Hydrostatic

Member

Have you looked at LabJack?

green_tea said:well the data gathering module is complete. along with the named pipe module (so the interface can talk to the phidget if need be, IE turning on / off things such as pumps)

time to interface it with the SQL server, and then work on the daunting task that is the UI

maybe if I ever get the UI to something that looks amazing, I'll post the code.

found some really cheap OEM CO2 sensors that work in the 0-4v range...

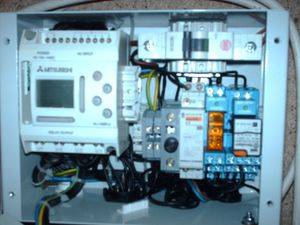

nUt_jOb said:Grower gone wild.. Do you program in Ladder Logic for that controller or maybe Function Block diagram?? I figured out ladder logic in a couple of hours more or less.