acespicoli

Well-known member

Ace Spicoli's Potting Mix for Grass

Soil

Nutrients

Moisture

Law of the Minimum

SME Saturated Media Extract - Soil Fertility Testing

#199

I was looking for some recipes and advice on DIY potting mix all organic easy to come by inexpensive mixes.

So here is my starting recipe ingredient costs:

Local free compost 30 gallons (this is from the local dump composted yard waste) free

Bale Peat Moss (im using 1/3 bale) - 3.8cu ft $10

Builders Sand 60 lbs -$3 bag

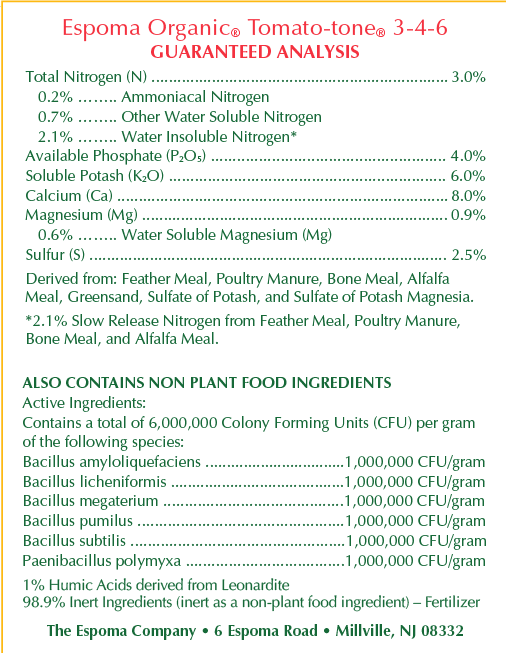

Tomato Tone 6 lbs (Mycos also in fert) $18 for 18lbs

Oyster shell 15 lbs- $10/50 lbs

Anyone have suggestions on what else should be in there?

This is a update recipe 2.22.2023 This will be the one stop post no need to read on

The latest greatest recipe page one post one. Always in edit mode constant improvement

All these will be easy mix recipes by volume pic a scoop any size and use it for = one part

This is based on how much you like to make how many containers you would like to fill

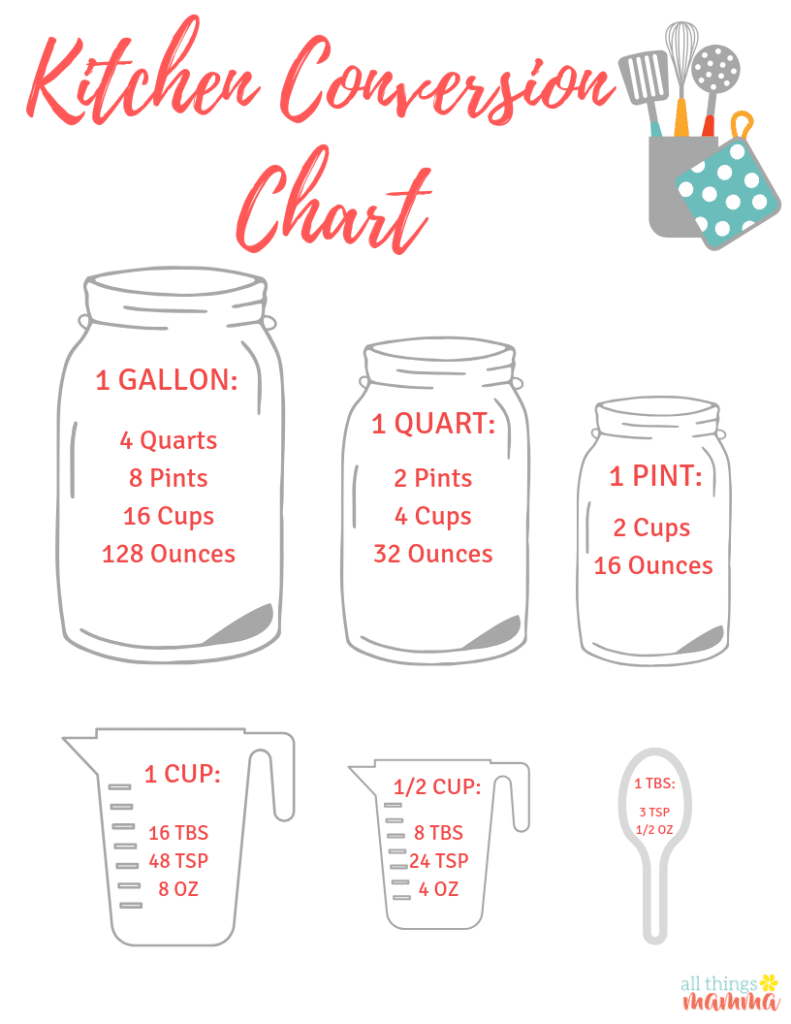

Most of the time a 1 or 5 gallon bucket or just a graduated marked bucket will do for measure

Small amounts will be teaspoon tablespoon and measuring cups

Basic

Peat Moss 2 parts

Vermiculite 1part

Compost 1 part

Tomato Tone (1.5 tbsp. of Tomato-tone for every 1 qt. of soil)

Oyster Shell

Flowers of Sulfur (Only needed for production of pungent aromas)

en.wikipedia.org

en.wikipedia.org

Advanced

Yard waste Compost EWC Earth Worm Castings 1 part that would give you up to about 20-25% +/-

or

EWC Earth Worm Castings 1 part that would give you up to about 20-25% +/-

compost usually introduces fungus gnats and other micro organisms insects not sterile its alive

for indoors this may present a problem which is why you need beneficial insects in your tent/room

Predatory Nematodes are the fix for soil larva of fungus gnats etc

Lady Bugs are the control for above ground plant pests

Find them on amazon

The peat moss is the bulk and high humus content makes up most of the mix

If you would like go ahead and try coco coir in place of peat ^ please report back results

You want to make sure its rinsed of all salts

The vermiculite is the wetting agent add micro elements as well as moisture and air

Compost is the nutrient and should comprise no more than 2 parts of the mix

Epsoma Tomato tone is mixed in based on pot size and later top dressed as needed (read the ingredients)

Composted Oyster meal is 21% more effective than fresh also its a huge source of chitin for terpene

Additionally, their shells tend to contain high levels of calcium carbonate (about 96%) this cuts the acidity of the peat as needed it will naturally buffer your soil as it dissolves adding calcium for strong cellular walls

, think vinegar and baking soda Feed Stores carry this chicken supplement

Sand will give you silica makes plants stronger, add weight to fabric pots stabilize top heavy plants

Water will be rain water with the naturally added nitrogen from atmosphere when available

Hollytone is now the preferable Epsoma ??? more to come edited 10.2023

For example, some of the most commonly described herbs such as sage, rosemary and lavender would be excluded from the botanical definition of a herb as they do not die down each year, and they possess woody stems.[8] In the wider sense, herbs may be herbaceous perennials but also trees,[10] subshrubs,[10] shrubs,[10] annuals,[10] lianas,[10] ferns,[10] mosses,[10] algae,[10] lichens,[8] and fungi.[8] Herbalism can utilize not just stems and leaves but also fruit, roots, bark and gums.[8] Therefore, one suggested definition of a herb is a plant which is of use to humans,[8] although this definition is problematic since it could cover a great many plants that are not commonly described as herbs.

en.wikipedia.org

en.wikipedia.org

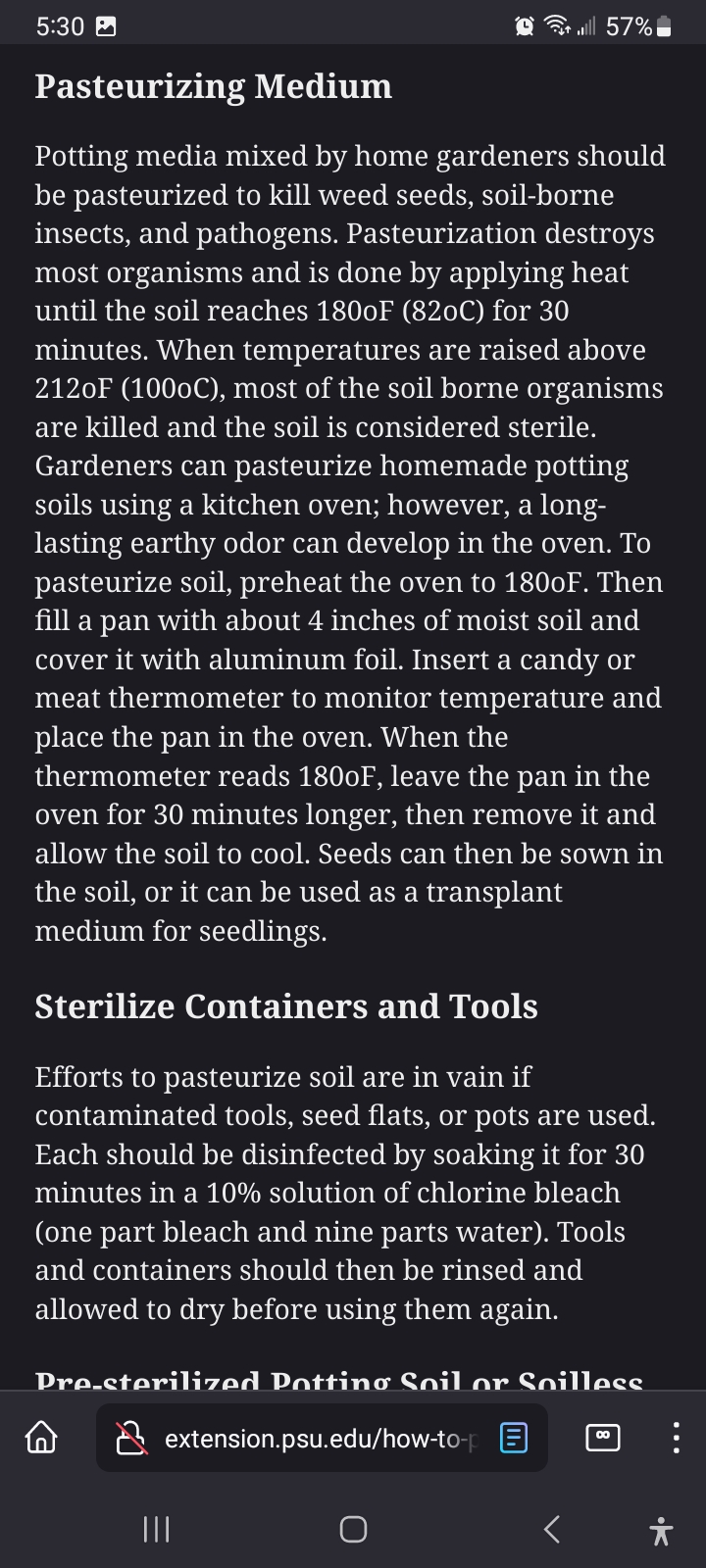

Soil steaming is regaining popularity to control weeds, soil-borne diseases and insect pests in agriculture. It is an effective and somewhat sustainable alternative (the drawback is the use of fossil fuel) to chemicals and fumigants to disinfect soil in greenhouses, high tunnels and open fields, and therefore useful in conventional and organic production systems. Hot steam heats up the substrate to temperatures that kill or inactivate weed seeds, nematodes, fungi, bacteria, and viruses by destroying cell structure and proteins. Steaming can also disinfect compost, potting soil, pots, tools, etc.

Frank in Germany developed soil steaming for agricultural purposes in 1888. In the U.S., however, agricultural steamers were first commercialized in 1893 and many steamer designs were developed to disinfect soils in greenhouses and nursery fields. Among the steam application tools were steam rakes, and tractor-drawn steam blades for small acres of high value crops. However, chemicals (pesticides) and fumigants such as methyl-bromide got on the market in the 1950's replacing soil steaming in soil pest management. Nowadays and since the phasing out of methyl-bromide after the Montreal Protocol in 1987, steaming is regaining popularity to disinfecting soil to manage soil-borne diseases, weeds and other pests.

Soil steaming is the transfer of energy from burning fuel through water steam to heat up the soil or substrate to pasteurization or sterilization temperatures. Steam temperature at low pressure is above 212°F, but steam releases large amount of energy when condensates into water heating up the soil with minimal moisture. Soil pasteurization occurs at 160-182°F, but soil sterilization is at the water boiling temperature (212°F). Soil steaming in agriculture is considered a pasteurization process since temperature recommendations are 160°F for 30 minutes to kill most pathogenic fungi, bacteria, insects and nematodes, and 182°F for 30 minutes to kill resistant weed seeds. However, time and energy are necessary to reach those temperatures at the desired soil depth.

Low-pressure steamer (By P. Byers)

Soil revitalization with beneficial microorganisms (soil activator, compost, etc.) may be necessary after soil steaming. When heating to the highest temperatures for sterilization deep into the soil, practically all organisms die, including beneficial ones. Killing soil microorganisms diminishes if not eliminates the soil biological activity, which will affect soil health and nutrient cycling and availability for subsequent crops. In addition, steam killed microorganisms release significant amount of nutrients that were tied up in the living phase of the soil. Therefore, an increase in nutrient availability may enhance vegetative growth in the first crop after treatment, but may require additional amendments or fertilizer for subsequent crops. Consequently, reintroduction of soil beneficial organisms becomes necessary to reactivate and/or maintain the soil biological processes for a healthy and productive soil. Use of quality compost or other type of soil activator will reintroduce beneficial organisms. In the case of compost, plant material infected with soil-borne diseases should not be added and adequate composting temperature must be reached. Otherwise, soil-borne diseases will be reintroduced into the steamed soil because pathogens have resistant structures that will survive organic matter decomposition if killing temperatures are not reached.

There are practically three low pressure steam application types: surface steaming, deep soil steaming and container/stack steaming. There are also several variations within each type as well as applicator systems/designs. Examples are the area sheet steaming, steaming hood, steaming harrow, steaming plough, steam injectors with vacuums, and others.

Surface steaming (By C. Millsap)

Soil surface steaming or sheet steaming is the most economical system and used in high tunnels, greenhouses and field. Steam is injected through a perforated pipe or hose of adequate material laid on the soil surface, so covering the area is necessary to force soil penetration. This steaming type is effective to treat the top 2 to 6 inches of the soil. It is a shallow treatment and the effective treatment depth depends on the time the steaming application last. The longer the application time, the deeper the soil reaches the recommended treatment temperature. Because of the shallow heat treatment, beds/rows should be prepared before steaming and maintained undisturbed after treatment to avoid bringing up pests from soil at depths where killing temperatures were not reached.

Deep soil steaming is more effective and last longer, several years, because it reaches soil depth of 1 to 1.5ft. It reduces the risk of bringing up pests from soil at depths where temperatures were not high enough for killing when working the ground. However, it is more expensive because the increase in energy consumption and treatment time. There are many variations to this technique, but the main ones are depth steaming with vacuum (negative pressure) and the combination of surface and depth steaming (sandwich) system. In the depth steaming with vacuum, surface applied steam is suctioned via pipes installed at the specified depth for this purpose. This is a permanent installation, so the initial cost is significant. Drainage pipes are also used for this purpose. In contrast, mobile systems inject steam at the desire depth and the vacuum pipes are on the surface covered with a hood of aluminum or other corrosion resistant material. The sandwich steaming system, developed in Europe, uses specialized equipment because of the high steam pressure and the necessary hood to force soil penetration. It is more efficient because steam simultaneously penetrates the soil from both the surface and at a specified depth, so it reduces the application time and the total fuel used.

Container/stack steaming is used for potting soil, compost, pots, tools, etc. The use of large containers, boxes, piles, or even dump trailers depends on the amount of substrate. High pressure chambers are also available for specific sterilization purposes. In addition, steam injection via manifolds and using suction systems can heat up large amounts of substrate more evenly. Steamed compost reduces the risk of reintroducing soil-borne diseases back into disinfected soil, but soil revitalization with beneficial microorganisms may be necessary.

Cost of steaming depends on equipment (capacity), area and soil depth to treat, which determine time and fuel needed. Many steamer designs are available, so renting cost may vary depending on the model. However, a low-pressure steamer designed to treat a 300sqft section down to 2inch deep would take approximately 2.5h and 10gal of Diesel. Finally, make sure to monitor temperature when steaming to confirm appropriate disinfection throughout the treated area.

Soil

Nutrients

Moisture

Law of the Minimum

SME Saturated Media Extract - Soil Fertility Testing

#199

I was looking for some recipes and advice on DIY potting mix all organic easy to come by inexpensive mixes.

So here is my starting recipe ingredient costs:

Local free compost 30 gallons (this is from the local dump composted yard waste) free

Bale Peat Moss (im using 1/3 bale) - 3.8cu ft $10

Builders Sand 60 lbs -$3 bag

Tomato Tone 6 lbs (Mycos also in fert) $18 for 18lbs

Oyster shell 15 lbs- $10/50 lbs

Anyone have suggestions on what else should be in there?

This is a update recipe 2.22.2023 This will be the one stop post no need to read on

The latest greatest recipe page one post one. Always in edit mode constant improvement

All these will be easy mix recipes by volume pic a scoop any size and use it for = one part

This is based on how much you like to make how many containers you would like to fill

Most of the time a 1 or 5 gallon bucket or just a graduated marked bucket will do for measure

Small amounts will be teaspoon tablespoon and measuring cups

Basic

Peat Moss 2 parts

Vermiculite 1part

Compost 1 part

Tomato Tone (1.5 tbsp. of Tomato-tone for every 1 qt. of soil)

Oyster Shell

Flowers of Sulfur (Only needed for production of pungent aromas)

Bacillus - Wikipedia

Advanced

Yard waste Compost EWC Earth Worm Castings 1 part that would give you up to about 20-25% +/-

or

EWC Earth Worm Castings 1 part that would give you up to about 20-25% +/-

compost usually introduces fungus gnats and other micro organisms insects not sterile its alive

for indoors this may present a problem which is why you need beneficial insects in your tent/room

Predatory Nematodes are the fix for soil larva of fungus gnats etc

Lady Bugs are the control for above ground plant pests

Find them on amazon

The peat moss is the bulk and high humus content makes up most of the mix

If you would like go ahead and try coco coir in place of peat ^ please report back results

You want to make sure its rinsed of all salts

The vermiculite is the wetting agent add micro elements as well as moisture and air

Compost is the nutrient and should comprise no more than 2 parts of the mix

Epsoma Tomato tone is mixed in based on pot size and later top dressed as needed (read the ingredients)

Composted Oyster meal is 21% more effective than fresh also its a huge source of chitin for terpene

Additionally, their shells tend to contain high levels of calcium carbonate (about 96%) this cuts the acidity of the peat as needed it will naturally buffer your soil as it dissolves adding calcium for strong cellular walls

, think vinegar and baking soda Feed Stores carry this chicken supplement

Sand will give you silica makes plants stronger, add weight to fabric pots stabilize top heavy plants

Water will be rain water with the naturally added nitrogen from atmosphere when available

Hollytone is now the preferable Epsoma ??? more to come edited 10.2023

For example, some of the most commonly described herbs such as sage, rosemary and lavender would be excluded from the botanical definition of a herb as they do not die down each year, and they possess woody stems.[8] In the wider sense, herbs may be herbaceous perennials but also trees,[10] subshrubs,[10] shrubs,[10] annuals,[10] lianas,[10] ferns,[10] mosses,[10] algae,[10] lichens,[8] and fungi.[8] Herbalism can utilize not just stems and leaves but also fruit, roots, bark and gums.[8] Therefore, one suggested definition of a herb is a plant which is of use to humans,[8] although this definition is problematic since it could cover a great many plants that are not commonly described as herbs.

Cannabis - Wikipedia

Soil Steaming to Reduce the Incidence of Soil-borne Diseases, Weeds and Insect Pests

Published: November 24, 2020

Soil steaming is regaining popularity to control weeds, soil-borne diseases and insect pests in agriculture. It is an effective and somewhat sustainable alternative (the drawback is the use of fossil fuel) to chemicals and fumigants to disinfect soil in greenhouses, high tunnels and open fields, and therefore useful in conventional and organic production systems. Hot steam heats up the substrate to temperatures that kill or inactivate weed seeds, nematodes, fungi, bacteria, and viruses by destroying cell structure and proteins. Steaming can also disinfect compost, potting soil, pots, tools, etc.

Frank in Germany developed soil steaming for agricultural purposes in 1888. In the U.S., however, agricultural steamers were first commercialized in 1893 and many steamer designs were developed to disinfect soils in greenhouses and nursery fields. Among the steam application tools were steam rakes, and tractor-drawn steam blades for small acres of high value crops. However, chemicals (pesticides) and fumigants such as methyl-bromide got on the market in the 1950's replacing soil steaming in soil pest management. Nowadays and since the phasing out of methyl-bromide after the Montreal Protocol in 1987, steaming is regaining popularity to disinfecting soil to manage soil-borne diseases, weeds and other pests.

Soil steaming is the transfer of energy from burning fuel through water steam to heat up the soil or substrate to pasteurization or sterilization temperatures. Steam temperature at low pressure is above 212°F, but steam releases large amount of energy when condensates into water heating up the soil with minimal moisture. Soil pasteurization occurs at 160-182°F, but soil sterilization is at the water boiling temperature (212°F). Soil steaming in agriculture is considered a pasteurization process since temperature recommendations are 160°F for 30 minutes to kill most pathogenic fungi, bacteria, insects and nematodes, and 182°F for 30 minutes to kill resistant weed seeds. However, time and energy are necessary to reach those temperatures at the desired soil depth.

Low-pressure steamer (By P. Byers)

Soil revitalization with beneficial microorganisms (soil activator, compost, etc.) may be necessary after soil steaming. When heating to the highest temperatures for sterilization deep into the soil, practically all organisms die, including beneficial ones. Killing soil microorganisms diminishes if not eliminates the soil biological activity, which will affect soil health and nutrient cycling and availability for subsequent crops. In addition, steam killed microorganisms release significant amount of nutrients that were tied up in the living phase of the soil. Therefore, an increase in nutrient availability may enhance vegetative growth in the first crop after treatment, but may require additional amendments or fertilizer for subsequent crops. Consequently, reintroduction of soil beneficial organisms becomes necessary to reactivate and/or maintain the soil biological processes for a healthy and productive soil. Use of quality compost or other type of soil activator will reintroduce beneficial organisms. In the case of compost, plant material infected with soil-borne diseases should not be added and adequate composting temperature must be reached. Otherwise, soil-borne diseases will be reintroduced into the steamed soil because pathogens have resistant structures that will survive organic matter decomposition if killing temperatures are not reached.

There are practically three low pressure steam application types: surface steaming, deep soil steaming and container/stack steaming. There are also several variations within each type as well as applicator systems/designs. Examples are the area sheet steaming, steaming hood, steaming harrow, steaming plough, steam injectors with vacuums, and others.

Surface steaming (By C. Millsap)

Soil surface steaming or sheet steaming is the most economical system and used in high tunnels, greenhouses and field. Steam is injected through a perforated pipe or hose of adequate material laid on the soil surface, so covering the area is necessary to force soil penetration. This steaming type is effective to treat the top 2 to 6 inches of the soil. It is a shallow treatment and the effective treatment depth depends on the time the steaming application last. The longer the application time, the deeper the soil reaches the recommended treatment temperature. Because of the shallow heat treatment, beds/rows should be prepared before steaming and maintained undisturbed after treatment to avoid bringing up pests from soil at depths where killing temperatures were not reached.

Deep soil steaming is more effective and last longer, several years, because it reaches soil depth of 1 to 1.5ft. It reduces the risk of bringing up pests from soil at depths where temperatures were not high enough for killing when working the ground. However, it is more expensive because the increase in energy consumption and treatment time. There are many variations to this technique, but the main ones are depth steaming with vacuum (negative pressure) and the combination of surface and depth steaming (sandwich) system. In the depth steaming with vacuum, surface applied steam is suctioned via pipes installed at the specified depth for this purpose. This is a permanent installation, so the initial cost is significant. Drainage pipes are also used for this purpose. In contrast, mobile systems inject steam at the desire depth and the vacuum pipes are on the surface covered with a hood of aluminum or other corrosion resistant material. The sandwich steaming system, developed in Europe, uses specialized equipment because of the high steam pressure and the necessary hood to force soil penetration. It is more efficient because steam simultaneously penetrates the soil from both the surface and at a specified depth, so it reduces the application time and the total fuel used.

Container/stack steaming is used for potting soil, compost, pots, tools, etc. The use of large containers, boxes, piles, or even dump trailers depends on the amount of substrate. High pressure chambers are also available for specific sterilization purposes. In addition, steam injection via manifolds and using suction systems can heat up large amounts of substrate more evenly. Steamed compost reduces the risk of reintroducing soil-borne diseases back into disinfected soil, but soil revitalization with beneficial microorganisms may be necessary.

Cost of steaming depends on equipment (capacity), area and soil depth to treat, which determine time and fuel needed. Many steamer designs are available, so renting cost may vary depending on the model. However, a low-pressure steamer designed to treat a 300sqft section down to 2inch deep would take approximately 2.5h and 10gal of Diesel. Finally, make sure to monitor temperature when steaming to confirm appropriate disinfection throughout the treated area.

Last edited: