acespicoli

Well-known member

Mature flowers are characterized by apparent lack of unstalked glandular trichomes, as glandular trichomes have matured to the stalked stage (Livingston et al., 2019), and with more than 80% of pistils turning from white/green to brown.

Using correct spectrum light to check for mature stalked gland harvest time as outlined in DOI link above

- DOI: 10.1111/tpj.14516

Using correct spectrum light to check for mature stalked gland harvest time as outlined in DOI link above

Last edited:

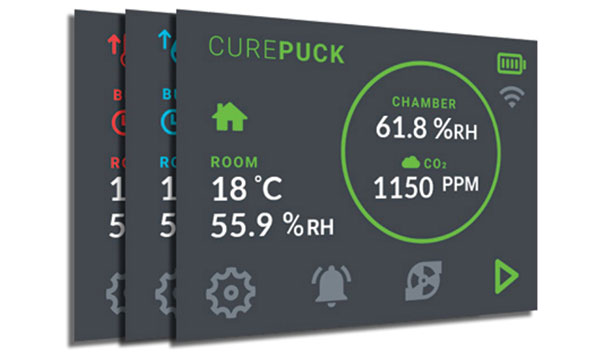

post your findings, in humid climates this is most challenging

post your findings, in humid climates this is most challenging