refriedbeano

New member

This is my third season growing outdoors. I've been building out on public land next to a dam, since last year I've been harassed by the water authority, the head of security of this organization has found all my "sites" so I'm going to have to build a new one when the seedlings mature up.

I've been designing and testing some new machines to automatically dry and cure marijuana, called the budcure box and cannaster. They are needing some attention but I still have allot of time to work on them.

Right now I just got the seeds in and I'm almost ready to get into gardening mode. I have to glue down the cloche greenhouse that i have to some foam board because last year ants ate my seedlings. I haven't seen any around but you never know. The type of marijuana is called grandaddy purple Autoflower seeds, from ILGM, but I've noticed that the phenotype is all over the place with this company, so it might not even matter what they are. But I got 20 of them, and plane to start small and plant only two of them, then keep on planting as i move them out of the cloche.

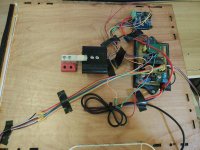

For the BudCure Box I have to CNC a new PCB because I have had nothing but problems trying to get the relay or mosfet switches to actually work. It takes so much to CNC the board, put all the components on it, make sure it all works only to find it didn't. But other than that i just have to install a fan and its ready to dry.

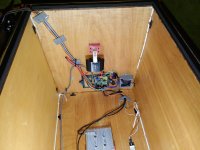

For the Cannaster (the machine inside the BudCure Box) the lid isn't designed right and it doesn't let the pressure get down enough to dry the plant material. I have to redesign the lid and gasket to try and improve on that, because in the enclosed space the buds will grow mold in only half a day. But the whole purpose of the Cannaster is to get the bud to the perfect 63% rh so you can throw it in a mason jar and store it away, without burping it.

I've been designing and testing some new machines to automatically dry and cure marijuana, called the budcure box and cannaster. They are needing some attention but I still have allot of time to work on them.

Right now I just got the seeds in and I'm almost ready to get into gardening mode. I have to glue down the cloche greenhouse that i have to some foam board because last year ants ate my seedlings. I haven't seen any around but you never know. The type of marijuana is called grandaddy purple Autoflower seeds, from ILGM, but I've noticed that the phenotype is all over the place with this company, so it might not even matter what they are. But I got 20 of them, and plane to start small and plant only two of them, then keep on planting as i move them out of the cloche.

For the BudCure Box I have to CNC a new PCB because I have had nothing but problems trying to get the relay or mosfet switches to actually work. It takes so much to CNC the board, put all the components on it, make sure it all works only to find it didn't. But other than that i just have to install a fan and its ready to dry.

For the Cannaster (the machine inside the BudCure Box) the lid isn't designed right and it doesn't let the pressure get down enough to dry the plant material. I have to redesign the lid and gasket to try and improve on that, because in the enclosed space the buds will grow mold in only half a day. But the whole purpose of the Cannaster is to get the bud to the perfect 63% rh so you can throw it in a mason jar and store it away, without burping it.