LED FAQ) Building and DIY

- Thread starter Thread starter Dion

- Start date Start date

Dion

Active member

1 of the strips

They look nice

How much did you pay?

What are the specs?

Thanks for sharing

Thanks Dion, was interested in your lights too, but took chance on these . Mainly for quick US shipping. Was about $550 each light kit delivered . 10 strips of 2700-6500 mix of 30lh and b and then 4- 3500k strips .

All hardware , and a hlg 600 driver.

I didn’t want to mess with shipping from China yet, but might consider a Mejui or Kingbrite next time. I do like DIY just have little time to finish all the projects.

I think it will be quite a badass light when done though.

All hardware , and a hlg 600 driver.

I didn’t want to mess with shipping from China yet, but might consider a Mejui or Kingbrite next time. I do like DIY just have little time to finish all the projects.

I think it will be quite a badass light when done though.

Dion

Active member

Thanks Dion, was interested in your lights too, but took chance on these . Mainly for quick US shipping. Was about $550 each light kit delivered . 10 strips of 2700-6500 mix of 30lh and b and then 4- 3500k strips .

All hardware , and a hlg 600 driver.

I didn’t want to mess with shipping from China yet, but might consider a Mejui or Kingbrite next time. I do like DIY just have little time to finish all the projects.

I think it will be quite a badass light when done though.

To be fair I'm not really selling lights yet

I bought some stock and have been using it to do market research before making an actual moove

As I said earlier I've been happy to sell at cost price to forum members

My eBay store is just for collecting data

But you didn't tell us about ur lights, share the specs mate?

We love a bit of led porn in this thread

:yay:

packsmen

New member

Thank you for sharing this full guide about the LED light bulb building. I find your statistic and specifics really interesting and detailed, I'm not planning to build my own led light bulbs or smart strip lights, but this information will help me to choose the proper LED lights to ensure that I will install the proper lighting inside and outside of my house. I'm thinking of setting up the smart house by setting all my lighting inside of my house with smart led strips and smart LED bulbs.

xet

Active member

My cob manufacturer helped me choose my driver. I have a 700w cob and a 750w driver. How do I choose a wire size? Does it depend on if I use 240v or 120v plugin? I think 12 gauge is all I need for 120 but maybe it is also good for 240? Or maybe I Need 8 gauge for 240? Any help is appreciated

Three Berries

Active member

Generally 240V uses half the amps of 120V. And DC rating would only be on DC voltage output wires. Almost all wire rating charts like below also consider the wire inside conduit. Exposed to the air they will have a higher rating.

meters.co.uk

meters.co.uk

American Wire Gauge (AWG) Cable / Conductor Sizes - Meters UK

Need to know the AWG cable size for UK Attached is a chart detailing the description of each conductor property, including current, capacity, resistance,etc

xet

Active member

My driver is a Meanwell RSP 750-27 with an Output current of 27.8a and DC Output Voltage of 27 volts.Check your driver output current and get at least one step thicker wires than recommended. 700W is really high for one cob, what type is it? Maybe heat could be a problem...

Cheers

I will be wiring two of these cobs each with their own Driver.

I have a massive UFO heatsink to put them on and will have some big computer fans on top of the UFO fins just to be safe.

I had the cob custom manufactured. It is slightly north of 700W at 708W.

According to the wire gauge does this mean the 27.8a @ 240v is reduced to half of 27.8a @ ~13.9a and the wire chart for 15a means 10# will suit my needs? So 10/2 to the cob and 10/3 to the wall?

The amperage changes only before entering the driver. The input wires to the driver could be thinner at 240 volts than 120V, cause less current is needed at higher voltage to obtain same power. The DC side stays the same.

#10 would be ok for a dc circuit lenght of up to 10 ft when 3% loss is acceptable.

#10 would be ok for a dc circuit lenght of up to 10 ft when 3% loss is acceptable.

xet

Active member

( 240V wall plug ) + ( input wires from wall to 27.8a driver 7/3 ) + (output wires exiting driver to cob bc 240V will be reduced to half at 14A so 10/2 for +/- on the cob).The amperage changes only before entering the driver. The input wires to the driver could be thinner at 240 volts than 120V, cause less current is needed at higher voltage to obtain same power. The DC side stays the same.

I am so bad at understanding electricity. I had a really cool cob made that we will all enjoy to see in action. Thank you for the help.

Three Berries

Active member

No the 240v amperage being half the 120v is on the input side. But US 240V is two 120v, 180degrees out of phase cycling 120v+/120v- 60 times a second. I don't think that is how the EU is. So all your load amps are on one wire.

As an example I can wire my well pump for 120v or 240v. On 120v it draws 15A, on 240V it draws 8A, but total wattage is the same.

You still need wire for 30A on the output side. Generally the voltage rating of wire is based on where it is being used, conduit or open air, and then the type of insulation as per it's temp rating.

If you look at automotive wiring specs they are usually higher rated amp wise. Because they are single conductors in open air at a lower voltage.

And then you have to take into consideration the total length of the wire.

As an example I can wire my well pump for 120v or 240v. On 120v it draws 15A, on 240V it draws 8A, but total wattage is the same.

You still need wire for 30A on the output side. Generally the voltage rating of wire is based on where it is being used, conduit or open air, and then the type of insulation as per it's temp rating.

If you look at automotive wiring specs they are usually higher rated amp wise. Because they are single conductors in open air at a lower voltage.

And then you have to take into consideration the total length of the wire.

xet

Active member

The single 700W cob idea feels very interesting and a bit scary

Could you share some more infos about it, like specs and pics?

Cheers

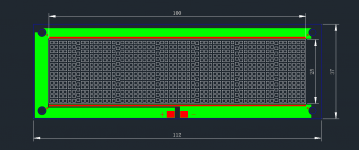

IT is only about 3.5" x 1.5".

Here is the schematic. I will grab some photos and the proper specs in a bit.

Attachments

xet

Active member

7/3 input, 10/2 outputNo the 240v amperage being half the 120v is on the input side. But US 240V is two 120v, 180degrees out of phase cycling 120v+/120v- 60 times a second. I don't think that is how the EU is. So all your load amps are on one wire.

As an example I can wire my well pump for 120v or 240v. On 120v it draws 15A, on 240V it draws 8A, but total wattage is the same.

You still need wire for 30A on the output side. Generally the voltage rating of wire is based on where it is being used, conduit or open air, and then the type of insulation as per it's temp rating.

If you look at automotive wiring specs they are usually higher rated amp wise. Because they are single conductors in open air at a lower voltage.

And then you have to take into consideration the total length of the wire.

Or is it easier to keep it 120V and use 7# all the way?

I was thinking because this cob is so "high performance" per se that 240V may treat the system, including the driver, better over the length of it's life as well as providing a more nascent flow of photons like during the case of dimming and running at 100%. Maybe that theoretical stuff does not matter.

xet

Active member

Do you see what I mean I might electrocute myself without your helpNothing will be reduced to half on the DC side!

Use this on the DC side. Keep in mind you count both the run to and back, so 10 feet circuit is basically 5 feetaway at most.

View attachment 18717560

Three Berries

Active member

Think like this with the different voltages. Amps in are all the same when looked at the end result of watts out.

Volts x Amps=Watts, generally

Volts x Amps=Watts, generally