JacuzziSplot

Member

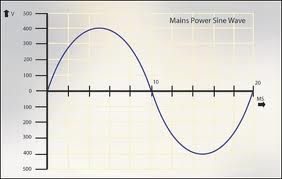

Its a Triac and it works by controlling when power goes to the fan based on the AC frequency.

The more you turn the dial down the higher the signal has to be on this curve to turn the fan on.

The more you turn the dial down the higher the signal has to be on this curve to turn the fan on.