ReikoX

Knight of the BlackSvn

Part I - The Layout

So I've been wanting to upgrade my grow room for over a year now. My original plan was to redo the room after I got my yearly bonus. Unfortunately life got in the way, funds ran out, and I just kept growing.

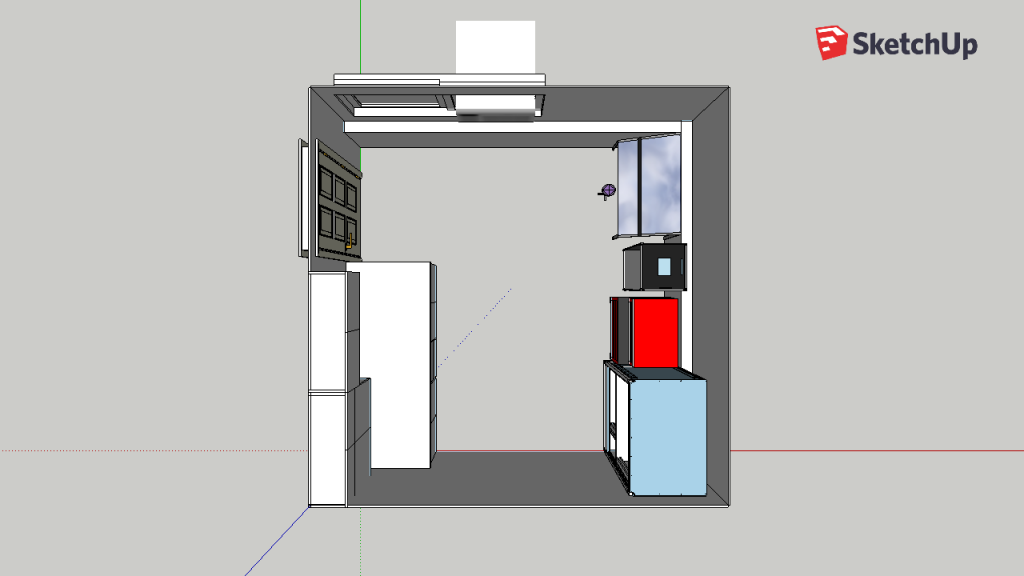

Let's start with what my workshop looks like currently. This is a top down view. The top and right side walls are exterior walls, 3' underground. The other two walls are adjacent to living spaces in the 1/2 basement.

There are a couple of things that I don't like about this room. First are the interior walls of the room itself. The walls themselves are framed, but instead of having sheetrock on them, they have paneling. I've hated this damn paneling since I moved in. Another issue I have is the door frame is about three inches too tall. This leaves a huge gap under the door.

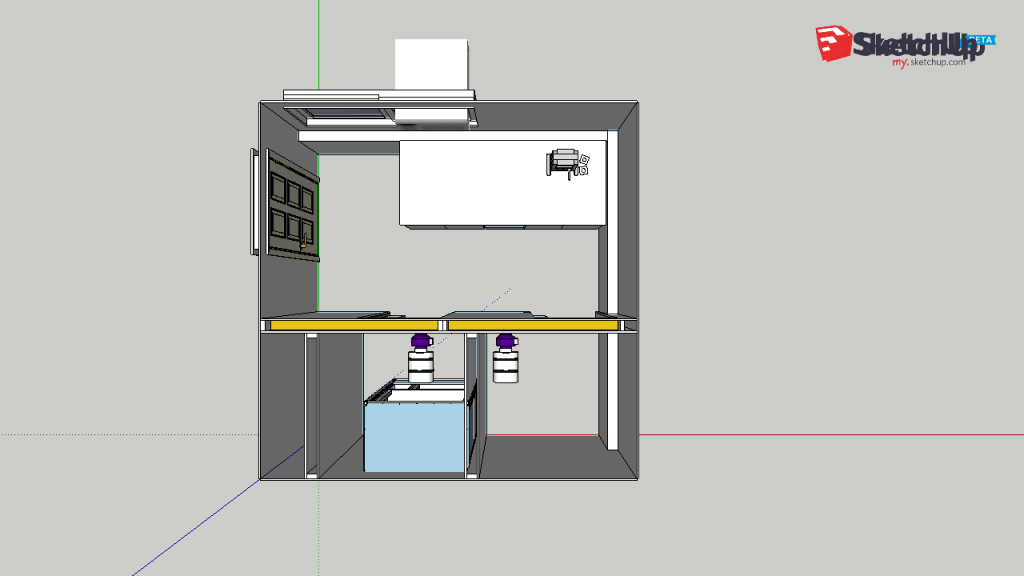

Workshop - current configuration

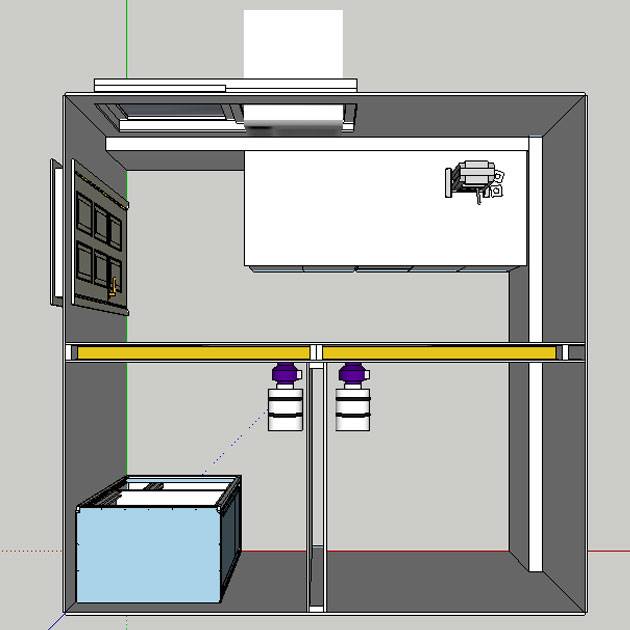

I have been trying to figure out the layout for quite some time now. I've started a discussion with @Mr.Sparkle about the layout of the room. The room is essentially 10' x 10'. My original idea was to split the room up with two 5' x 5' rooms. But I didn't want to get rid of my workbench or cab. I've grown attached to the no-till cab and the workbench is awesome for pressing rosin etc. The problem with this layout is there is not only 1' 10" between the workbench and the wall, but I could fit my other cab in the "veg" side. This layout also required the use of pocket doors because there is no way to open the doors with only 22" of clearance.

Workshop - version 1.3

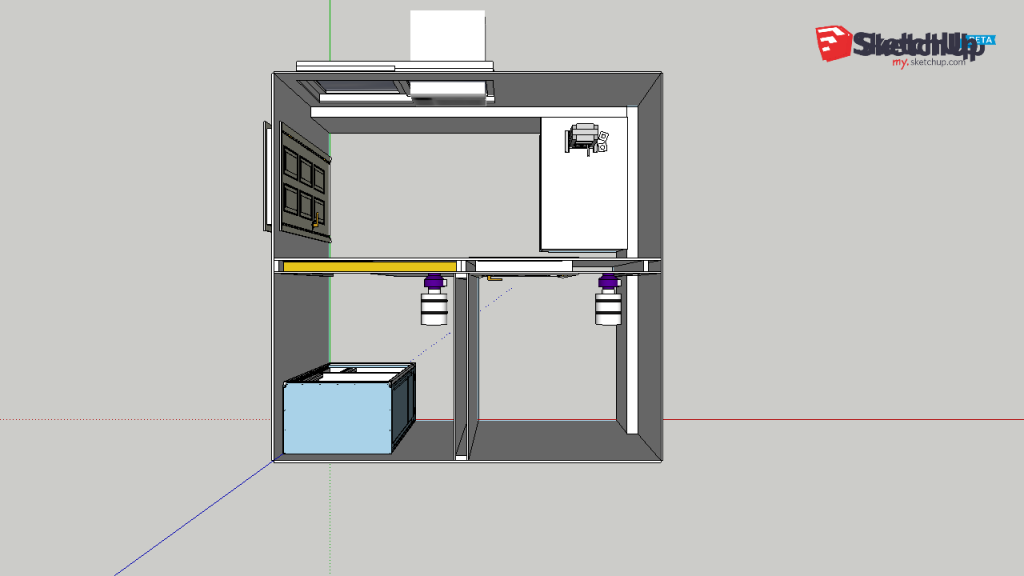

The next thing I tried was cutting the workbench in half and turning it 90 degrees. I didn't like the idea of cutting the workbench, plus it left a lot of unusable space in the grow room. It did solve the issue of having to use the pocket doors though.

Workshop - version 1.4

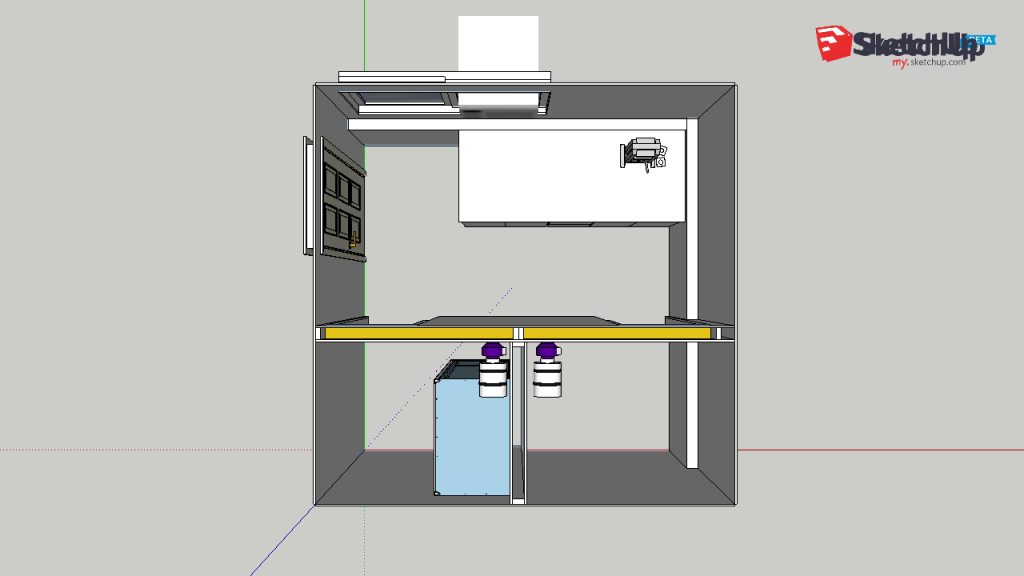

After some thought, I decided maybe it would be better to run a 4' x 5' room instead of a 5' x 5' room.. It would give me more room to keep the workbench and still be plenty of room to grow. Now we are getting somewhere.

Workshop - version 1.5

I figured a 4' x 4' grow area would be easier to light, so I played with having two 4' x 4' areas and a small drying area. I didn't really have enough room for the drying closet, it was only about 14" wide, not very useful.

Workshop - version 1.6

So I've been wanting to upgrade my grow room for over a year now. My original plan was to redo the room after I got my yearly bonus. Unfortunately life got in the way, funds ran out, and I just kept growing.

Let's start with what my workshop looks like currently. This is a top down view. The top and right side walls are exterior walls, 3' underground. The other two walls are adjacent to living spaces in the 1/2 basement.

There are a couple of things that I don't like about this room. First are the interior walls of the room itself. The walls themselves are framed, but instead of having sheetrock on them, they have paneling. I've hated this damn paneling since I moved in. Another issue I have is the door frame is about three inches too tall. This leaves a huge gap under the door.

Workshop - current configuration

I have been trying to figure out the layout for quite some time now. I've started a discussion with @Mr.Sparkle about the layout of the room. The room is essentially 10' x 10'. My original idea was to split the room up with two 5' x 5' rooms. But I didn't want to get rid of my workbench or cab. I've grown attached to the no-till cab and the workbench is awesome for pressing rosin etc. The problem with this layout is there is not only 1' 10" between the workbench and the wall, but I could fit my other cab in the "veg" side. This layout also required the use of pocket doors because there is no way to open the doors with only 22" of clearance.

Workshop - version 1.3

The next thing I tried was cutting the workbench in half and turning it 90 degrees. I didn't like the idea of cutting the workbench, plus it left a lot of unusable space in the grow room. It did solve the issue of having to use the pocket doors though.

Workshop - version 1.4

After some thought, I decided maybe it would be better to run a 4' x 5' room instead of a 5' x 5' room.. It would give me more room to keep the workbench and still be plenty of room to grow. Now we are getting somewhere.

Workshop - version 1.5

I figured a 4' x 4' grow area would be easier to light, so I played with having two 4' x 4' areas and a small drying area. I didn't really have enough room for the drying closet, it was only about 14" wide, not very useful.

Workshop - version 1.6