-

ICMag with help from Landrace Warden and The Vault is running a NEW contest in November! You can check it here. Prizes are seeds & forum premium access. Come join in!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

V

vhGhost

wow the ebb/flow of my dreams

CarpeNoctem

Member

BlindDate said:One dangerous, scary, ghetto setup for sure. When they start to bring out the silicone sealant, it's time to run.

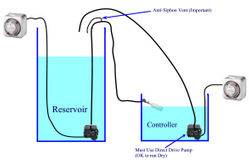

You all realize of course that you can do the exact same thing with

2 Beckett Pond pumps

2 simple timers (like Intermatic or those $7 mechanical ones)

1 mechanical float valve (mounted in the controler bucket)

Like This:

Place one pond pump in the res and plug it into a on/off timer (this one pumps nutes through a float valve mounted in the controller bucket). Place the other pond pump in the controler bucket also on an on/off timer (this one simply pumps nutes back to the res).

Program your timers so that they alternate and leave them on long enough to ensure that they complete the fill/drain cycle. Add an extra 5 minutes to be sure, it does not matter. I recommend the Beckett direct drive pumps rather than magnetic dives because they can run dry with no problem (like when the one inside the conroller bucket empties).

And there you have it. Much Much more reliable, no funky ghetto wiring, no relays, no construction projects. Doooh!!!

Any questions?

I'm stoned so I can't follow what you wrote here, but when I'm straight I'll take a look at it.

blinddate wrote...

One dangerous, scary, ghetto setup for sure. When they start to bring out the silicone sealant, it's time to run.

Excuse me blinddate, but this isnt your thread to be hyjacking, and furthermore, this device described in this thread is an excellent copy of the multiflow system controller, which does work flawlessly.

There is really nothing "scary, dangerous or Ghetto" about it.

btw, silicone is used in many electronics applications for waterproofing, mounting, isolating etc, and works the trick just fine imho.

Last edited:

10K.....True, his system will work, but as I stated, all those relays and electronic float valves are completely unnessessary. My post was not an attemp to "hijack" but to point out a better method applied to the same system. Isn't that what we are here for?

Regarding silicone: Having to seal via silicone should always be avoided. Silicone sealant is Micky Mouse. Bulkhead fittings and Uniseals give a positive mechanical seal. In this sport, leaks can be disasterous, especially if security is involved..

Regarding silicone: Having to seal via silicone should always be avoided. Silicone sealant is Micky Mouse. Bulkhead fittings and Uniseals give a positive mechanical seal. In this sport, leaks can be disasterous, especially if security is involved..

Last edited:

10K.....True, his system will work, but as I stated, all those relays and electronic float valves are completely unnessessary. My post was not an attemp to "hijack" but to point out a better method applied to the same system. Isn't that what we are here for?

OK, maybe my comment about hyjacking was a little too strong, but whether or not your method is "Better" or "more reliable" is VERY questionable, and a matter of personal opinion. I dont see why your alternative method would give you reason to ridicule in this thread, the multiflow controller design which uses dependable float switches instead of your suggested mechanical float valve. It's NOT "mickey mouse, ghetto or dangerous" in any way afaict.

However, I DO see a possible problem already with the alternative system you described, where the line running from the reservoir barrel to a mechanical float valve would result in a siphon being initiated in the res to controller float valve line, which would continue to feed the controller bucket every time the valve opened from the return pumping the controller below the float closed position. Thus keeping the controller bucket, and the entire crop flooded, regardless of whether or not the supply pump is running.

All the turned off supply pump will do in your design, is slow down the siphon action, but it will not stop it. In this regard, the krypto design uses a float switch to turn off the res pump, which allows the res to controller line to be routed in such a way that a siphon couldnt continue after the pump shuts off.

Regarding silicone: Having to seal via silicone should always be avoided. Silicone sealant is Micky Mouse. Bulkhead fittings and Uniseals give a positive mechanical seal. In this sport, leaks can be disasterous, especially if security is involved.

RTV Silicone is used by several major industrial electronics "mickey mouse" concerns like GM, Chrysler, MSD, NASA (the list goes on to infinity) as an effective seal against fluids entering electronics assemblies, machines and black boxes. It works the charm for holding glass aquariums together and leak free under tremendous pressures exerted.

Anyway, if I were to use your design, I'd probably choose a float switch and route the supply pipe so a siphon couldnt possibly happen. Maybe a seperate thread is in order for your design BlindDate ?

10K...To avoid the siphoning effect all you have to do is provide a vent tube at the highest point in the line. That would probably be as the tube goes over the top of the reservoir. Use a "T" fitting and extend a vertical tube up a few feet or bend it back into the reservoir.However, I DO see a possible problem already with the alternative system you described, where the line running from the reservoir barrel to a mechanical float valve would result in a siphon being initiated in the res to controller float valve line, which would continue to feed the controller bucket every time the valve opened from the return pumping the controller below the float closed position. Thus keeping the controller bucket, and the entire crop flooded, regardless of whether or not the supply pump is running.

Like This:

I did not mention this in my post because Krypto already addressed it using small 90 Degree barbs, although he did not explain why it was nessesary.

Krypto Says

VERY IMPORTANT!

Notice the two small 90 barbs that were pushed into the fill and drain lines.

These are very important using this system.

Locate them on the line where they will be kept above the water level when your res is full.

OK, OK already,,yes, silicone has its uses. The problem that I have is that most all containers that we use in these systems are made of Polyethylene. NOTHING sticks to Polyethylene.

Polypropylene and polyethylene are called "low energy" or "non-stick" plastics. This group includes Teflon (or polytetrafluoroethylene). The basically inert or inactive molecular structure of PP and PE is described as a "low energy state". Despite their widespread usefulness, "low energy" plastics have a quality that can make them hard to work with - they are difficult to seal or bond using commonly available sealant adhesives. Cyanoacrylate, epoxy, polyurethane, silicone (RTV for example), and most acrylic adhesives do not stick to polypropylene and polyethylene.

But if you absolutely must try bonding on Polyethylene, sweep the surface with a propane blow torch 4-5 times. This will make a positive charged surface and enhance the electron sharing with the silicone. Good Luck!

Last edited:

G

Guest

Very nice work Krypto. I use tables but i am alway looking for new ways to grow.

K+ lol

MOD

K+ lol

MOD

G

Guest

Didn't see a total price on building one of these units. Anyone know what the total cost of builing one of these units from buying all the parts? Just wanting to know how cost of price it is. To buying one of the controller's outright. I'm in the middle of building a bucket system and i'm thinking about building a controller also, but if it's going to be close to buying one. Then I'll just buy one, but if i'm going to save some money, then it's worth it to me. Glad to see this thread is still around

Just awesome

Just awesome

if i remember correctly BG, its i bit less than half than that of a store bought unit maybe even less than that , dont remember for sure.

i think its like a third the cost actually.

good mornin mr Garden Pimp, how are ya my brotha?

goddang good to see ya!

peace and a biggass bowl of cheerios

bonz

i think its like a third the cost actually.

good mornin mr Garden Pimp, how are ya my brotha?

goddang good to see ya!

peace and a biggass bowl of cheerios

bonz

G

Guest

Thanks Bonzo, I'm going to read through the thread again and do some cheaping. Been sick with a cold and this will be a good little project for me this weekend. Tracking down all the prices. Looks like i'm going to be building my own unit. That's alot of money saved for sure. Well worth it if you ask me.

Thanks again Bonzo

Thanks again Bonzo

Holy Shit Batman !

jeje sorry, just had too. An exceptional job, awesome pics...and all the time youve take'n into organize'n your posts and loading your pics, just incredible. Only right to give thanks for such a great job. Gona tag along and enojy the rest.

here in CR wher I live thise would be conected to a computer battery....as power goes out all too often !

Blessed.

Chaman

jeje sorry, just had too. An exceptional job, awesome pics...and all the time youve take'n into organize'n your posts and loading your pics, just incredible. Only right to give thanks for such a great job. Gona tag along and enojy the rest.

here in CR wher I live thise would be conected to a computer battery....as power goes out all too often !

Blessed.

Chaman

G

Guest

QC, Boy i haven't heard that term in along time. Roger that SGT, looks to be Golden. Sure doesn't look like the old soup sandwich term. Nice job, I'm in the middle of ordering all the parts. Should be doing my own term on building a complete system in about a week. Would love to use this schematic on my thread. If you don't mind?

Take care,

Ranger's Lead the Way

One Shot, One Kill

Airborne

You get the idea, lol

Take care,

Ranger's Lead the Way

One Shot, One Kill

Airborne

You get the idea, lol

Sgt. Stedenko authorizes all to use the schematic as they wish.

Sgt. Stedenko takes no responsibility for flooded basements, pissed spouses, etc.

That is all.

Sgt. Stedenko takes no responsibility for flooded basements, pissed spouses, etc.

That is all.

Last edited:

G

Guest

Well, I got some of the first parts to show up. I got the "Black Box", lol i like that name for the box, and a 9 foot 15amp 300 watt power cord. I really like this box alot, because it has a metal back plate and the rest of it is plastic. Cost to my house for both with shipping was 20.00 bucks. I also picked up a 55 gal open top drum that was used for pepper's. Got it at local feed store for 20.00 bucks plus tax. I should be getting my float switched and timer anytime soon. I'm going to do my own thread on construction of the controller with some changes of my own. I think more thread will make it easyer for others to build these units. Thank you everyone for your help and links. Love this thread and all the feedback.

Take care

Take care

G

Guest

Well, got my float sensor's in today and the rest of my stuff shoule be in tomorrow and Wed. I'll make sure to link my thread here for all to follow. I want to thank everyone for their info and help. I can't believe how much cheaper these units are compaired to buying one. lololol.

Thanks everyone,

BG

Thanks everyone,

BG