Thanks man - I'm at work taking some measurements now so I will find out the breaker rating info when I am home & get back to you. Option 1 seems the best, no? If applicable

-

As of today ICMag has his own Discord server. In this Discord server you can chat, talk with eachother, listen to music, share stories and pictures...and much more. Join now and let's grow together! Join ICMag Discord here! More details in this thread here: here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Growroom Electricity and Wiring

- Thread starter Phillthy

- Start date

Either way works fine. It depends on whether they spec a HACR breaker (Heating Air Conditioning Rated), and if so, the availability of them for your load center. It would probably be the less confusing of the two options in the future for trouble-shooting, and would be a little cheaper.

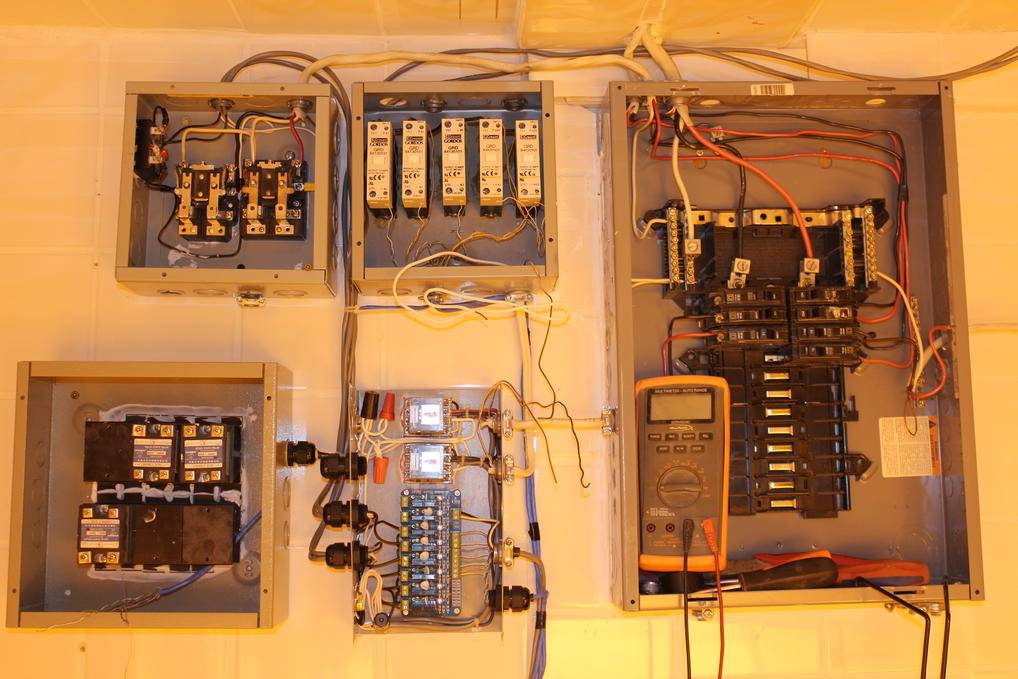

This one is for you Rives first pic of what i am talking about !

Now the problem,not everytime but almost each time i plug some electric load(tool/pump/etc.)in outlet feed from panel,or contact direct in panel(temporary ofcourse )the relay core(only the one hooked to delay on break acting by these i mean click going on and off )core is drived by ssr board,i know ssr leak some current but why only one of my relays is acting like this !does the delay on break was the culprint? obviously for me it was no acting when plug direct so ... but why,i need this delay in case of power outage(a/c relay)i may have another option but more costly so may i fix it?

)the relay core(only the one hooked to delay on break acting by these i mean click going on and off )core is drived by ssr board,i know ssr leak some current but why only one of my relays is acting like this !does the delay on break was the culprint? obviously for me it was no acting when plug direct so ... but why,i need this delay in case of power outage(a/c relay)i may have another option but more costly so may i fix it?

Now the problem,not everytime but almost each time i plug some electric load(tool/pump/etc.)in outlet feed from panel,or contact direct in panel(temporary ofcourse

Last edited:

I

Inspired333

1. yep inverter. i think the super cheap ones that plug right into the cigarette lighter will handle 80 watts. if you're running it right off the battery though, i think the ones with the lugs ready made start at around 400 watts or so.

2. either another inverter or else an appliance that runs on dc. in north america, the only applications i know they make dc appliances for are motor homes and (to a much lesser degree) off-the-grid type folks who prefer to use dc to avoid the inefficiency of an inverter.

Thanks bro.

So in answer #1; If I had an inverter that attaches to a battery with lugs, I can't hook it to my car's own installed battery (not a second battery) and power the device while driving the car? [if I ran wire through the firewall/car to the trunk for the device]

Lol

This one is for you Rives first pic of what i am talking about !

https://www.icmag.com/ic/picture.php?albumid=42986&pictureid=1043998View Image https://www.icmag.com/ic/picture.php?albumid=42986&pictureid=1043988View Image https://www.icmag.com/ic/picture.php?albumid=42986&pictureid=1043989View Imagehttps://www.icmag.com/ic/picture.php?albumid=42986&pictureid=1012577View Image

Now the problem,not everytime but almost each time i plug some electric load(tool/pump/etc.)in outlet feed from panel,or contact direct in panel(temporary ofcourse)the relay core(only the one hooked to delay on break acting by these i mean click going on and off )core is drived by ssr board,i know ssr leak some current but why only one of my relays is acting like this !does the delay on break was the culprint? obviously for me it was no acting when plug direct so ... but why,i need this delay in case of power outage(a/c relay)i may have another option but more costly so may i fix it?

Looks like you are doing a nice job, OBJ. Unfortunately, I cannot really understand what you are asking here but I'll take a stab at it.

Yes, all SSRs leak to an extent, and can have different levels of leakage. Some relays are more sensitive than others to the voltage levels that they need to operate. Perhaps you have a high-leakage SSR combined with a sensitive relay? Can you swap components around and see if the problem still exists? If this doesn't give you any answers, please re-phrase your question and post it again.

Thanks bro.

So in answer #1; If I had an inverter that attaches to a battery with lugs, I can't hook it to my car's own installed battery (not a second battery) and power the device while driving the car? [if I ran wire through the firewall/car to the trunk for the device]

Lol

You could if you could come up with a way to connect to the battery or the battery leads that would carry the current levels necessary. Any remote wiring should be protected with a fuse at the source end. You would need to make sure that the overall draw on the car's system is lower than it's charging systems output or you will drain your battery.

Looks like you are doing a nice job, OBJ. Unfortunately, I cannot really understand what you are asking here but I'll take a stab at it.

Yes, all SSRs leak to an extent, and can have different levels of leakage. Some relays are more sensitive than others to the voltage levels that they need to operate. Perhaps you have a high-leakage SSR combined with a sensitive relay? Can you swap components around and see if the problem still exists? If this doesn't give you any answers, please re-phrase your question and post it again.

Do i am so

at english lol!!!

at english lol!!!You almost got me

only the relay that is hooked to the delay on break(icm203) is acting the other's one are ok.As you said y will try another output of the ssr board i will also change relay .May i put some filter(capacitor or any devive that can do de job)filtering the spike from ssr?

only the relay that is hooked to the delay on break(icm203) is acting the other's one are ok.As you said y will try another output of the ssr board i will also change relay .May i put some filter(capacitor or any devive that can do de job)filtering the spike from ssr?

Last edited:

OBJ, sorry I missed your question here. In the past, I've had some luck with stopping sensitive relays from operating on triac leakage current by putting a pull-down resistor across the coil. If I recall correctly, for a 120v coil I was using a 5-watt, 3300 ohm (3.3k) resistor. You might want to step up to a 10-watt resistor depending on the duty cycle of the relay, and keep the resistor out in free air to help dissipate the heat.

N-P-Kali

Active member

You could if you could come up with a way to connect to the battery or the battery leads that would carry the current levels necessary. Any remote wiring should be protected with a fuse at the source end. You would need to make sure that the overall draw on the car's system is lower than it's charging systems output or you will drain your battery.

. In the past, I've had some luck with stopping sensitive relays from operating on triac leakage current by putting a pull-down resistor across the coil. If I recall correctly, for a 120v coil I was using a 5-watt, 3300 ohm (3.3k) resistor. You might want to step up to a 10-watt resistor depending on the duty cycle of the relay, and keep the resistor out in free air to help dissipate the heat.

If I were lurking this forum, and knew how tell tell time on a pocket watch, I would grab a pen and paper so I could jot down everything Rives types.

creeper327

Member

Can Anybody Help me out??? Line voltage drop in flip flop run.

Can Anybody Help me out??? Line voltage drop in flip flop run.

Hey guys, have a little problem with one of my flip flop gardens, hope some one with a little electrical theory can help me out, heres my conversations with Dan from DXHYDRO (awesome guy BTW) to give you some idea whats going on....

Please give me some more info about the problem:

How far is the cable from flipper to lamps? all lamp wire runs were replaced with 12/3 wire and spliced onto the 14/3 lamp cords....longest run is 30ft..coincidentally this is the only hood that fires up everytime so i dont think it is a distance issue.

What brand of ballasts –and type? all sunlight systems magnetic HPS 600w. 2 are brand new and the other ballast 4 range from 3-6 years old. (The lamp with the longest run that works everytime is actually hooked up through the flip flop to one of the older model ballast)... so i dont think it is the ballast because the brand new ones arnt working....I have bypassed the flip flop box completely and individually plugged each hood into one of the brand new ballast. 5 out of 6 worked that way.

Are they all doing the same thing and is it just on the A or B room? it is only doing it in room B. room A works perfect...

Also please tell me about the system – How many amps is the feeder circuit & what size wire was run from your main panel to control panel?

Did the problem just start – did the problem start occasionally and get worse? Does it happen every time?

Im using the power theif i purchased from you as my power supply for the ballasts...it is plugged into my 30amp dryer outlet.

I just want to get an idea of your setup before trying to find the cause.

Do you have a volt meter?

I did.... and ended up frying it doing what you told me not to do....BUT before i fried it, the wire splice at the hoods were actually reading below 120v even the one that was working... but the system is running on 240v....I then went to actual flip flop box to check the lamp output plugs....2 read 120...then i checked output that was working(longest run lamp) and it fried my meter..

I switched lamp runs from room A to side B on the flip flop box and it worked fine so i dont think it is the flip box..... I dunno im at a loss. im having my electrician come take a look at it.. at this point im thinking it has to be the the hoods or wire runs...but since i individually got 5of6 of the lamps working with the brand new ballast i dunno. I was doing some research on ballast ignitors and how when they age they can loose voltage output, etc..can you explain a little more of this theory?

How long of a run are we talking about: Room A; Room B (how far to each room) The longest run in room A is 15ft, While the longest run in room B is 30ft

And which room is having trouble? Or Is it BOTH rooms ONLY ROOM B!! ROOM A works perfectly everytime!

And does the problem happen after flipping a running lamp? Only flipping to room B

If the flipper is already in room A mode and you power up the ballast, will the lamps start? Yes, all six within a matter of seconds

If the flipper is in room B mode and you power up the ballasts, will they start? No, Only the one lamp/hood which is the longest lamp run will fully ignite within 10 seconds. All the other ballast will “arc” but won’t ignite, which leads me to think it’s igniter issues with the older ballast, except the 2 brand new ballast don’t work in room B….But when I completely bypass the flipper and plug them individually to one of the brand new ballast 6/6 work….

If you connect one of the suspect ballasts to the flipper –and then connect lamps without any extension, just the 15ft factory cord.

Are all of your lamps the same brand? Yes all brand new Ultrasun 600w HPS

Are there a couple ballasts that always work? Have your tried them with the different lamp combinations? All ballast work every time in room A, Only one lamp/ ballast combo work every time in room B.

The one ballast that didn’t work when connected directly: Did you try it with different lamps/hoods? Ive only tested the individual lamps in room B with one of the brand new ballast. With how my ballast are mounted some the lamp cords won’t reach to some of the ballast. But 5/6 did work when I tried the individual test, but I have had that hood/lamp that didn’t ignite during the test, work before with another ballast so I “think” it’s not a wiring issue..

How many out of your six do not want to work with the flipper (room A, room B)?

6/6 work every time, every filp, etc in room A

1/6 work every time, every flip, etc in room B

If there is some way that you can check the RUN voltage at the ballast, at the input to flipper and output of flipper that would be good info. If you have some thin wire (like some of the 14AWG from a cord), you might be able to wrap it around the black/white pin of the plug and then plug into the receptacle –SEE PIC. Would be a good way to get an inline voltage reading.

I will wait until I can get my buddy over here who’s a journeyman to help with the Line voltage…The trouble shooting has me stumped at this point, I want to lean towards the igniters but that wouldn’t explain the two brand new ballast not working in room B. BUT WHAT HAS ME THINKING IT IS THE IGNITOR/CAP AT THIS POINT.. IS THE TROUBLESHOOTER LINK YOU SENT ME DID SAY IF A MH CONVERSION LAMP WORKS, BUT A HPS DOES ITS MOST LIKELY A IGNITOR OR CAPICTOR ISSUE….BUT THEN AGAIN THE SAME SYMPTOMS WOULD BE COMMON OF A VOLTAGE DROP AS WELL??????

If anyone has an idea or needs more info let me know hahah Feel like im chasing my tail..

Can Anybody Help me out??? Line voltage drop in flip flop run.

Hey guys, have a little problem with one of my flip flop gardens, hope some one with a little electrical theory can help me out, heres my conversations with Dan from DXHYDRO (awesome guy BTW) to give you some idea whats going on....

Please give me some more info about the problem:

How far is the cable from flipper to lamps? all lamp wire runs were replaced with 12/3 wire and spliced onto the 14/3 lamp cords....longest run is 30ft..coincidentally this is the only hood that fires up everytime so i dont think it is a distance issue.

What brand of ballasts –and type? all sunlight systems magnetic HPS 600w. 2 are brand new and the other ballast 4 range from 3-6 years old. (The lamp with the longest run that works everytime is actually hooked up through the flip flop to one of the older model ballast)... so i dont think it is the ballast because the brand new ones arnt working....I have bypassed the flip flop box completely and individually plugged each hood into one of the brand new ballast. 5 out of 6 worked that way.

Are they all doing the same thing and is it just on the A or B room? it is only doing it in room B. room A works perfect...

Also please tell me about the system – How many amps is the feeder circuit & what size wire was run from your main panel to control panel?

Did the problem just start – did the problem start occasionally and get worse? Does it happen every time?

Im using the power theif i purchased from you as my power supply for the ballasts...it is plugged into my 30amp dryer outlet.

I just want to get an idea of your setup before trying to find the cause.

Do you have a volt meter?

I did.... and ended up frying it doing what you told me not to do....BUT before i fried it, the wire splice at the hoods were actually reading below 120v even the one that was working... but the system is running on 240v....I then went to actual flip flop box to check the lamp output plugs....2 read 120...then i checked output that was working(longest run lamp) and it fried my meter..

I switched lamp runs from room A to side B on the flip flop box and it worked fine so i dont think it is the flip box..... I dunno im at a loss. im having my electrician come take a look at it.. at this point im thinking it has to be the the hoods or wire runs...but since i individually got 5of6 of the lamps working with the brand new ballast i dunno. I was doing some research on ballast ignitors and how when they age they can loose voltage output, etc..can you explain a little more of this theory?

How long of a run are we talking about: Room A; Room B (how far to each room) The longest run in room A is 15ft, While the longest run in room B is 30ft

And which room is having trouble? Or Is it BOTH rooms ONLY ROOM B!! ROOM A works perfectly everytime!

And does the problem happen after flipping a running lamp? Only flipping to room B

If the flipper is already in room A mode and you power up the ballast, will the lamps start? Yes, all six within a matter of seconds

If the flipper is in room B mode and you power up the ballasts, will they start? No, Only the one lamp/hood which is the longest lamp run will fully ignite within 10 seconds. All the other ballast will “arc” but won’t ignite, which leads me to think it’s igniter issues with the older ballast, except the 2 brand new ballast don’t work in room B….But when I completely bypass the flipper and plug them individually to one of the brand new ballast 6/6 work….

If you connect one of the suspect ballasts to the flipper –and then connect lamps without any extension, just the 15ft factory cord.

Are all of your lamps the same brand? Yes all brand new Ultrasun 600w HPS

Are there a couple ballasts that always work? Have your tried them with the different lamp combinations? All ballast work every time in room A, Only one lamp/ ballast combo work every time in room B.

The one ballast that didn’t work when connected directly: Did you try it with different lamps/hoods? Ive only tested the individual lamps in room B with one of the brand new ballast. With how my ballast are mounted some the lamp cords won’t reach to some of the ballast. But 5/6 did work when I tried the individual test, but I have had that hood/lamp that didn’t ignite during the test, work before with another ballast so I “think” it’s not a wiring issue..

How many out of your six do not want to work with the flipper (room A, room B)?

6/6 work every time, every filp, etc in room A

1/6 work every time, every flip, etc in room B

If there is some way that you can check the RUN voltage at the ballast, at the input to flipper and output of flipper that would be good info. If you have some thin wire (like some of the 14AWG from a cord), you might be able to wrap it around the black/white pin of the plug and then plug into the receptacle –SEE PIC. Would be a good way to get an inline voltage reading.

I will wait until I can get my buddy over here who’s a journeyman to help with the Line voltage…The trouble shooting has me stumped at this point, I want to lean towards the igniters but that wouldn’t explain the two brand new ballast not working in room B. BUT WHAT HAS ME THINKING IT IS THE IGNITOR/CAP AT THIS POINT.. IS THE TROUBLESHOOTER LINK YOU SENT ME DID SAY IF A MH CONVERSION LAMP WORKS, BUT A HPS DOES ITS MOST LIKELY A IGNITOR OR CAPICTOR ISSUE….BUT THEN AGAIN THE SAME SYMPTOMS WOULD BE COMMON OF A VOLTAGE DROP AS WELL??????

If anyone has an idea or needs more info let me know hahah Feel like im chasing my tail..

Is this a new installation problem or has it been running for a while?

There was no answer to this question - "[FONT=Arial, Helvetica, sans-serif]if you connect one of the suspect ballasts to the flipper –and then connect lamps without any extension, just the 15ft factory cord."

When you are testing the individual lamps in room B with the new ballast, are you doing it through the full circuit from the flip box to the hood or are you taking the ballast into the room and hooking up locally?

It sounds to me like an ignitor issue from what you have described so far. Ignitors are specified for different distances - it's possible that the two new ballasts that won't fire the lamps are using short-distance rated ignitors.

You could pick up a long-distance ignitor and move it from ballast to ballast to see if that impacts the problem, or try moving the ignitors out to the hoods. It would take an extra wire to move the ignitor to the hood location, but that might still be cheaper than going with long-distance ignitors.

[/FONT]

There was no answer to this question - "[FONT=Arial, Helvetica, sans-serif]if you connect one of the suspect ballasts to the flipper –and then connect lamps without any extension, just the 15ft factory cord."

When you are testing the individual lamps in room B with the new ballast, are you doing it through the full circuit from the flip box to the hood or are you taking the ballast into the room and hooking up locally?

It sounds to me like an ignitor issue from what you have described so far. Ignitors are specified for different distances - it's possible that the two new ballasts that won't fire the lamps are using short-distance rated ignitors.

You could pick up a long-distance ignitor and move it from ballast to ballast to see if that impacts the problem, or try moving the ignitors out to the hoods. It would take an extra wire to move the ignitor to the hood location, but that might still be cheaper than going with long-distance ignitors.

[/FONT]

creeper327

Member

Is this a new installation problem or has it been running for a while?

There was no answer to this question - "[FONT=Arial, Helvetica, sans-serif]if you connect one of the suspect ballasts to the flipper –and then connect lamps without any extension, just the 15ft factory cord."

When you are testing the individual lamps in room B with the new ballast, are you doing it through the full circuit from the flip box to the hood or are you taking the ballast into the room and hooking up locally?

It sounds to me like an ignitor issue from what you have described so far. Ignitors are specified for different distances - it's possible that the two new ballasts that won't fire the lamps are using short-distance rated ignitors.

You could pick up a long-distance ignitor and move it from ballast to ballast to see if that impacts the problem, or try moving the ignitors out to the hoods. It would take an extra wire to move the ignitor to the hood location, but that might still be cheaper than going with long-distance ignitors.

[/FONT]

Room A has been running for 7+months. a few months ago i decided to add a flip flop with the adjacent room.

when i was doing the individual test i was plugging the ballast directly into lamp cords..Room B lamp runs range from 20ft to 35ft and they did fire up.. lol all the troubleshooting seems to contradict itself!

Room A has been running for 7+months. a few months ago i decided to add a flip flop with the adjacent room.

when i was doing the individual test i was plugging the ballast directly into lamp cords..Room B lamp runs range from 20ft to 35ft and they did fire up.. lol all the troubleshooting seems to contradict itself!

So Room B is a new installation or did it run for "a few months" and then the problem developed?

When you say that you plugged the ballast directly into the lamp cords, are you saying that it was done at the flip location and just bypassed around the flip?

If the installation is brand new, and if the lamps work from the flip location while bypassing the flip, then the problem could be in the relays doing the flip. You would need to see if they are using the normally open or the normally closed contacts and insure that there isn't something in the contacts or possibly a loose connection in the terminations.

creeper327

Member

So Room B is a new installation or did it run for "a few months" and then the problem developed?

Room B has been set up for awhile but i was using it as a veg room with a couple 1000w before i decided to add the flip flip box.. the problem started when i added the flip flop box.

When you say that you plugged the ballast directly into the lamp cords, are you saying that it was done at the flip location and just bypassed around the flip?

Yes i just bypassed the flipper

If the installation is brand new, and if the lamps work from the flip location while bypassing the flip, then the problem could be in the relays doing the flip. You would need to see if they are using the normally open or the normally closed contacts and insure that there isn't something in the contacts or possibly a loose connection in the terminations.

I hope so!!!..how can i find out which contacts theyre using????

I hope so!!!..how can i find out which contacts theyre using????

I assume that the relays have normally open (NO) and normally closed (NC) contacts. You will need to see if the relay is activated when it is driving Room B or if it is turned off. If the relay is activated, the NO contacts are used for that room. If the relay is off, then the NC contacts are being used.

It is also possible that he might have used single-pole relays to do the flip, in which case relays will be activated when either room is powered.

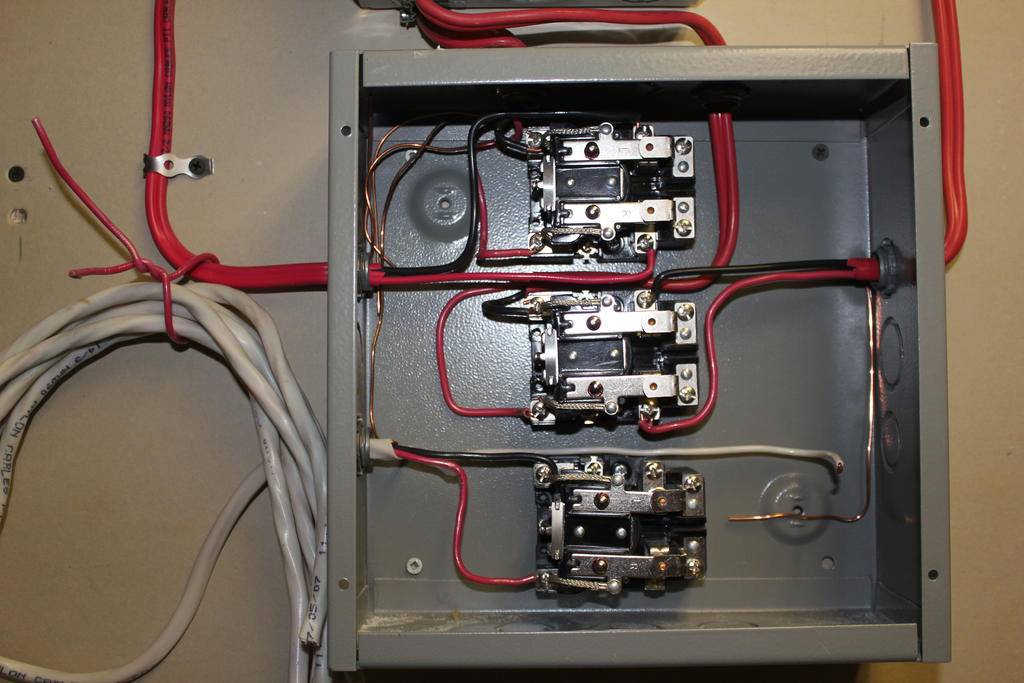

You might also try turning the power off to the panel (or pulling the plug) and carefully wiggle each connection around to make sure that all connections are tight. A good picture of the panel interior would help.

creeper327

Member

Sorry for the shitty quality!! full size pics are in my post in the Growroom design thread

Sorry for the shitty quality!! full size pics are in my post in the Growroom design thread

Jesus Christ. Link?

*edit* found it.

If those covers are removable, you may be able to access the contacts and see if there is anything stuck in them. There is definitely something going on there from what you have described. Why is that one contactor off of the DIN rail and hanging from the leads?

Those appear to be mechanically interlocked contactors - if the interlock isn't properly assembled, it could be jamming one contactor from pulling in. Can you trigger each room independently and see if you get a response out of the contactors?

Last edited: