-

ICMag with help from Landrace Warden and The Vault is running a NEW contest in November! You can check it here. Prizes are seeds & forum premium access. Come join in!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gavita-Pro 1000w 400v (new generation hps)

- Thread starter Doc420

- Start date

* I wrote this on the fly, please forgive typos, omissions and spelling errors, I will edit this later.

That isn't how light distribution works when lamp is in a reflector. PPF (photosynthetic photon flux) is radaince, it's the energy (as photons per second) at(near) the lamp surface. PPFD is the irradiance measured some distance from the lamp, over a defined area (for density). What that means is 2000 PPF (i.e., umol/second, aka micromoles) does not convert into 2000 PPFD, even in the case of a "point source light". The higher the PPF the higher PPFD can be, if distance to canopy stays the same, or decreases.

An HID lamp in a reflector is not a point source light, so the light won't act as it does from the sun (in terms of direct vs diffuse photons, source (point of reflection) of photons, trajectory of photons, inverse square law, etc.). If you have a lamp that emits 2000 PPF hanging bare without a reflector, and it was four times smaller than the area it was irradiating*, it would be a point source light and the photons would act in a similar manner to what you seem to be describing.

* I cannot recall if the point source rule is the size of the destination needs to be at least four times the size of the source, but I think that's the rule.

When you hang a lamp X inches from the canopy, every inch higher means lower PPFD, being area (density) is a square meter. So if you had a lamp emitting 2000 PPF in a reflector, the PPFD could be anywhere from ~200 (and lower) to ~1000 (and higher)**. That said, I for one dislike using PPFD for indoor gardening, mostly because we use electric lighting and the canopy is never evenly irradiated, unlike a canopy outside under the sun. I prefer to use PPFD not defined as a meter^2, I like to define it in a pliable manner, e.g., it could be inch^2, four-inch^2, foot^2, etc. PPFD assumes the same irradiance over the whole area (meter^2), but that never happens indoors. One can come close if the canopy is the same size as the reflector (or LED array) and a few other things tweaked, but the canopy will never have even irradiance over the whole area, so the traditional definition of PPFD doesn't fit our use-case very well.

Yea, I agree 2000 PPF will leave the lamp; FWIW, 2000 PPF is not a unusual. However, you do not find PPFD by dividing PPF by area; see what I wrote above about point source lighting and how distance greatly affects irradiance.

To find PPFD under the sun you use a quantum sensor to count photons within 400-700 nm (ideally with the same 'weight' per photon) per second. Becuase the irradince is even under the sun, one can assume a meter^2 will have the same irradiance as reported by the quantum sensor. However, that is not the case indoors, or in a greenhouse, under lights. That is why many more measurements are needed, ex., one per inch^2 or one per three-inch^2, etc., to come close to a 'real' PPFD.

Not only that, but about 7-15% of the PPF is lost to the glass under the lamp (the heat shield), which also affects the path of some photons.

I am unsure why this is "the issue". We are in agreement with what you wrote, except the PPFD would not be 5000, that would be the irradiance of a much smaller area, not a meter^2 (re: very close to the lamp). FWIW, a poor-mans U.sphere can be had via a quantum sensor very close to a bare hanging lamp in a blacked out space. Doing so works because the same radiance is emitted from all sides of the lamp (except the ends), so the reading would be close to the reading one would get from a U.sphere.

In my experience testing MH vs HPS lamps with my quantum sensor, it is untrue that MH is a poor source for plant usable irradiace. MH delivers sufficient (very close to HPS) irradiance within 400-700 nm, ex., an MH vs HPS version of a 1,000 watt lamp of the same model/brand.

I am using the MH Digilux 1,000 watt, even though I have the HPS version right here, because the difference in irradiance is minor between the two (ex,. MH is ~50-150 umol/area/second less than HPS). [I am using the MH for reasons other than soley irradiance]

In the 'blue' range there are more photons per second vs the red range, all other things being equal, because the wavelengths for blue photons are shorter than red wavelengths.

There is simply no way to use any current market reflectors (I can think of) where the canopy of 5'x5' will be sufficiently and evenly irradiated (even in a reflective tent), i.e., > 800 umol/area/second.

The reasons to use a light mover are broader than to even the irradiance. Light movers are great for issues such as shading, Red:Far-Red ratio, phototropism, leaf heat, etc.

The reflector is one of the best 'big guns', if not the best, for a 5'x5' canopy. I also tested the SunSystem II and it wasn't good enough either.

Today I am going to modify the plant placemnt and hang the 600w Hortilux SuperHPS (with Eqauilver diffuser) next to the BlockBuster. So all plants will get more even (and higher) irradiance, no more red-headed step child plants getting only 500 umol/area/second on the outside. I am going to use Orca film to make a attachment to my tent for reflection and IR blocking. I will piggyback an IceBox for the SunSystem from the IceBox for the BlockBuster. That should give all plants at least sufficiently-bright light.

Ah, okay, thanks for the elaboration. However, I doubt very much that would come to be. There would be higher irradiance at the center with ever decreasing irradiance outward. The PPFD I bet would be < 1,000, maybe ~600-800.

I'm sorry, but it doesn't do both as a rule. If PPF is increased by 8%, as radiance from a lamp in a reflector, that doesn't necessarily equate into 8% higher PPFD. For example, if I run my ballast in 'super-lumens' mode, which is supposed to be a 10% increase in lumens from the lamp, the PPFD doesn't increase 10%. When we are dealing with diffuse, indirect, photons and glass diffusers (glass shield), as well as non-point source light, there is rarely a 1:1 relationship with anything.

I agree, and the same is true of most good electronic ballasts. However, all heat counts and I for one prefer to keep heat sources away from plants if I cam able. If one is concerned about cooling a room, the BTUs from a electronic ballast can be higher than expected.

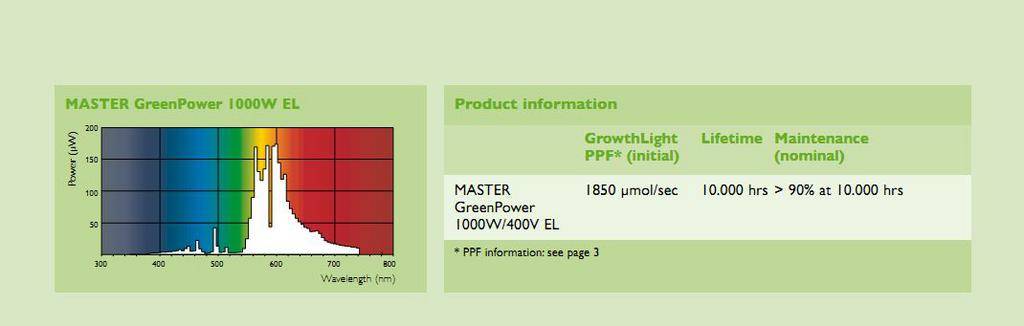

Philips uses a ppf of 1850 (or actually used, they have gone to 1900) micromoles ppf in their constant growlight guarantee program. Now initially we measure more than 2100 micromoles already from the lamp as a ppf, the HortiStar reflector is 96% efficient so that would leave you with even more than 2000 micromoles ppf to deliver to the surface. If you deliver that to 1 square meter then in theory you have a ppfd (d for density) of 2000 micromoles per second per square meter.spurr said:Hmm, I'm not sure that is quite right. IMO, it's too simple and isn't what happens in a real-world grow space. The claim made by Gavita is 1850 umol/sec, as PPF, not PPFD. That is only for the lamp without reflector. The foot print (light spread), irradiance peaks at canopy, direct vs diffuse light, etc., is controlled by the reflector. When the lamp is placed in the reflector the irradiance is much higher close to the lamp, due to the concentration from reflection, which isn't present in a U.sphere or when using a spectroradioemter.

For that lamp there would be more than 1,900 umol/area/second when it's in a reflector, just below the glass of the reflector. It's up to the reflector to do a 'good job' of getting the light to the canopy, ex., concentration vs spread.

For example, I have tested both 1,000 watt Digilux HPS and MH lamps using a new Galaxy electronic ballast in a BlockBuster 8" and SunSystem II reflector. With the lamps in the reflectors irradiance easily reaches ~1,500 umol/area/second (highest irradiance, under red light, for cannabis to reach peak rate of photosynthesis) below the lamp (many) inches from the glass. I have a Licor Li-190 quantum sensor and data logger, and I used it within my 5'x5' (I.D.) tent to test the 'useable' foot print area for high irradiance (i.e., > 800 umol/area/second) under both reflectors and all lamps. I tested using a 'hot spot' diffuser and not using a hot spot diffuser. Under no situations did any of the lamps or reflectors sufficiently irradiate the inside-center canopy area and the outside 1' (and more) of the 5'x5' canopy area (even in a reflective tent!). In all cases the irradiance was under 600 umol/area/second at the outside 1' (and more) of the 5'x5' area, when the inside canopy area was kept at high irradiance (~800 umol/area/second and higher). Granted, my tests were quick, dirty and flawed but they do offer worthwhile insight I think; this topic is something I plan to study correctly in the future.

Because of my testing with both reflectors with my quantum sensor, using a 600 watt Hortilux Super HPS, 400 watt MH generic and those two Digilux lamps, I am more convinced than ever that for horizontal growing, using narrower and longer canopies with a light mover is most ideal in terms of providing high irradiance at all plants. In other words square canopies are out, rectangle canopies are in; IMO anyway. I have setup a reflector and in-line fan (6") on a LightRail 3.5 without worry (just had to counter-balance the weight of teh fan); the LightRail 3.5 can hold/move up to ~150 lbs according to the LightRail tech support.

That isn't how light distribution works when lamp is in a reflector. PPF (photosynthetic photon flux) is radaince, it's the energy (as photons per second) at(near) the lamp surface. PPFD is the irradiance measured some distance from the lamp, over a defined area (for density). What that means is 2000 PPF (i.e., umol/second, aka micromoles) does not convert into 2000 PPFD, even in the case of a "point source light". The higher the PPF the higher PPFD can be, if distance to canopy stays the same, or decreases.

An HID lamp in a reflector is not a point source light, so the light won't act as it does from the sun (in terms of direct vs diffuse photons, source (point of reflection) of photons, trajectory of photons, inverse square law, etc.). If you have a lamp that emits 2000 PPF hanging bare without a reflector, and it was four times smaller than the area it was irradiating*, it would be a point source light and the photons would act in a similar manner to what you seem to be describing.

* I cannot recall if the point source rule is the size of the destination needs to be at least four times the size of the source, but I think that's the rule.

When you hang a lamp X inches from the canopy, every inch higher means lower PPFD, being area (density) is a square meter. So if you had a lamp emitting 2000 PPF in a reflector, the PPFD could be anywhere from ~200 (and lower) to ~1000 (and higher)**. That said, I for one dislike using PPFD for indoor gardening, mostly because we use electric lighting and the canopy is never evenly irradiated, unlike a canopy outside under the sun. I prefer to use PPFD not defined as a meter^2, I like to define it in a pliable manner, e.g., it could be inch^2, four-inch^2, foot^2, etc. PPFD assumes the same irradiance over the whole area (meter^2), but that never happens indoors. One can come close if the canopy is the same size as the reflector (or LED array) and a few other things tweaked, but the canopy will never have even irradiance over the whole area, so the traditional definition of PPFD doesn't fit our use-case very well.

Ex., if one write 1000 PPFD that really doesn't mean much to an indoor garden where the irradiance can be 500 umol/inch^2/second at one spot of the canopy and 1000 umol/inch^2/second in a different spot of the canopy (ex., hot-spot). So even the though the whole canopy could be 1000 PPFD, not all plants are getting the same irradiance, which equates to lower yield, growth, etc.

** to find PPFD of a lamp in a reflector (a non-point source light with much diffuse light) one would need to take many irradiance measurements with a quantum sensor (~144 over a meter^2), then average them to find PPFD. It's unlike under the sun, where one measurement is good, because under a lamp in a reflector the irradiance is uneven.

Now in a real world that will be a bit less because of losses to walls but I assure you that 2000 micromoles will leave that lamp. Tp calculate the ppfd you devide the number of photons per second by the surface in square meters.

Yea, I agree 2000 PPF will leave the lamp; FWIW, 2000 PPF is not a unusual. However, you do not find PPFD by dividing PPF by area; see what I wrote above about point source lighting and how distance greatly affects irradiance.

To find PPFD under the sun you use a quantum sensor to count photons within 400-700 nm (ideally with the same 'weight' per photon) per second. Becuase the irradince is even under the sun, one can assume a meter^2 will have the same irradiance as reported by the quantum sensor. However, that is not the case indoors, or in a greenhouse, under lights. That is why many more measurements are needed, ex., one per inch^2 or one per three-inch^2, etc., to come close to a 'real' PPFD.

Not only that, but about 7-15% of the PPF is lost to the glass under the lamp (the heat shield), which also affects the path of some photons.

The issue is that you can not measure the ppf of a lamp inside a reflector, you need an integrating sphere for that. You measure the ppfd at that specific spot. You can easily measure a ppfd of 5000 micromoles if you are close enough to the lamp.

I am unsure why this is "the issue". We are in agreement with what you wrote, except the PPFD would not be 5000, that would be the irradiance of a much smaller area, not a meter^2 (re: very close to the lamp). FWIW, a poor-mans U.sphere can be had via a quantum sensor very close to a bare hanging lamp in a blacked out space. Doing so works because the same radiance is emitted from all sides of the lamp (except the ends), so the reading would be close to the reading one would get from a U.sphere.

A MH delivers poor growlight in quantity micromols, I'm am not talking about light quality here.

In my experience testing MH vs HPS lamps with my quantum sensor, it is untrue that MH is a poor source for plant usable irradiace. MH delivers sufficient (very close to HPS) irradiance within 400-700 nm, ex., an MH vs HPS version of a 1,000 watt lamp of the same model/brand.

I am using the MH Digilux 1,000 watt, even though I have the HPS version right here, because the difference in irradiance is minor between the two (ex,. MH is ~50-150 umol/area/second less than HPS). [I am using the MH for reasons other than soley irradiance]

In the 'blue' range there are more photons per second vs the red range, all other things being equal, because the wavelengths for blue photons are shorter than red wavelengths.

To get an even reading you need a good reflector of course. Uniformity is the result of a good reflector. Sometimes two overlapping lights provide better uniformity.

I don't see why you wouldn't be able to distribute that light evenly without moving construvtions. Think about 2x600 is you can't cover it with one lamp.

There is simply no way to use any current market reflectors (I can think of) where the canopy of 5'x5' will be sufficiently and evenly irradiated (even in a reflective tent), i.e., > 800 umol/area/second.

The reasons to use a light mover are broader than to even the irradiance. Light movers are great for issues such as shading, Red:Far-Red ratio, phototropism, leaf heat, etc.

spurr said:I am so unhappy with the irradiance at the outside 1-1.5' of the canopy in the 5'x5' tent (even with a 'Cadillac' light system and tent) I am setting up my 600 watt Hortilux SuperHPS in the SunSystem II reflector, to provide extra light for the outer row plants, on two sides.

Reflector issue or maybe use 2x600 for more uniform spread.

The reflector is one of the best 'big guns', if not the best, for a 5'x5' canopy. I also tested the SunSystem II and it wasn't good enough either.

Today I am going to modify the plant placemnt and hang the 600w Hortilux SuperHPS (with Eqauilver diffuser) next to the BlockBuster. So all plants will get more even (and higher) irradiance, no more red-headed step child plants getting only 500 umol/area/second on the outside. I am going to use Orca film to make a attachment to my tent for reflection and IR blocking. I will piggyback an IceBox for the SunSystem from the IceBox for the BlockBuster. That should give all plants at least sufficiently-bright light.

of course. 5x5 ft is about 2.3 square meters. With the Pro 1000 at 115% let's say you get 2300 micromoles. That would be about a 1000 micromoles per meter.spurr said:I don't follow you here, I might be dense, but could you elaborate please?

Ah, okay, thanks for the elaboration. However, I doubt very much that would come to be. There would be higher irradiance at the center with ever decreasing irradiance outward. The PPFD I bet would be < 1,000, maybe ~600-800.

spurr said:That's good to know, thanks. So that 8% doesn't necessarily translate into 8% higher irradiance (PFPD) for the plants, but it does translate into 8% higher radiance (PPF).

It does both. When you raise the ppf you will raise the ppfd given the same reflector. ppf is like luminous flux but only measured in PAR spectrum and photons are counted. ppfd is like illuminance but measured in photons per second in the PAR spectrum.

I'm sorry, but it doesn't do both as a rule. If PPF is increased by 8%, as radiance from a lamp in a reflector, that doesn't necessarily equate into 8% higher PPFD. For example, if I run my ballast in 'super-lumens' mode, which is supposed to be a 10% increase in lumens from the lamp, the PPFD doesn't increase 10%. When we are dealing with diffuse, indirect, photons and glass diffusers (glass shield), as well as non-point source light, there is rarely a 1:1 relationship with anything.

spurr said:A problem I see is one of heat, I like to keep my ballast remote to my grow space, and at least remote to my canopy, to remove it as a heat source.

a HPS lamp converts about 60% or more to heat. The Philips 600W electronic ballast only dissipates 20W in heat. You can sleep on it, plus that convection heat will never reach your plants. For the 1000W it is a bit more but still nothing compared to the 600W+ of heat the lamp is producing.

I agree, and the same is true of most good electronic ballasts. However, all heat counts and I for one prefer to keep heat sources away from plants if I cam able. If one is concerned about cooling a room, the BTUs from a electronic ballast can be higher than expected.

I think what we disagree about is at least one basic important issue: ppf and ppfd.

See it as the same difference between luminous flux and illuminance, the lumens and lumens per square meter. You can easily calculate with that.

If a lamp would emit 100 lumens evenly over a 1 m2 area what would the illuminance be?

Same with a lamp and a reflector. If you know the efficiency of your reflector then you also know the reflector losses. So let's take the most efficient horticultural reflector at 96% efficiency (that is measured direct and indirect light, so total reflector efficiency) and put in a lamp that produces 1170 micromoles per second (ppf!). In total 96% of those photons (per second) would be spread over the surface: 1123 . So it the spread of the reflector was exactly 1x1 meter at a certain distance then the ppfd would be average above 1000 micromoles per second per meter. It does not say anything about the uniformity of that light on that surface.

That is one of the reasons btw why in horticulture the fixtures are always high above the crop: by overlapping at bigger distances they create a better uniformity. Of course illuminance over distance becomes less following the inverse square law (I thought 5 times the length of the light source btw), but that is compensated by the overlap of other lamps. You do not lose light, you spread it over a larger area which decreases the density which can be calculated using the inverse square law.

Now back to my 1123 micromoles per second emitted photons. Concentrate them on just half a square meter and you would have a ppfd of 2246 average. So the closer you get to the source the more light you will measure.

The lumatek super lumens switch adds only 5% btw, not 10%. That should account for the less readings you have because in theory the illuminance should rise as much as the luminous flux. Actually the efficiency of the lamp rises a bit. I have already published the results of that (ulbricht sphere!) measurement HERE. I can assure you that in an Ulbricht sphere we measure the total luminous flux in lumens and the PPF in micromoles per secod, not the illuminance or ppfd. Before we continue a discussion we need to find some common ground

If you not only look at the manufacturers specs (which show lower output specs for MH compared to HPS) but also test the lamps yourself (in an Ulbricht Sphere, like we do) you will find that they do considerable worse in ppf than HPS.

A last thing about the inverse square law and your loss of light over ditance. You do not lose light over distance, you just spread it out. Remember that 2x2m is not twice as big as 1x1m but 4 times as big. Always calculate with surface and you are good. Example:

ppfd average for 1000 micromole source:

0.5x0.5m (0,25 m2) 4000 micromoles

1x1m (1 m2) 1000 micromoles

1.4x1.4m (2 m2) 500 micromoles

2x2m (4m2) 250 micromoles

At what distance you get that coverage depends on your reflector. Of course you will have some stray light.

See it as the same difference between luminous flux and illuminance, the lumens and lumens per square meter. You can easily calculate with that.

If a lamp would emit 100 lumens evenly over a 1 m2 area what would the illuminance be?

Same with a lamp and a reflector. If you know the efficiency of your reflector then you also know the reflector losses. So let's take the most efficient horticultural reflector at 96% efficiency (that is measured direct and indirect light, so total reflector efficiency) and put in a lamp that produces 1170 micromoles per second (ppf!). In total 96% of those photons (per second) would be spread over the surface: 1123 . So it the spread of the reflector was exactly 1x1 meter at a certain distance then the ppfd would be average above 1000 micromoles per second per meter. It does not say anything about the uniformity of that light on that surface.

That is one of the reasons btw why in horticulture the fixtures are always high above the crop: by overlapping at bigger distances they create a better uniformity. Of course illuminance over distance becomes less following the inverse square law (I thought 5 times the length of the light source btw), but that is compensated by the overlap of other lamps. You do not lose light, you spread it over a larger area which decreases the density which can be calculated using the inverse square law.

Now back to my 1123 micromoles per second emitted photons. Concentrate them on just half a square meter and you would have a ppfd of 2246 average. So the closer you get to the source the more light you will measure.

The lumatek super lumens switch adds only 5% btw, not 10%. That should account for the less readings you have because in theory the illuminance should rise as much as the luminous flux. Actually the efficiency of the lamp rises a bit. I have already published the results of that (ulbricht sphere!) measurement HERE. I can assure you that in an Ulbricht sphere we measure the total luminous flux in lumens and the PPF in micromoles per secod, not the illuminance or ppfd. Before we continue a discussion we need to find some common ground

If you not only look at the manufacturers specs (which show lower output specs for MH compared to HPS) but also test the lamps yourself (in an Ulbricht Sphere, like we do) you will find that they do considerable worse in ppf than HPS.

A last thing about the inverse square law and your loss of light over ditance. You do not lose light over distance, you just spread it out. Remember that 2x2m is not twice as big as 1x1m but 4 times as big. Always calculate with surface and you are good. Example:

ppfd average for 1000 micromole source:

0.5x0.5m (0,25 m2) 4000 micromoles

1x1m (1 m2) 1000 micromoles

1.4x1.4m (2 m2) 500 micromoles

2x2m (4m2) 250 micromoles

At what distance you get that coverage depends on your reflector. Of course you will have some stray light.

can you elaborate on this please?

thanks...

I second the motion.

WE Vert Growers love to cool them naked bulbs... LOL

Please clarify the issue.

Ojo

I think what we disagree about is at least one basic important issue: ppf and ppfd.

See it as the same difference between luminous flux and illuminance, the lumens and lumens per square meter. You can easily calculate with that.

When discussing plant usable photons, it's best to use the terms "radiance" and "irradiance"; not "luminance" and "illumanice". That avoids confusion. However, I do not think we disagree about PPF and PPFD; it's hard to disagree on that because they are both well defined.

If a lamp would emit 100 lumens evenly over a 1 m2 area what would the illuminance be?

Lumen (luminance) is to PPF (radiance) as Lux (illuminance) is to PPFD (irradiance). Lux is measured at canopy, just like PPFD (irradiance).

100 lumens over m^2 would equate to 100 Lux (illuminance); but that's only with point-source light ...

Same with a lamp and a reflector.

No. In that case one is not using point-source light; that's the key.

If you know the efficiency of your reflector then you also know the reflector losses. So let's take the most efficient horticultural reflector at 96% efficiency (that is measured direct and indirect light, so total reflector efficiency) and put in a lamp that produces 1170 micromoles per second (ppf!). In total 96% of those photons (per second) would be spread over the surface: 1123 . So it the spread of the reflector was exactly 1x1 meter at a certain distance then the ppfd would be average above 1000 micromoles per second per meter. It does not say anything about the uniformity of that light on that surface.

Firstly, you didn't account for loss of photons due to glass shield (~7-10%); but that's besides the point. This topic has everything to do with uniformity of foot-print in our use-case, as well as distance to canopy. In your 'perfect-world' example, the total PPFD would indeed be > 1,000, but all plants within the m^2 would not get > 1,000 umol per second. That's the catch; in theoretical terms you are correct in terms of PPFD, but that isn't what happens in the real world. In the real world such a reflector does not exist. You can trust me or buy a quantum sensor and data reader/logger (~$1,200) and test for yourself. If you have the money I highly suggest buying what I use, it's worth its weight in gold.

I have actually tested what I am writing about with various reflectors, lamps and ballasts using my quantum sensor (I use the best one available for under a few thousand dollars). As well as I have studied light quantum physics for some years.

What this comes down to is real world application, not theoretical perfect-world math; even though in the case of the latter you are indeed correct.

In the end, there is no way the claims you made about the new Gavita-Pro lamp would come to bear in the real world when the lamp is in a reflector (even without a glass shield).

That is one of the reasons btw why in horticulture the fixtures are always high above the crop: by overlapping at bigger distances they create a better uniformity.

The further from the canopy the lower the PPFD ... in your example one can't have their cake and eat it too. Either one sacrifices intensity for spread, or spread for intensity. That is why using a light mover over a rectangle canopy is far better than stationary light over square canopy.

Of course illuminance over distance becomes less following the inverse square law (I thought 5 times the length of the light source btw), but that is compensated by the overlap of other lamps.

Yes, and a lamp in a reflector is not a point-source light, so the inverse square law does not apply. Very many growers misunderstand this critical distinction and try to apply inverse square law where it does not apply (ex., lamp in reflector or LED array).

What do you mean by "I thought 5 times the length of the light source btw"? Are you referring to my claim re the point-source 'rule'? IIRC, the point-source rule is about the size of the light source relative to the size of the area of irradiance.

... You do not lose light, you spread it over a larger area which decreases the density which can be calculated using the inverse square law.

You do loose light (less irradiance) in terms of irradiance over X area (X being smaller than the total irradiated area), the further away the lamp is placed. You cant use inverse square law for non-point-source lights.

Growers who use bare lamps can use inverse square law, but grower who use a reflector cannot.

BTW, don't you mean "you spread it over a larger area which increases the density", not "you spread it over a larger area which decreases the density"? Because in terms of PPFD density is the area of irradiance.

Now back to my 1123 micromoles per second emitted photons. Concentrate them on just half a square meter and you would have a ppfd of 2246 average. So the closer you get to the source the more light you will measure.

Yes, but not as PPFD because PPFD is defined as an area of a meter^2, that is why I wrote I prefer a 'loose' definition of PPFD vs the strict definition of m^2. This is why I prefer to use umol/area/second, instead of PPFD, so I can define "area" to fit my needs.

The lumatek super lumens switch adds only 5% btw, not 10%.

Have you tested that claim? I have not with a Lumatech but I have with my Galaxy. According to Galaxy, the maker of my ballast, it's 10%, not 5%. Regardless, I will re-test irradiance very close to lamp at 'normal' setting and then 'super' setting. That will give us our answer (with enough accuracy to make me happy but not enough to be called 'exact'); I will post results later.

That should account for the less readings you have because in theory the illuminance should rise as much as the luminous flux.

The word "theory" is key, that isn't what happens in our use-case.

Actually the efficiency of the lamp rises a bit. I have already published the results of that (ulbricht sphere!) measurement HERE. I can assure you that in an Ulbricht sphere we measure the total luminous flux in lumens and the PPF in micromoles per secod, not the illuminance or ppfd. Before we continue a discussion we need to find some common ground

I agree a U.sphere measures radiance, not irradiance. I never claimed otherwise.

Wow, it's awesome you have (or at least have access to) a U.sphere. They are very expensive. Whom do you work for, if you don't mind me asking?

If you not only look at the manufacturers specs (which show lower output specs for MH compared to HPS) but also test the lamps yourself (in an Ulbricht Sphere, like we do) you will find that they do considerable worse in ppf than HPS.

Only if you are compare applies to oranges, ex., brand X to brand Y. Granted, MH will have lower PPF than HPS, but not by a large enough margin to worry about, as shown in my testing with real world use-case (not in a U.sphere).

A last thing about the inverse square law and your loss of light over ditance. You do not lose light over distance, you just spread it out.

Tomato (toe-ma-toe) tomato (ta-ma-toe). By spreading light out (increasing density, i.e., area) you in effect 'loose' light (irradiance, e.g., intensity) over X area inside Y area.

Remember that 2x2m is not twice as big as 1x1m but 4 times as big. Always calculate with surface and you are good. Example:

ppfd average for 1000 micromole source:

0.5x0.5m (0,25 m2) 4000 micromoles

1x1m (1 m2) 1000 micromoles

1.4x1.4m (2 m2) 500 micromoles

2x2m (4m2) 250 micromoles

Only for point-source light, which is not the type light source the vast majority of growers use ...

In the end it comes down to real world vs perfect-world use-case. What I wrote is correct, take it or leave it as you will. That said, what you wrote is also correct (in part, re point-source vs non-point-source) but it's not representative of the real world use-case most growers employ.

What all this comes down to is the claims about the Gavita-Pro and PPFD you made are not correct when a grower is not using a point-source light.

BTW, I really like that you have (or at least have access to) a U.sphere, color me highly impressed! And I'm also impressed with your level of knowledge; thanks for this discussion, it's nice to chat with folks like you, KNNA, Avenger, etc., on these topics.

hehe well you and I have a completely different understanding of some definitions and applications. btw that gavita has no glass shield. I still really disagree with the way you look at loss of light. When you regard the light as a photon flux, you look at the photons between 400 and 700 nm and you count them, you can regard them as particles. So you can count how many photons leave the light source per second: There you have your ppf. You need an integrating sphere to measure the ppf, there is no other way you can measure it. Now though I totally agree with you that the inverse square law does not work until 5 times the largest diameter of the source , it does work as from that distance and even a bit before that distance it is pretty close.

It is important to know ppfd in micromomels per second per meter, all light (European horticultural) recipes are based on ppfd values. Light calculation programs are used to calculate in what configuration the right ppfd and best uniformity can be obtained. Those programs are based on digital models of the reflector/lamp combination and their output. Iso diagrams show the uniformity as well:

A quantum meter always measures ppfd: micromoles per second per meter. And I'm sure you use a good li-cor with cos phi correction etc if you spent that kind of money (or you should have ).

).

At least we do agree that it the inverse square law will work for HPS (and a bit quicker for MH) at a distance of five times the longest diameter of the source. You never heard me say that you should keep your lamps close to your crop. If you have one or just a few lamps, yes. If you have many: hang then high. better light penetration because light comes from various sides and better uniformity.

It is important to know ppfd in micromomels per second per meter, all light (European horticultural) recipes are based on ppfd values. Light calculation programs are used to calculate in what configuration the right ppfd and best uniformity can be obtained. Those programs are based on digital models of the reflector/lamp combination and their output. Iso diagrams show the uniformity as well:

A quantum meter always measures ppfd: micromoles per second per meter. And I'm sure you use a good li-cor with cos phi correction etc if you spent that kind of money (or you should have

At least we do agree that it the inverse square law will work for HPS (and a bit quicker for MH) at a distance of five times the longest diameter of the source. You never heard me say that you should keep your lamps close to your crop. If you have one or just a few lamps, yes. If you have many: hang then high. better light penetration because light comes from various sides and better uniformity.

Attachments

here is an interesting reader, it shows the ppf in micromoles, also for the HPI-T plus, which is a MH.

btw that gavita has no glass shield.

Really?! That isn't something most growers would be willing to use, then. In a greenhouse, sure, where the lamps can be hung many feet from the canopy, but not in an indoor garden where a 1,000 watt should be placed at most ~2.5 feet (just shy of a meter) from the canopy (due to irradiance issues and lack of head space above canopy). Ideally a grower would use a quantum sensor to find the best placement for their lamp/reflector to provide (ideally) ~1,000-1,300 umol/area/second over the whole canopy (so all plants get lots of light).

It makes no sense, why on earth would Gavita make a reflector that cannot accept a glass shield if they wish to sell the product to the mass of indoor growers? Add that much heat (at least 500 BTU of radiant heat from a 1,000 watt) with the BTU from the lamp/ballast (~3,500 BTU), and that lamp/reflector would heat the plants too much if placed at a sufficient distance in terms of irradiance (re "midday depression of photosynthesis", Vapor Pressure Deficit, leafs temp, Chl A and B, etc.).

Gavita better get on the ball if they want to sell their product to the mass of indoor cannabis growers ...

This is why a light mover and good reflector with glass is the best way to go in terms of horizontal garden and horizontally mounted lamp. Such a setup allows for (near) ideal irradiance, and the irradiance will be much more homogenous over the whole canopy.

I still really disagree with the way you look at loss of light. When you regard the light as a photon flux, you look at the photons between 400 and 700 nm and you count them, you can regard them as particles. So you can count how many photons leave the light source per second: There you have your ppf.

Yes, I am well aware

You need an integrating sphere to measure the ppf, there is no other way you can measure it.

You can use a quantum sensor placed very close to the lamp, to get a ballpark PPF, like I wrote before. This works because the lamp emits nearly equal photons in all directions (except at end of lamp). Granted, it won't be as accurate as U.sphere.

FWIW, I don't like calling U.sphere an integrating sphere, even though they are one in the same, because in plant physiology an integrating sphere is also used to find plant action spectrum (re absorptance, reflection and transmittance of photons). But an integrating sphere for a lamp and an integrating sphere for a leaf are very different tools (both though are many tens of thousands of dollars).

Now though I totally agree with you that the inverse square law does not work until 5 times the largest diameter of the source , it does work as from that distance and even a bit before that distance it is pretty close.

True. However IIRC, for HID lamps (i.e., clear) it's 5 times the longest dimension; it's 5 times the diameter for a frosted lamp. Further, a lamp in a reflector cannot be a point-source light as far as I know ...

It is important to know ppfd in micromomels per second per meter, all light (European horticultural) recipes are based on ppfd values. Light calculation programs are used to calculate in what configuration the right ppfd and best uniformity can be obtained.

I agree knowing PPFD is a good thing, but what you are suggesting just doesn't happen in the real world from a lamp in a reflector. Honestly, I am unsure why you are so determined to not agree, I have done the testing, have you?

I would agree 100% with everything you wrote, if the lamp was not in a reflector.

Those programs are based on digital models of the reflector/lamp combination and their output.

I too have access to such programs, and they are useful but they are not all you need; you also need to actually test the irradiance at canopy because those programs work in a vacuum of a perfect-world.

Iso diagrams show the uniformity as well:

Yes, but they do not show the actual irradiance at the canopy (point of measurement); it's all approximation and it's not that accurate from my testing. I have access to similar programs to what you are referring, and I have tested their accuracy relative to what really happens. KNNA and I have had this exact same debate before, and the flaws and limits of such programs are still present; as are the flaws and limits of using a quantum sensor.

Ideally one would use both theoretical and real world methods to quantify irradiance. One cannot use PPF to mathematically find irradiance every X inches (or millimeters) over the whole canopy, from a lamp in a reflector; this is a sperate issue than PPFD. This has to due with what I have been writing about: just because PPFD is 1,000 that doesn't mean (and in fact does not mean) all plants in that m^2 will get 1,000 umol/second.

A quantum meter always measures ppfd: micromoles per second per meter. AndI'm sure you use a good li-cor with cos phi correction etc if you spent that kind of money (or you should have).

No, it does not. A quantum sensor merely measures photons (ideally strictly between 400-700 nm with equal weight given to all photons) per second over the area of the sensor (~1"). Then, like I wrote before, the assumption is made that irradiance over a m^2 is the same as that from the quantum sensor. This is were the major flaw comes in when using a quantum sensor with a lamp in a reflector, to find PPFD. The reason is, spot X at the canopy will have irradiance A, but spot Y will have irradiance B, thus the quantum sensor will not give the true PPFD from only one measurement; unlike outside under the sun ...

And yes, my quantum sensor is model Li-190-SA and it's under a year old. I have my data logger configured to average the irradiance over 10 seconds to account for lamp flicker, this gives a more accurate measurement.

To find PPFD with a quantum sensor like I have, from a lamp in a reflector, one must make many measurements and then find the average. Ex., over a m^2 one should make at least 144 measurements ... this has been verified with my contacts at Li-cor (their staff of plant physiologists, which is the same field I am focusing on for my B.S. and then Masters).

I am going to buy two other types of quantum sensors from Li-cor soon. One is a 3' (meter) long "line quantum sensor" (model Li-191) which averages the irradiance over the whole length; thus one would only need say 18 measurements instead of 144, to find PPFD under a reflector. The other sensor I am going to get is the 'light bulb' type (model Li-193; link), which is great because it measures irradiance over a much greater degree (the 190-SA uses an 80 degree angle of measurement from the cosine correction, IIRC). The Li-193 is great to account for reflection from walls and leafs.

At least we do agree that it the inverse square law will work for HPS (and a bit quicker for MH) at a distance of five times the longest diameter of the source.

No, I'm sorry we do not. It's 5x the dimension, ex., distance of 5x the length of the filament. And we also do not agree one can use the inverse square law for a lamp in a reflector. If you want to use the inverse square law it must follow closely the 5x rule and it must not be in a reflector.

You never heard me say that you should keep your lamps close to your crop. If you have one or just a few lamps, yes. If you have many: hang then high. better light penetration because light comes from various sides and better uniformity.

Regardless of whether a grower has many lamps or a single lamp, distance should not be great if one wishes to keep irradiance higher (ex., > 1,000 umol/area/second). Distance should not be any greater for 10 lamps than 1; but the other point you made is correct: 'mixing' of photons from many lamps gives better homogeneity over the whole canopy. That reason, along with angle of photons, is exactly why I write what I do about using a light mover.

Also, if using a light mover a grower can get much higher efficiency in terms of yield per kilowatt-hour.

-----------------------------------

send me one of these new lamp setups so I may test it and report the findings.

I would only need to borrow it for a couple of days, I'll even pay for shipping! I will make very pretty and useful data set graphs for irradiance over a meter^2 (horizontal; à la "pineappaloupe" style chart; link):

... As well as a 'light-spread chart' showing irradiance at various distances and dimensions, à la UVBGuide light spread charts: http://www.uvguide.co.uk/makingspreadcharts.htm

Last edited by a moderator:

here is an interesting reader, it shows the ppf in micromoles, also for the HPI-T plus, which is a MH.

Yea I read that some time ago, it's good but it's also kind of flawed in some claims made. It's a good 'intro' though.

The impetus of our dialog came from your claim that the Gavita would be good for a 5'x5' canopy, and that PPFD would be as high as you claimed at a distance in which irradiance stays high (ex., ~2 feet from canopy). That is something I wholeheartedly disagree with at this point, if a grower wants to keep irradiance high. If you have the ability to send me one of those lamp setups I will test it over a m^2 and five feet squared too and report my findings, something I'm sure Gavita could make use of, if they care to find out the results that is.

hehe go check the grow reports. There is a lot of difference in the way we grow in Europe. We hardly use any air cooled reflectors in Europe. I suggest you read the specs of the lamp first before making comment about itReally?! That isn't something most growers would be willing to use, then. In a greenhouse, sure, where the lamps can be hung many feet from the canopy, but not in an indoor garden where a 1,000 watt should be placed at most ~2.5 feet (just shy of a meter) from the canopy (due to irradiance issues and lack of head space above canopy). Ideally a grower would use a quantum sensor to find the best placement for their lamp/reflector to provide (ideally) ~1,000-1,300 umol/area/second over the whole canopy (so all plants get lots of light).

It makes no sense, why on earth would Gavita make a reflector that cannot accept a glass shield if they wish to sell the product to the mass of indoor growers? Add that much heat (at least 500 BTU of radiant heat from a 1,000 watt) with the BTU from the lamp/ballast (~3,500 BTU), and that lamp/reflector would heat the plants too much if placed at a sufficient distance in terms of irradiance (re "midday depression of photosynthesis", Vapor Pressure Deficit, leafs temp, Chl A and B, etc.).

So based on your optimal light specs of 1000 - 1200 micromoles ppfd what would you recommend for hanging over 10 square meters? How would you calculate how many light you need for that? (based on the pro-line) 10 x 600W or 5 times 1000W (with the boost on to 115%). The DLI of that would be btw 43 for flowering (based on 1000 micromoles) and 12 hours of light. However, with a light mover the dli would drop depending on the surface you move your light. Here is some interesting reading as well. Generally, plants grown under a higher DLI will have smaller and thicker leaves, increased stem diameter, shorter internodes, increased rooting, and more lateral branches and flowers.

For a HPS lamp the longest dimension or diameter of the source is the length of the arc tube. Can we agree on that? For a reflector design the designer calculates with point sources, only they see the arc tube as an array of many point sources, it is really very complicated to design a good reflector. Of course inverse square law does not apply (completely) to a reflector, totally agree with about that. That's why we have the ISO diagram for example. For light calculations the reflector is measured at a specialized light lab and turned into a digital model with which you can calculate quite easily. Trust me, thousands of greenhouses in Holland work on that principle. It depends on the iso diagram what intensity of light you will get on your crop at what range and uniformity. You can for example not compare a bare bulb with a directional reflector. I do agree with that of course. But if we talk about total number of photons on a surface you can calculate with the ppf minus reflector losses. That is ultimately the amount of photons that will reach your crop. How you should position your reflector is other than a personal choice a matter of the spread of the reflector.True. However IIRC, for HID lamps (i.e., clear) it's 5 times the longest dimension; it's 5 times the diameter for a frosted lamp. Further, a lamp in a reflector cannot be a point-source light as far as I know ...

I agree knowing PPFD is a good thing, but what you are suggesting just doesn't happen in the real world from a lamp in a reflector. Honestly, I am unsure why you are so determined to not agree, I have done the testing, have you?

I would agree 100% with everything you wrote, if the lamp was not in a reflector.

And of course they are tested and brought into this digital model. Otherwise you would not be able to calculate the ppfd at plant height.I too have access to such programs, and they are useful but they are not all you need; you also need to actually test the irradiance at canopy because those programs work in a vacuum of a perfect-world.

No and that is why Li-cor also sell meters with arrays of sensors and we always measure that in a grid and never on a single point. Uniformity I can assure you is quite high in a greenhouse. I have worked closely with researchers from Wageningen University when they dit uniformity and ppfd measurements in rl situations. And they do measure the ppfd with a quantum meter.Yes, but they do not show the actual irradiance at the canopy (point of measurement); it's all approximation and it's not that accurate from my testing. I have access to similar programs to what you are referring, and I have tested their accuracy relative to what really happens. KNNA and I have had this exact same debate before, and the flaws and limits of such programs are still present; as are the flaws and limits of using a quantum sensor.

Ideally one would use both theoretical and real world methods to quantify irradiance. One cannot use PPF to mathematically find irradiance every X inches (or millimeters) over the whole canopy, from a lamp in a reflector; this is a sperate issue than PPFD. This has to due with what I have been writing about: just because PPFD is 1,000 that doesn't mean (and in fact does not mean) all plants in that m^2 will get 1,000 umol/second.

Well we disagree on this point. I totally agree with the manufacturer of your quantum meter that you do measure ppfd. A lux meter does not have a square meter sensor and yet it measures lumens per meter. The ppfd can be different in several measuring points under the reflector and for uniformity measurements you should measure many points (actually only half of them and then mirror them is enough). ppfd is the density of photons per second standardized per square meter. With one point measurement you do not measure a complete square meter of course.No, it does not. A quantum sensor merely measures photons (ideally strictly between 400-700 nm with equal weight given to all photons) per second over the area of the sensor (~1"). Then, like I wrote before, the assumption is made that irradiance over a m^2 is the same as that from the quantum sensor. This is were the major flaw comes in when using a quantum sensor with a lamp in a reflector, to find PPFD. The reason is, spot X at the canopy will have irradiance A, but spot Y will have irradiance B, thus the quantum sensor will not give the true PPFD from only one measurement; unlike outside under the sun ...

And yes, my quantum sensor is model Li-190-SA and it's under a year old. I have my data logger configured to average the irradiance over 10 seconds to account for lamp flicker, this gives a more accurate measurement.

To find PPFD with a quantum sensor like I have, from a lamp in a reflector, one must make many measurements and then find the average. Ex., over a m^2 one should make at least 144 measurements ... this has been verified with my contacts at Li-cor (their staff of plant physiologists, which is the same field I am focusing on for my B.S. and then Masters).

The Li-191 Line Quantum Sensor spatially averages PPFD over its one-meter length with just one sensor in a quartz rod so it is not suitable for uniformity measurement. As you said correctly, you need many points for that.I am going to buy two other types of quantum sensors from Li-cor soon. One is a 3' (meter) long "line quantum sensor" (model Li-191) which averages the irradiance over the whole length; thus one would only need say 18 measurements instead of 144, to find PPFD under a reflector. The other sensor I am going to get is the 'light bulb' type (model Li-193; link), which is great because it measures irradiance over a much greater degree (the 190-SA uses an 80 degree angle of measurement from the cosine correction, IIRC). The Li-193 is great to account for reflection from walls and leafs.

Then we do agree. For a non clear lightbulb it is the diameter of the bulb, for an arc tube is is the length of the arc in the arc tube, but again the reflector has the most influence on the pattern and uniformity. It should compensate for the angle and density of the light on the far ends while being balanced with the light right under the lamp, which by default is normally the hottest and most illuminated spot.No, I'm sorry we do not. It's 5x the dimension, ex., distance of 5x the length of the filament. And we also do not agree one can use the inverse square law for a lamp in a reflector. If you want to use the inverse square law it must follow closely the 5x rule and it must not be in a reflector.

I wholeheartedly disagree with you here. If you have many lamps, the space for it and the height you have a much better uniformity of light, plant penetration and and climate if you use overlapping lights. You do NOT have less light on your plants, you never lose light in mid-air. It is just a matter of calculating, based on the pattern and the throw of the reflector and the ppf of the source. If you double the ppf minus reflector losses you will double the ppfd, even with a reflector. Again, uniformity is something different. But if I have a lamp with a reflector output (ppf) of 1000 micromoles per second and I deliver that on one square meter in total the average ppfd will be 1000 micromoles per square meter per second. So you could measure 800 micromoles at the edges and 1200 right under the lamp if you are close to the lamp if the reflector does not spread the light to the sides. That is why horticultural reflectors use a different way of spreading the light: the side reflectors reflect the light in the opposite direction to compensate for the longer distance (hence lower density) of light at greater angles, see the iso diagram I published of the HR96.Regardless of whether a grower has many lamps or a single lamp, distance should not be great if one wishes to keep irradiance higher (ex., > 1,000 umol/area/second). Distance should not be any greater for 10 lamps than 1; but the other point you made is correct: 'mixing' of photons from many lamps gives better homogeneity over the whole canopy. That reason, along with angle of photons, is exactly why I write what I do about using a light mover.

I am sure you know about the DLI and how that is measured in mol·m-2·d-1. A plant uses 8-10 photons to bind one molecule of CO2. There is a direct relationship between the amount of par light and photosynthesis.Also, if using a light mover a grower can get much higher efficiency in terms of yield per kilowatt-hour.

Though they look really pretty and I appreciate your work please rest assured that Gavita have their reflectors measured at qualified laboratories specialized in optics and reflectors. As one of the market leaders they have many horticultural sites where they use thousands of their luminaries in one greenhouse alone. I have done some of those graphs myself too of course, also with different reflectors or using data from manufacturers, having no other data available, like this one for the Tophield pro that has recently been introduced as an alternative for the adjustawing in Europe to show the design flaw at the fitting end:It seems you may work for Gavita, if so, would you be willing to send me one of these new lamp setups so I may test it and report the findings?

I would only need to borrow it for a couple of days, I'll even pay for shipping! I will make very pretty and useful data set graphs for irradiance over a meter^2 (horizontal; à la "pineappaloupe" style chart; link):

... As well as a 'light-spread chart' showing irradiance at various distances and dimensions, à la UVBGuide light spread charts: ]

I had a bit of time this weekend but don't expect me to write these long posts every day

In the end, we can agree to disagree. What I would like to see though is any scientific papers backing your "per surface" instead of the standard "per square meter" theory. I think that is a basic disagreement we have. I refer you to your quantum meters manufacturer and the university papers about measuring light in a greenhouse.

I am sure you know about the DLI and how that is measured in mol·m-2·d-1. A plant uses 8-10 photons to bind one molecule of CO2. There is a direct relationship between the amount of par light and photosynthesis.

Yes, of course I do. I have written much about DLI and what would be close to ideal for cannabis, calculated from four different published papers on PPFD and cannabis, as well as PPFD data over daylength in Hawaii (re bell curve of irradiance over the whole daylength).

Though they look really pretty and I appreciate your work please rest assured that Gavita have their reflectors measured at qualified laboratories specialized in optics and reflectors. As one of the market leaders they have many horticultural sites where they use thousands of their luminaries in one greenhouse alone.

If that's true than you wouldn't have written what you did re 5'x5' and high irradiance. For highest Pn (rate of photosynthesis) cannabis uses ~1,500 PPFD (found via red light only during 60 minute irradiation*), but you shouldn't get caught up with the "PPFD" qualification, you should look at it as a goal of providing (at most) 1,500 umol/second to each plant within the whole canopy. Because they are not one in the same; PPFD does not tell us what each plant is getting in the canopy, under light from a reflector indoors; unlike under the sun outdoor or in a greenhouse.

* this is why irradiance over the whole day should not be 1,500 umol/area^2/second, the DLI would be too high. No cannabis studies, yet, have looked at DLI; but that is something I am going to study once I have my Li-Cor photosynthesis/Chl fluorometer chamber and RGB led lamp (provides up to 2,000 umol/area^2/second with variable red, green and blue ranges).

I had a bit of time this weekend but don't expect me to write these long posts every day

Yea this is my last post here too, because you do not want to accept what I am writing, even though I am correct and I have actually done the real-world testing ... and you have not

In the end, we can agree to disagree.

Funny, I was going to write the same thing.

What I would like to see though is any scientific papers backing your "per surface" instead of the standard "per square meter" theory. I think that is a basic disagreement we have. I refer you to your quantum meters manufacturer and the university papers about measuring light in a greenhouse.

(we are *not* discussing greenhouse growing, nor outdoor growing, that is one of the major flaws in your position)

There are no papers I am aware of re using a quantum sensor under artificial light indoors; which is why I am working in the field I am working in. Why don't you call up Li-cor and ask their plant physiologists about what I have been writing relative to using a quantum sensor indoors, if you don't believe me, and don't believe that I already talked to them?

It comes down to some basic misunderstands you have, and incorrect assumptions you are making. I am not making *any* assumptions relative to quantifying light indoors, I have done the testing and studied these topics ad nauseum for many years.

So, you won't be willing to send me one of those new setups to test in the real world? Hummm, that doesn't lend much credence to the belief of Gavita in their own product! The proof is in the pudding, and neither you, nor Gavita, have given us any pudding.

I for one do not trust any manufacture of grow equipment, I always verify what is claimed with unbiased analytical methods (re critical thinking). I do this because most manufacturers mislead and/or distort data they present to customers, if they do not out right lie. This is because they have large incentive to do anything they can to sell their products ...

Again, thanks for this discussion, even though we disagree it was nice chatting with you

@ all:

If anyone has access to this new setup and they want it tested, you could send it to me and I will test it and then send it back. I'm sure this new setup is good, but I very highly doubt it's groundbreaking, and I can all but guarantee it's not sufficient for a 5'x5' space.

Correct.

This lamp is normally used in big greenhouses.

The ballast only runs this 400v 1000w Greenpower lamp.

I have seen one in a shop and it looks really nice.

I will start a growreport as soon as i have it.

Do you have access to an 'extra' Gavita/Greenpower setup? That is, could you send me one so I may test it and then send it back to you a few days later? I'll pay for shipping from/to from Holland.

The system [ballast] is also made in a remote version.

I missed that point, and that's good news for Gavita if they want to sell this product to the mass of indoor cannabis growers. Now, if they would only modify the setup to allow for glass shield and air cooling (a la PL reflector air-cool addon*) Gavita may have some hope of selling this en mass to indoor cannabis growers.

* here is what I mean, this is the way I used my PL Medium and PL Maxima for air cooling (granted, this setup is rather poor at air cooling, but it's better than nothing)

Reflector/lamp:

Air cooled 'housing', which the reflector/lamp is placed within:

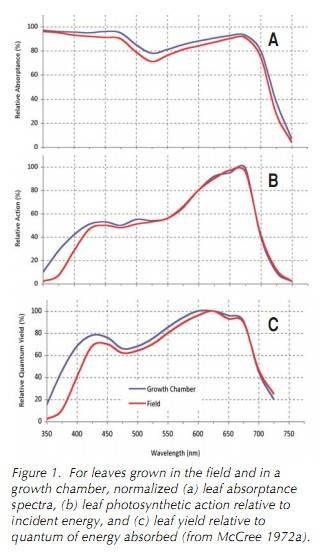

Here is the SPD for the lamp, and it's pretty poor. It's not something I would use because it lacks sufficient blue and green light, and the red:far-red ratio (re phytochrome A and B) as well as blue:far-red ratio (re cryptochrome and phytochrome B) would be quite low which means greater stretch/internode elongation:

My 2cents: don't bother with this setup due to lack of glass shield and poor SPD. If I am able to get one of these to test real world irradiance over X canopy area and BTU we would be able to gather a better idea of its efficacy; but I'm not holding my breath ...

My 2cents: don't bother with this setup due to lack of glass shield and poor SPD. If I am able to get one of these to test real world irradiance over X canopy area and BTU we would be able to gather a better idea of its efficacy; but I'm not holding my breath ...

For reference relative to SPD above, below is the most accurate action spectrum of photosynthesis, and quantum yield curve for higher plants at this time (thanks to the great K.McCree), re "quantum yield" from photons per wavelength. Using quantum yield curve is better (more accurate) than action spectrum of photosynthesis.

FWIW, I am going to make action spectrum(s) of photosynthesis and quantum yield curve(s) [graph 1B and 1C below, respectively] for cannabis at various life states (e.x., older leafs have higher quantum yield from blue light than younger leafs) and irradiances (re green light can have higher quantum yield than blue and even red under high irradiance white light) once I have the proper tools. I may buy tools from Qubit Systems instead of Li-cor, as well as an integrating sphere from ASD Inc. (even though the spectroradiometer one must also buy to use the integrating sphere is not ideal; and it's about $40K) because the former (Qubit) is much less expensive than the latter (Li-cor) which means I can do testing much sooner, albeit the former is also less accurate so it's a trade off. If anyone has ~$50,000-75,000 they want to donate to me* I can use Li-cor tools and ASD Inc. integrating sphere, and do the testing sooner rather than later

* I may attempt to start a US based non-profit for scientific study of ("medical") cannabis soon(ish), once I get to Colorado, so it could be tax deductible!

The above graphs were taken from the following (great) study by Li-Cor, I suggest everyone read this study if they have not yet. I have spoken with the author of that study/paper many times (he is a plant physiologist on staff at Li-cor):

FWIW, I am going to make action spectrum(s) of photosynthesis and quantum yield curve(s) [graph 1B and 1C below, respectively] for cannabis at various life states (e.x., older leafs have higher quantum yield from blue light than younger leafs) and irradiances (re green light can have higher quantum yield than blue and even red under high irradiance white light) once I have the proper tools. I may buy tools from Qubit Systems instead of Li-cor, as well as an integrating sphere from ASD Inc. (even though the spectroradiometer one must also buy to use the integrating sphere is not ideal; and it's about $40K) because the former (Qubit) is much less expensive than the latter (Li-cor) which means I can do testing much sooner, albeit the former is also less accurate so it's a trade off. If anyone has ~$50,000-75,000 they want to donate to me* I can use Li-cor tools and ASD Inc. integrating sphere, and do the testing sooner rather than later

* I may attempt to start a US based non-profit for scientific study of ("medical") cannabis soon(ish), once I get to Colorado, so it could be tax deductible!

"Comparison of Quantum Sensors with Different Spectral Sensitivities"

http://www.licor.com/env/pdf/light/TechNote126.pdf

http://www.licor.com/env/pdf/light/TechNote126.pdf

B

BrnCow

Input Voltage: 240-277 Volt

I am sure a local shop or distributor will be of service to you once they are in the shop in the US.

You repeatedly imply I do not test, but just apply theory. That is not the case. I understand that HPS lacks a lot of spectrum, still HPS is the most used lamp in this industry. If you read the documentation provided well you will see that Philips recommends the use of additional MH lighting when using these lamps in a climate room without sunlight. Still many growers use standard HPS lamps because they are efficient and "get the work done". Does it provide the best and prettiest of plants? I don't think so. I prefer a combination of blue or full spectrum and HPS. Do many people combine HPS and MH? I think not. But please, lamp manufacturers, publish your lamps ppf together with a good sspectrum diagram, that would make the market a lot more transparent already.

Cannabis is a plant that particularly loves red light in my opinion, and HPS being the most efficient source you get a good yield under HPS. You see a lot of growers do use a MH in vegetative growth with which they optimize their photosynthetic system and prepare the plant the best way for flowering.

Anyways, you might want to read a grow report about a single Pro 1000 in a 1.2m tent, there are a few tests on Dutch forums in a 1.5 m tent as well. Also you might want to look at the product at Gavita Holland's website before you assume anything about it (shielded, not available as a remote). Of course Gavita has the accompanying reflector as a remote too, the HortiStar reflector.

I think it is always wise to test if what a manufacturer promises is correct. There is a big difference however in using one reflector over using 20 reflectors together, specifically if you look at the throw and uniformity together with how high you want to hang your lamps.

I can tell you up front that the reflector efficiency is 96%.That already has been tested and verified in a light lab.

Thanks for the discussion, it was fun while it lasted, everyone can draw their own conclusions and they should of course, also finding more and also credible sources to support claims.

Gavita does research and lamp and reflector maintenance tests for their customers using this sphere, spectrometers, power analyzers and quantum meters.

edit: I incorporated a link to that licor in my previous posts.

You repeatedly imply I do not test, but just apply theory. That is not the case. I understand that HPS lacks a lot of spectrum, still HPS is the most used lamp in this industry. If you read the documentation provided well you will see that Philips recommends the use of additional MH lighting when using these lamps in a climate room without sunlight. Still many growers use standard HPS lamps because they are efficient and "get the work done". Does it provide the best and prettiest of plants? I don't think so. I prefer a combination of blue or full spectrum and HPS. Do many people combine HPS and MH? I think not. But please, lamp manufacturers, publish your lamps ppf together with a good sspectrum diagram, that would make the market a lot more transparent already.

Cannabis is a plant that particularly loves red light in my opinion, and HPS being the most efficient source you get a good yield under HPS. You see a lot of growers do use a MH in vegetative growth with which they optimize their photosynthetic system and prepare the plant the best way for flowering.

Anyways, you might want to read a grow report about a single Pro 1000 in a 1.2m tent, there are a few tests on Dutch forums in a 1.5 m tent as well. Also you might want to look at the product at Gavita Holland's website before you assume anything about it (shielded, not available as a remote). Of course Gavita has the accompanying reflector as a remote too, the HortiStar reflector.

I think it is always wise to test if what a manufacturer promises is correct. There is a big difference however in using one reflector over using 20 reflectors together, specifically if you look at the throw and uniformity together with how high you want to hang your lamps.

I can tell you up front that the reflector efficiency is 96%.That already has been tested and verified in a light lab.

Thanks for the discussion, it was fun while it lasted, everyone can draw their own conclusions and they should of course, also finding more and also credible sources to support claims.

Gavita does research and lamp and reflector maintenance tests for their customers using this sphere, spectrometers, power analyzers and quantum meters.

edit: I incorporated a link to that licor in my previous posts.

Attachments

You repeatedly imply I do not test, but just apply theory. That is not the case.

The only thing I impled about testing is you have not (or at least have not claimed to) tested in real world application respective to indoor use. You wrote many times you used programs to approximate PPFD from PPF* (which you found using a U.sphere), you never wrote you actually tested the irradiance with a quantum sensor.

* using inverse square law, which isn't applicable with a lamp in a reflector; thus the data you present as PPFD is moot. That is the crux of the issue ...

I understand that HPS lacks a lot of spectrum, still HPS is the most used lamp in this industry. If you read the documentation provided well you will see that Philips recommends the use of additional MH lighting when using these lamps in a climate room without sunlight.

So they want a grower to buy two lamps/reflectors just to get sufficient SPD?! It's better to simply buy one lamp that offers better SPD and high PPF, such as what I'm using, the Digilux 1,000w MH. The problem with using two lights is plants directly under the HPS won't get sufficient blue/green from the second light; so again, light homogeneity (re light quality, not light quantity) would be lacking.

But please, lamp manufacturers, publish your lamps ppf together with a good sspectrum diagram, that would make the market a lot more transparent already.

YES!!! I agree 101%!!! Too bad that won't happen because most manufacturers and brands either don't know or don't care about these issues (ex., SunMaster and SunPluse). That is why I have a plan to do so myself, and publish said data (SPD from spectroradiotmeter and PPF from U.Sphere) in a medium as yet to be decided upon (i.e., book vs web site).

Cannabis is a plant that particularly loves red light in my opinion, and HPS being the most efficient source you get a good yield under HPS. You see a lot of growers do use a MH in vegetative growth with which they optimize their photosynthetic system and prepare the plant the best way for flowering.

Cannabis is not much different than other "sun loving" higher C3 plants in terms of irradiance "quality" (i.e., SPD). And the difference in quantum yield (Pn) between blue, green and red light is not large; that is why quantum sensors attempt to give equal weight to all photons within RAR range.

Anyways, you might want to read a grow report about a single Pro 1000 in a 1.2m tent, there are a few tests on Dutch forums in a 1.5 m tent as well.

Will do, thanks

Also you might want to look at the product at Gavita Holland's website before you assume anything about it (shielded, not available as a remote). Of course Gavita has the accompanying reflector as a remote too, the HortiStar reflector.

So does Gavita offer an air-cooled addon, or at least an addon to use a glass shield?

I can tell you up front that the reflector efficiency is 96%.That already has been tested and verified in a light lab.

I agree, and IIRC my reflector (BlockBuster) uses the same insert as that in the Gavita reflector. I gotta double check that claim though.

yes, the blockbuster also uses miro or miro alike material.

Since the quantum yield is not much different in every color it doesn't make much difference in photosynthesis whether you use 300 micromoles of blue or red light. So, with HPS being at least 20-30% more efficient than MH you get more micromoles for your buck (and for a longer period) . For the correct plant morphology and the continuous regeneration of your photosynthetic system though you need blue light too. And Green. And...

. For the correct plant morphology and the continuous regeneration of your photosynthetic system though you need blue light too. And Green. And...

Since the quantum yield is not much different in every color it doesn't make much difference in photosynthesis whether you use 300 micromoles of blue or red light. So, with HPS being at least 20-30% more efficient than MH you get more micromoles for your buck (and for a longer period)

yes, the blockbuster also uses miro or miro alike material.

That is what I thought I remembered, that the BlockBuster uses the same insert as the Gavita.

Since the quantum yield is not much different in every color it doesn't make much difference in photosynthesis whether you use 300 micromoles of blue or red light. So, with HPS being at least 20-30% more efficient than MH you get more micromoles for your buck (and for a longer period).

True*, but photosynthesis isn't the whole story for best plant growth, yield, quality and health. However, under high irradiance white light (ex., > ~1,200 or 1,300 umol) green light can have quite a bit higher quantum yield than blue or red (due to saturation of 'upper' chloroplasts of leafs from blue and red photons; at which point green photons energize 'lower' chloroplasts of leafs).

The issue of green light and lower chloroplasts was not accounted for by Kieth McCree or Katsumi Inada; so their respective ASPs (Action Spectrum of Photosynthesis) and QYCs (Quantum Yield Curves) are not as accurate as they could be, esp. for indoor growing under high irradiance HID.

* However, I would not necessarily agree that "... HPS [is] at least 20-30% more efficient than MH ...", as a rule. And blue photons help increase RUE (Radiation Use Efficiency) by increasing Gs, thus this issue is not black-and-white.

For the correct plant morphology and the continuous regeneration of your photosynthetic system though you need blue light too. And Green. And...

Yuppers!