Ca++

Well-known member

Following on from the chat about fan power, I thought a look at ducting could be useful

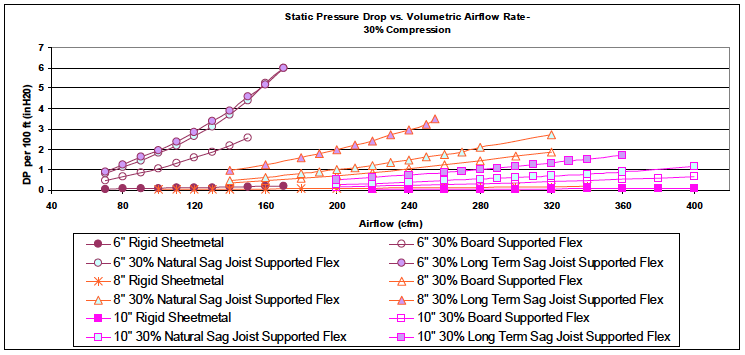

Here is a pic from the link

Fully stretched flexi is very similar to metal tube. We were looking at 4" carbons, which typically scrub about 200m2/h or 120cfm for this graph. We don't have 4" tested, but the 6" results speak loudly. So 6" laid out on a solid surface, pulled out to the point that you could get maybe half again from it, offers 1.5" of resistance over the 100 foot tested. That is 375Pa of resistance, which some of the fans spoke of, perhaps couldn't do. That's even before adding the filter, and using 4" not 6" ducting. Okay, 100 foot is long, but it's a straight run of 6". On that graph we also see the 6" draped over rafters at 2' intervals. Between them, it's allowed to sag a couple of inches, like a run over insulation. This means 4" of our 6" duct is straight still, but the loss is like 650pa, which is troubling a centrifugal fan, without filter. Only the EC motor powered centrifugal fan could overcome a 4" filter and 100 foot of 6" load loose through the roof.

We have not even got to bends yet. Typically an installation isn't allowed more than 2 bends, and the minimum bending angle, is like going around itself. For example, a 6" duct should turn as tight as a 6" paint can allows. Not a tent pole.

The take home from this, is that many of us are spinning our fans far to loud, and getting nowhere, because our duct run is foul. Coupled to the fans they like selling us, with a filter, it's a wonder things work at all sometimes.

I was looking at a 12" fan, going out a chimney last week. I have been trying to explain to them that the pot is about 8". That they need something with some real shove behind it. However, they just understand cfm.

Incidentally, I took a tiny pump around that would beat their well pump, but they didn't even try it. Bigger is better... at waking the neighbours, if nothing else.

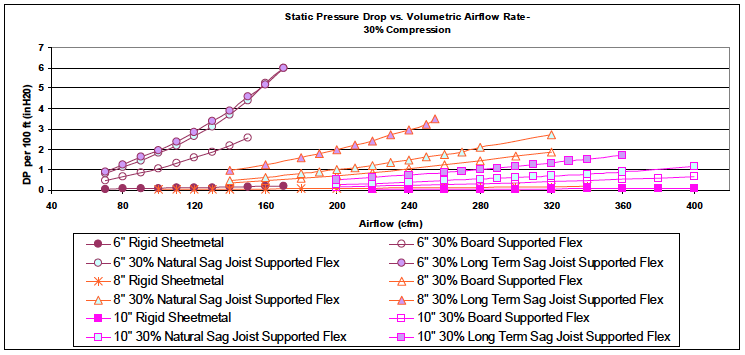

Here is a pic from the link

Fully stretched flexi is very similar to metal tube. We were looking at 4" carbons, which typically scrub about 200m2/h or 120cfm for this graph. We don't have 4" tested, but the 6" results speak loudly. So 6" laid out on a solid surface, pulled out to the point that you could get maybe half again from it, offers 1.5" of resistance over the 100 foot tested. That is 375Pa of resistance, which some of the fans spoke of, perhaps couldn't do. That's even before adding the filter, and using 4" not 6" ducting. Okay, 100 foot is long, but it's a straight run of 6". On that graph we also see the 6" draped over rafters at 2' intervals. Between them, it's allowed to sag a couple of inches, like a run over insulation. This means 4" of our 6" duct is straight still, but the loss is like 650pa, which is troubling a centrifugal fan, without filter. Only the EC motor powered centrifugal fan could overcome a 4" filter and 100 foot of 6" load loose through the roof.

We have not even got to bends yet. Typically an installation isn't allowed more than 2 bends, and the minimum bending angle, is like going around itself. For example, a 6" duct should turn as tight as a 6" paint can allows. Not a tent pole.

The take home from this, is that many of us are spinning our fans far to loud, and getting nowhere, because our duct run is foul. Coupled to the fans they like selling us, with a filter, it's a wonder things work at all sometimes.

I was looking at a 12" fan, going out a chimney last week. I have been trying to explain to them that the pot is about 8". That they need something with some real shove behind it. However, they just understand cfm.

Incidentally, I took a tiny pump around that would beat their well pump, but they didn't even try it. Bigger is better... at waking the neighbours, if nothing else.