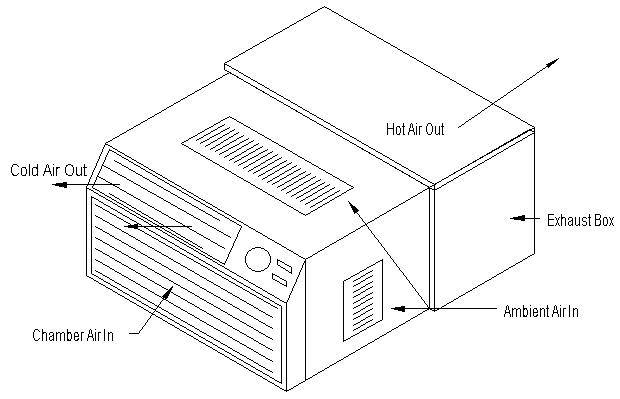

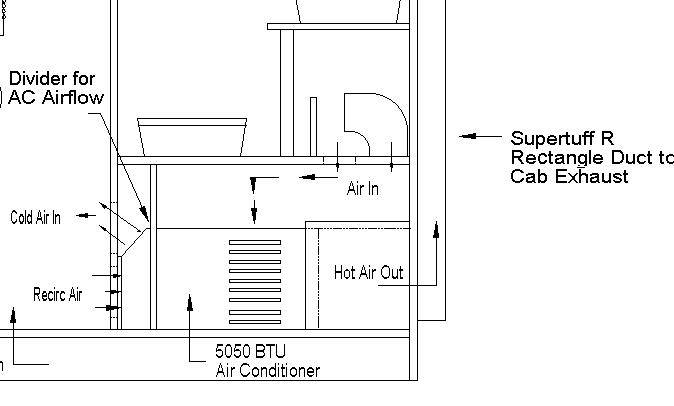

I built a fully enclosed AC box... tried some smaller fans, but the only thing that makes it work like a charm is a 6" vortex on a fan speed controller.

I shouldn't have fscked around for so long.. kept trying to avoid the $$$.. but in the end. the vortex is what worked for me.

-dh

I shouldn't have fscked around for so long.. kept trying to avoid the $$$.. but in the end. the vortex is what worked for me.

-dh