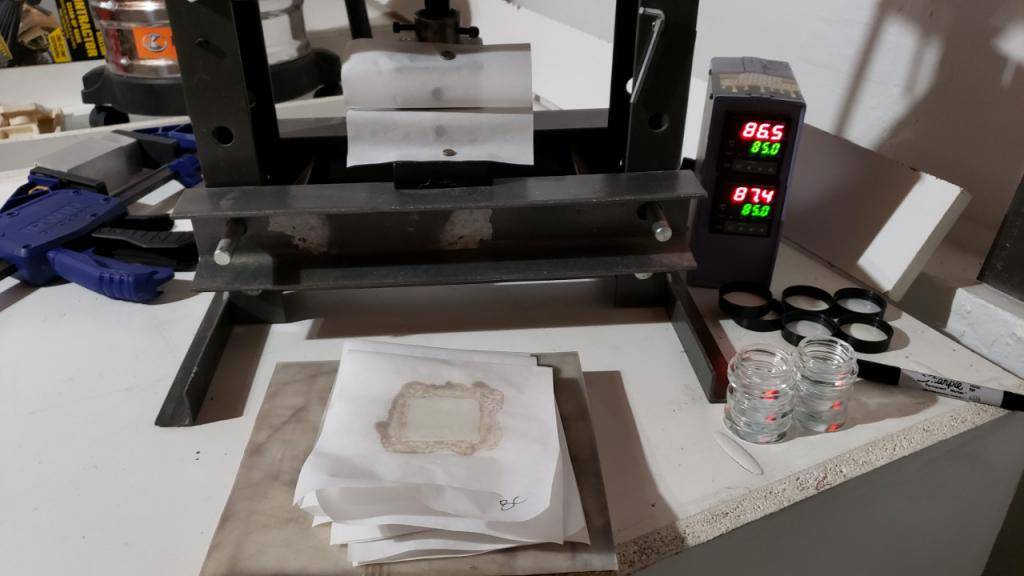

Dispite my workshop being under construction, I kept my press accessible. Today I decided I would press some rosin for my brother's birthday.

About 45 minutes later, I have a nice pile of parchment to collect.

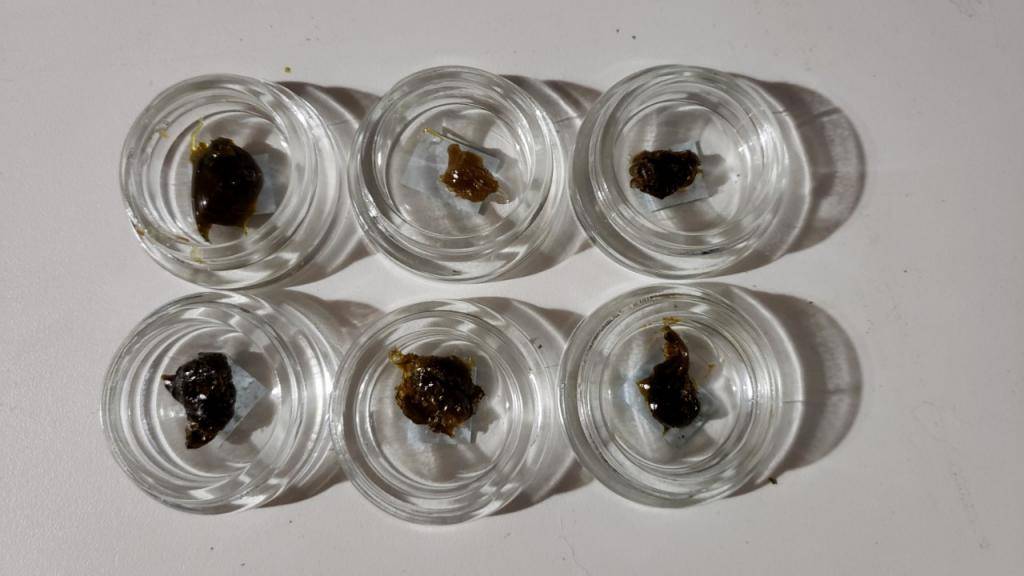

A variable cornucopia of flavors, consistencies, and yields.

]

]

About 45 minutes later, I have a nice pile of parchment to collect.

A variable cornucopia of flavors, consistencies, and yields.

ReikoX

Knight of the BlackSvn

So after some discussions, some thoughts, and some more modeling I think I am getting close to finished with the ventilation. I found some 12" x 24" darkroom louvers that I can put in the doors. I also decided to use separate fans for each side, I'm afraid I wont be able to control the environment otherwise. In this model I went with a Cloudline T8 for flower and a Cloudline T6 for veg. The size difference between the fans isn't that dramatic, thought the filters are a bit bigger.

Hey ReikoX,

I hope you don't mind if I ask a completely unrelated question.

If I remember correctly, you ran some mephisto autos under the leds. I have some that are 2 weeks under t-5s, about to go under some quantum boards. How strong do you think I should feed?

Thanks

I hope you don't mind if I ask a completely unrelated question.

If I remember correctly, you ran some mephisto autos under the leds. I have some that are 2 weeks under t-5s, about to go under some quantum boards. How strong do you think I should feed?

Thanks

ReikoX

Knight of the BlackSvn

Yesterday I went to the hardware store and got the lumber to frame the walls. I got treated lumber for the bottom against the concrete. I had to buy 12' pieces for the long wall because it was 124.5", just 4.5" short of a 10'.

First thing that I did was smoke a bowl. Then I got to work on my cut list. My grandpa always taught me to measure twice and cut once.

Once everything was cut, I begann assembly. This would have been a lot easier if I could have taken the two ends of the workbench out. I had to move them around to get all the nails in.

The top piece is 4.5" longer than the bottom because the cement sticks out. This required some juggling to lift the wall above it and nail the top piece on it. Finally got the wall up, it was a little tight in one spot, so I got a bigger hammer! I got it up and level. Then took out my tape measure and realized the bottom had moved! Pulled the nails and got it right the second time.

First thing that I did was smoke a bowl. Then I got to work on my cut list. My grandpa always taught me to measure twice and cut once.

Once everything was cut, I begann assembly. This would have been a lot easier if I could have taken the two ends of the workbench out. I had to move them around to get all the nails in.

The top piece is 4.5" longer than the bottom because the cement sticks out. This required some juggling to lift the wall above it and nail the top piece on it. Finally got the wall up, it was a little tight in one spot, so I got a bigger hammer! I got it up and level. Then took out my tape measure and realized the bottom had moved! Pulled the nails and got it right the second time.