Off the shelf retail store screw-in LED and CFL bulb comparisons

- Thread starter Thread starter blynx

- Start date Start date

NIKT

Active member

Another interesting project from the F#

by: R4VEN

One of the most interesting tutorials I've ever seen. Developed very well. It's a pity that something similar wasn't shown 4 years ago, when the efficiency ratio of e27 to commercial panels was much better. This panel probably has an efficiency slightly above what the TS 600 offers.

Similarly built mod with a 9.5 W solhetta could have power adjustments and efficiency perhaps around 2.4 or more. (If we take the test of this source on the Russian website lamptest.ru at face value, then with the SPD shown there and the efficiency after deprivation of distractions, it may be slightly above 2.5??)

forum.haszysz.com

forum.haszysz.com

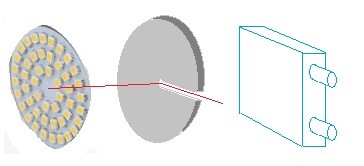

From development in the CAD program

to report on the implementation of the project with instructions

by: R4VEN

One of the most interesting tutorials I've ever seen. Developed very well. It's a pity that something similar wasn't shown 4 years ago, when the efficiency ratio of e27 to commercial panels was much better. This panel probably has an efficiency slightly above what the TS 600 offers.

Similarly built mod with a 9.5 W solhetta could have power adjustments and efficiency perhaps around 2.4 or more. (If we take the test of this source on the Russian website lamptest.ru at face value, then with the SPD shown there and the efficiency after deprivation of distractions, it may be slightly above 2.5??)

[TUTORIAL] Żyrandolled na profilach: destrukcja lamp - 6x LSC

1. WSTĘP ORAZ PODZIĘKOWANIA Na forum znajduje się dużo poradników budowy podobnych konstrukcji, jednak trzeba być dobrym górnikiem aby dokopać się do złota (istotnych informacji). Dla tych, którzy tak jak ja nie studiowali optyki czy mają duży problem w odnalezieniu się wśród dziesiątek...

From development in the CAD program

to report on the implementation of the project with instructions

|

|

|

|

|

|

|

|

Haha bump!

I wonder if there is a way to drill a small hole (or start a crack at the seams) into the plastic housing, and blast it away from the aluminum shell with a compressed air nozzle. Something quicker than spending 2 minutes grinding and hacking at it with a dremel..

I thought of a "cool" idea for SILs. A liquid cool that is..

So. Eventually, when the diodes have all burned out on enough of your bulbs.. you could cut away the aluminum can shell areas on all the bulbs like NIKT does ^, like a smaller ring section. Then, wrap each one with a copper tubing coil, and braze it in place. Now you have custom screw in LED bulb water cooling jackets that can slip right over the aluminum shell on the new bulbs!

Simply remove the plastic off the new bulbs (that are the same model of course), and slip the custom cooling coil jackets right over the new ones aluminum shells, and connect them all with some clear tubing and clamps. Hook up a water cooling pump/reservoir/radiator kit remotely outside of the grow (or on the same fixture), and the new bulbs should last quite a long time!

I'll take a picture to show what I mean. Because the aluminum housings are tapered, one will fit right over the other. Could even dab a little bit of thermal compound in between for better transfer of heat.

I been wondering how to actually water cool SILs cheaply for a long time now, and the idea hit me on how to do it. By using old dead bulbs to make the water blocks.

I wonder if there is a way to drill a small hole (or start a crack at the seams) into the plastic housing, and blast it away from the aluminum shell with a compressed air nozzle. Something quicker than spending 2 minutes grinding and hacking at it with a dremel..

I thought of a "cool" idea for SILs. A liquid cool that is..

So. Eventually, when the diodes have all burned out on enough of your bulbs.. you could cut away the aluminum can shell areas on all the bulbs like NIKT does ^, like a smaller ring section. Then, wrap each one with a copper tubing coil, and braze it in place. Now you have custom screw in LED bulb water cooling jackets that can slip right over the aluminum shell on the new bulbs!

Simply remove the plastic off the new bulbs (that are the same model of course), and slip the custom cooling coil jackets right over the new ones aluminum shells, and connect them all with some clear tubing and clamps. Hook up a water cooling pump/reservoir/radiator kit remotely outside of the grow (or on the same fixture), and the new bulbs should last quite a long time!

I'll take a picture to show what I mean. Because the aluminum housings are tapered, one will fit right over the other. Could even dab a little bit of thermal compound in between for better transfer of heat.

I been wondering how to actually water cool SILs cheaply for a long time now, and the idea hit me on how to do it. By using old dead bulbs to make the water blocks.

Ca++

Well-known member

Maybe?

With the EU energy rating of 'A' demanding over 210lm/w, the e27 isn't dead yet.

Every name I know for a lamp, links to every other. Non link to 'sil' though, and a direct search doesn't help. Where is this naming convention coming from? To me, it's a chip packaging.

With the EU energy rating of 'A' demanding over 210lm/w, the e27 isn't dead yet.

Every name I know for a lamp, links to every other. Non link to 'sil' though, and a direct search doesn't help. Where is this naming convention coming from? To me, it's a chip packaging.

Maybe, but the cost of using pre-made water blocks would add up quickly. I want to get the cost down to less than a dollar per bulb, if not free using scrap metals. I'm thinking it would be easiest to cut away a ring section the plastic, and wrap one or 2 turns of cheap aluminum brake line or some other tubing (3/8" or bigger diameter for better flow if possible) tightly around the exposed aluminum shell of the bulb, and braze it in place. That would be so cheap I wouldn't care about trying to re use it later if the bulb burns out. Even if it did I could just swap either the bad driver or the PCB with diodes with new ones from a new bulb right back over into the old water cooled bulb housings, without having to re do anything. Then again, there would be little surface contact from the round tubing not toughing as good, but should be good enough to transfer most of the heat, especially if you get a good weld all the way around without melting holes through the bulb..

Ca++

Well-known member

Commercial water blocks are about $2.50

They are just a sandwich of 3 layers. The bread is just thin plain stuff, but the filling is a bit more interesting. People use copper, and bake them to make the solder run.

The filling could be heavy plate, with channels cut out, but machining that at home is probably a lot to ask. You could use strips to build individual walls, for the water maze.

You could move the idea along, and make the sandwich with one copper slice, and the rest in plastic. Fish tanks have no problem being assembled with silicone. The plastic offers some heat insulation. Insulation would play a big part, as the heat from the lamps isn't that much, and a big water system will loose that heat without needing a specific radiator.

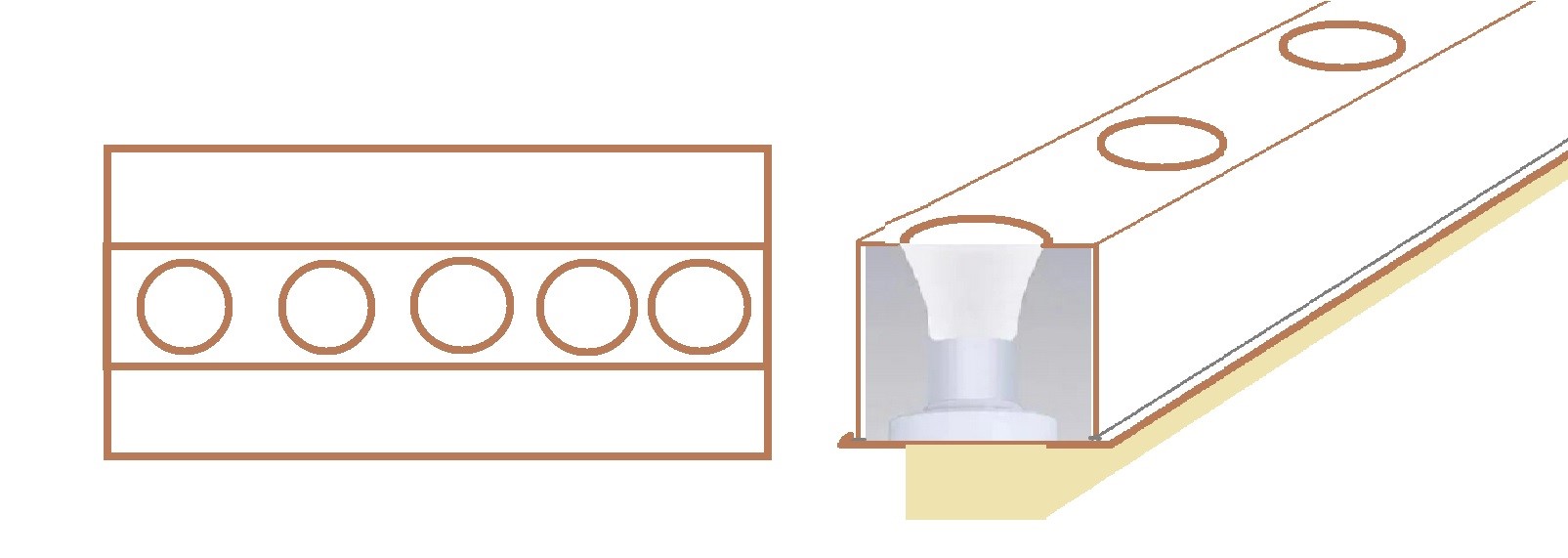

It might be very easy to just buy bits of square section tube. Maybe 2x1 and be done with it. One length with lights among it. Or you could use 10mm box section, and lay them side by side. It would be easy to block the ends, and drill through the sides where they are stuck together. Making 10mm water channels, that suit the expected pump.

I'm not sure, but while the LED is 50mm wide, and the spacer I sketched out also 50mm, I'm not sure that the water element needs to be that wide. I think a bit of 10x20mm box would probably be enough, and such a six box makes pipe lagging an option.

It's good to talk, but I need my first coffee, and to aim my brain at fixing the car

They are just a sandwich of 3 layers. The bread is just thin plain stuff, but the filling is a bit more interesting. People use copper, and bake them to make the solder run.

The filling could be heavy plate, with channels cut out, but machining that at home is probably a lot to ask. You could use strips to build individual walls, for the water maze.

You could move the idea along, and make the sandwich with one copper slice, and the rest in plastic. Fish tanks have no problem being assembled with silicone. The plastic offers some heat insulation. Insulation would play a big part, as the heat from the lamps isn't that much, and a big water system will loose that heat without needing a specific radiator.

It might be very easy to just buy bits of square section tube. Maybe 2x1 and be done with it. One length with lights among it. Or you could use 10mm box section, and lay them side by side. It would be easy to block the ends, and drill through the sides where they are stuck together. Making 10mm water channels, that suit the expected pump.

I'm not sure, but while the LED is 50mm wide, and the spacer I sketched out also 50mm, I'm not sure that the water element needs to be that wide. I think a bit of 10x20mm box would probably be enough, and such a six box makes pipe lagging an option.

It's good to talk, but I need my first coffee, and to aim my brain at fixing the car

Last edited:

Ca++

Well-known member

I had another look. A foot long block is $10 and might hold 6.

A 100w equivalent can be 9.5w now. Over half is heat, but it's still a small amount of heat that can be removed. Even with decent insulation. Which is a difficulty coiling soft copper around a lamp.

If it's strictly a water cooling project, then some cobs on that $10 block would make use of it. With these GLS lamps, air cooling is a lot easier. You need some 60x110 duct (its a standard) then put the lamps inside it, pointing out though holes you cut. This keeps the hot bit in the duct.

A 100w equivalent can be 9.5w now. Over half is heat, but it's still a small amount of heat that can be removed. Even with decent insulation. Which is a difficulty coiling soft copper around a lamp.

If it's strictly a water cooling project, then some cobs on that $10 block would make use of it. With these GLS lamps, air cooling is a lot easier. You need some 60x110 duct (its a standard) then put the lamps inside it, pointing out though holes you cut. This keeps the hot bit in the duct.

Ca++

Well-known member

If you have lamps and holders already, you could screw the holders to a wooden lat, pinching some card between them. Then fab a cover to go over the lamps and glue to the trapped bit. There are some concerns towards fire safety, but it would be easy to mock up, as a trial.

The real safety concern, is mounting baton lamp holders to combustible material. Poor wiring methods are somewhat unavoidable, as the batons offer no cord grip. So you would need to tie wrap the flex to the wood, even just running it for a test. If a wire got pulled out.. sparks are almost certain.

Making this good, would probably involve cable trunking. Galvanised or flame extinguishing plastic. With plastic being very easy to work with. Plus insulating.

If I can find it..

Hot bits in trunking, looking out

The real safety concern, is mounting baton lamp holders to combustible material. Poor wiring methods are somewhat unavoidable, as the batons offer no cord grip. So you would need to tie wrap the flex to the wood, even just running it for a test. If a wire got pulled out.. sparks are almost certain.

Making this good, would probably involve cable trunking. Galvanised or flame extinguishing plastic. With plastic being very easy to work with. Plus insulating.

If I can find it..

Hot bits in trunking, looking out

I need 100 water blocks, so spending more than a buck per block is out of the question. I also want to keep the bulbs spread out, and have one block per bulb. Don't really wanna try and stuff as many chips as I can per block so close together..

I do like the idea of plugging the ends of a long square tube and pumping through it, and the fact it can be part of the actual frame, but the cost would be ridiculous just for cooling cheap SILS, unless I can score the square tubing at scrap prices. I know we've talked about it many times in this thread over the years, and how to pull it off.. Now I'm ready to actually do it, and the price of everything aluminum or copper practically doubled. Figures, lol..

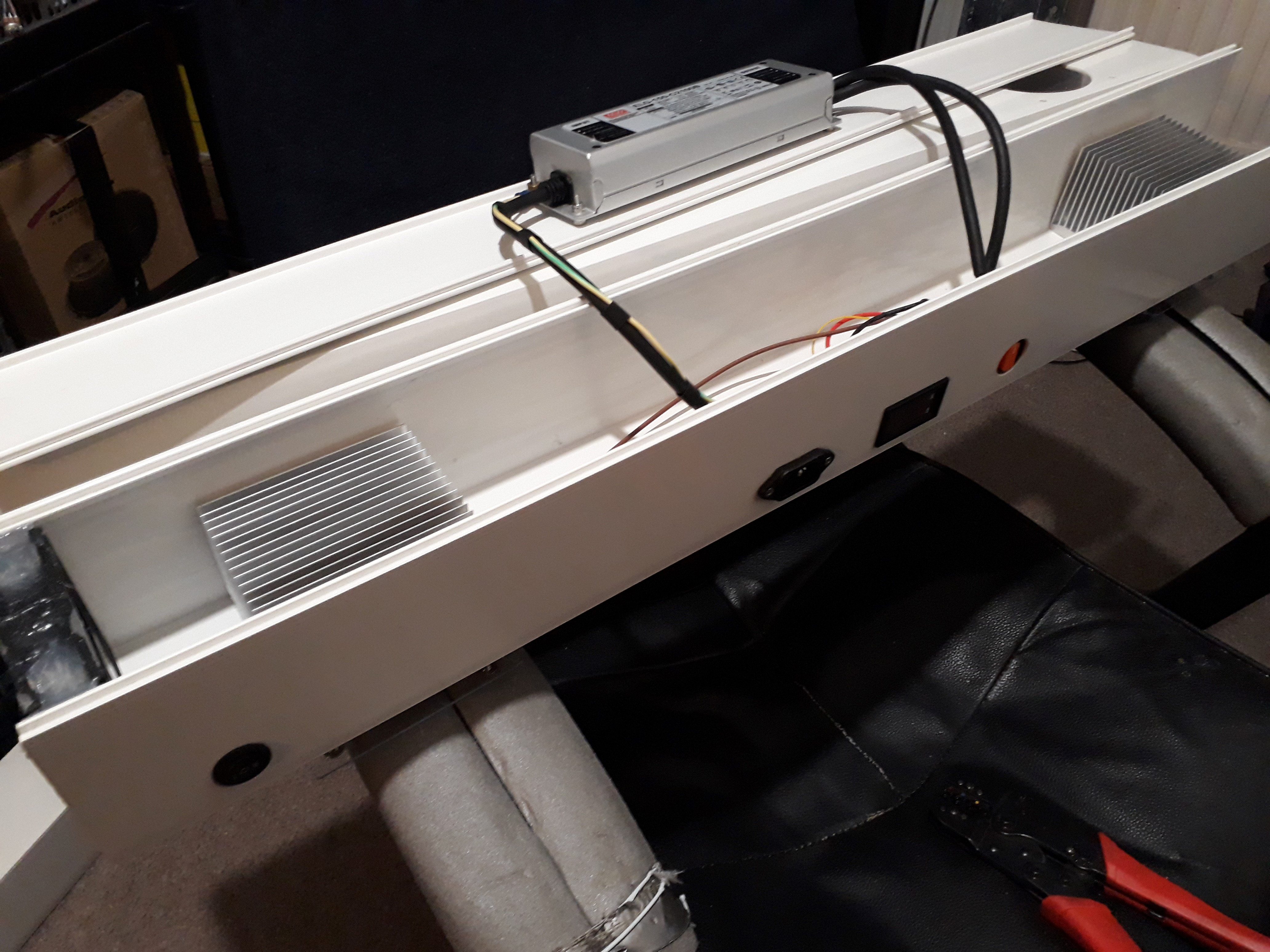

I got to looking at the great value walmart brand bulbs I have, and the metal "cattle prod taser" prongs that connect the driver to the PCB are actually long enough that it would allow me to sandwich an 1/8" thick aluminum plate right in between them as is, and just use 1/8" longer screws to hold it together. I could simply drill a hole for the prods to go through, and not have to do any wiring mods. There is already thermal compound as well, so no extra needed.

My new idea, is to buy an 8 ft long 2 inch wide aluminum flat bar (cheap as possible), and cut it into 2x2" plates. Then, use alumaweld brazing rods from harbor freight with a propane\map torch to weld 3" or so long pieces of 3/8" aluminum tubing to right to the side of the flat aluminum pieces, so the ends stick out long enough from each side to clamp some plastic tubing onto. I might even grind a radius on one or 2 sides of the flat pieces, so I can bend the tubing around the plate with angles, and help to slightly restrict the flow for maximum heat abortion.

I'll make up the DIY prototype SIL water cooling block soon, and test it out before buying enough materials to make 100s of them. Also gonna test out just wrapping the tubing right around the exposed aluminum section of the bulb, and brazing it in place with the same alumaweld rods. I'll use my temp gun and record the results while hooked up to a PC water cooling rad/res/pump kit.

Be back with pics soon.

I do like the idea of plugging the ends of a long square tube and pumping through it, and the fact it can be part of the actual frame, but the cost would be ridiculous just for cooling cheap SILS, unless I can score the square tubing at scrap prices. I know we've talked about it many times in this thread over the years, and how to pull it off.. Now I'm ready to actually do it, and the price of everything aluminum or copper practically doubled. Figures, lol..

I got to looking at the great value walmart brand bulbs I have, and the metal "cattle prod taser" prongs that connect the driver to the PCB are actually long enough that it would allow me to sandwich an 1/8" thick aluminum plate right in between them as is, and just use 1/8" longer screws to hold it together. I could simply drill a hole for the prods to go through, and not have to do any wiring mods. There is already thermal compound as well, so no extra needed.

My new idea, is to buy an 8 ft long 2 inch wide aluminum flat bar (cheap as possible), and cut it into 2x2" plates. Then, use alumaweld brazing rods from harbor freight with a propane\map torch to weld 3" or so long pieces of 3/8" aluminum tubing to right to the side of the flat aluminum pieces, so the ends stick out long enough from each side to clamp some plastic tubing onto. I might even grind a radius on one or 2 sides of the flat pieces, so I can bend the tubing around the plate with angles, and help to slightly restrict the flow for maximum heat abortion.

I'll make up the DIY prototype SIL water cooling block soon, and test it out before buying enough materials to make 100s of them. Also gonna test out just wrapping the tubing right around the exposed aluminum section of the bulb, and brazing it in place with the same alumaweld rods. I'll use my temp gun and record the results while hooked up to a PC water cooling rad/res/pump kit.

Be back with pics soon.

Here is what I’m talking about. I won’t need any extra wires or shims or anything, just cheap aluminum flatbar and tubing, that I hack up and weld together with brazing rods. I think I can pull it off for less than 50 cents per block. I don’t care if my diy water plates aren't as efficient as a cross drilled block, but who knows maybe they actually will work better!? If they work at all. Ill let you guys know what I come up with...

Heres some pics of a mockup. Imagine the white wire and cardboard are aluminum instead.

I think the extra length of tubing with bends will help..

Usually you want to bevel the edges of aluminum plating before welding with rods, but the tubing already creates the capillary gap needed for my water exchange plates. I should be able to blast through a pile in no time! Hopefully not right through the plates or the tubes though, I'll have to be real careful not to get it too hot and melt it or warp the plates.

Some guys practice using the alumiweld rods on thin beer cans, so I don't see a problem trying to weld pipe to 1/8" thick plates.

Some guys practice using the alumiweld rods on thin beer cans, so I don't see a problem trying to weld pipe to 1/8" thick plates.

Gonna pickup what I need and try it soon.

One more pic showing the gap I’m working with.

One more pic showing the gap I’m working with.

Last edited:

Ca++

Well-known member

Your certainly moving this along

Remember you can't bend alloy pipe. Even stuffed with sand, it just cracks. It also needs an additive in the water.

I like the edge cooling. I would be tempted to do two opposite edges. So the entire assembly of a row of lights, looks a bit like a ladder for action man. The edge cooling means heat moves away from the LEDs by the nearest route. If you just do one edge, the heat from the farthest LEDs must pass all the others before it gets to leave. Doing opposite edges gets the heat straight out, and the ladder arrangement offers a structural gain. While water movement will be better, and insulation off the shelf.

You might have 700w? to move out. I think PC kits are expecting 100w. You may end up at the breakers, looking at a car heater matrix. Or two. The cooler the water, the more the heat will move towards it. So you want it around your loop and back to the radiator, as quickly as possible. Long straight runs could achieve this.

Is there any hope of using copper plate, not alloy? They have a thermal conductivity of 401 and 237 respectively. Making copper about 70% better. That could make a real difference to your project.

I tried them alloy rods once. I made up some hardpipe's for my turbo conversion. They looked great, until I doused the work. They literally washed off. Many more tries, with different flux (that shouldn't be needed) and enough different temperatures that the alloy was showing fatigue, I gave up. The rods never showed the slightest of interest. Give me copper and solder every time. Something with lead metal in it. It's very rare I walk away, but them rods and my alloy pipe, were never going together. Alloy needs a decent welder.

Edit: As one of my few fails, I have not let this go. I just watched a few videos again, and even the one's saying it's good, didn't look it to me. They got it to stick, but like the video above, it's not flowed. It's beading. In this instance you want a thin plate to have maximum contact with the tube, so you need your filler to flow, not bead.

Remember to ground this metalwork, and some earth leakage detection breakers are very much needed. The drivers are current limiting, so a fuse for short circuit protection, isn't going to trip. You should have a breaker looking for earth leakage, and as it's a wet room, you need something like 15mA not 30mA. If your in a tool shop with 100mA detection, then that breaker won't see the expected current from them lamps.

My breaker ratings revolve around UK approvals. Your breaker choices may be different.

Remember you can't bend alloy pipe. Even stuffed with sand, it just cracks. It also needs an additive in the water.

I like the edge cooling. I would be tempted to do two opposite edges. So the entire assembly of a row of lights, looks a bit like a ladder for action man. The edge cooling means heat moves away from the LEDs by the nearest route. If you just do one edge, the heat from the farthest LEDs must pass all the others before it gets to leave. Doing opposite edges gets the heat straight out, and the ladder arrangement offers a structural gain. While water movement will be better, and insulation off the shelf.

You might have 700w? to move out. I think PC kits are expecting 100w. You may end up at the breakers, looking at a car heater matrix. Or two. The cooler the water, the more the heat will move towards it. So you want it around your loop and back to the radiator, as quickly as possible. Long straight runs could achieve this.

Is there any hope of using copper plate, not alloy? They have a thermal conductivity of 401 and 237 respectively. Making copper about 70% better. That could make a real difference to your project.

I tried them alloy rods once. I made up some hardpipe's for my turbo conversion. They looked great, until I doused the work. They literally washed off. Many more tries, with different flux (that shouldn't be needed) and enough different temperatures that the alloy was showing fatigue, I gave up. The rods never showed the slightest of interest. Give me copper and solder every time. Something with lead metal in it. It's very rare I walk away, but them rods and my alloy pipe, were never going together. Alloy needs a decent welder.

Edit: As one of my few fails, I have not let this go. I just watched a few videos again, and even the one's saying it's good, didn't look it to me. They got it to stick, but like the video above, it's not flowed. It's beading. In this instance you want a thin plate to have maximum contact with the tube, so you need your filler to flow, not bead.

Remember to ground this metalwork, and some earth leakage detection breakers are very much needed. The drivers are current limiting, so a fuse for short circuit protection, isn't going to trip. You should have a breaker looking for earth leakage, and as it's a wet room, you need something like 15mA not 30mA. If your in a tool shop with 100mA detection, then that breaker won't see the expected current from them lamps.

My breaker ratings revolve around UK approvals. Your breaker choices may be different.

Last edited:

Yeah I was just gonna use the PC kit (120mm copper radiator & fan) for the test on one or 2 bulbs, with and without and record the temps. I will for sure be using bigger radiators to cool the 740+ watt fixtures. Heater cores from some of my scrap vehicles for sure, lol.

The reason I want to use aluminum, is because its so cheap, and also the rest of the parts will be aluminum too, including the radiators. I don't want to mix copper and aluminum in the cooling loop and risk galvanic corrosion. I'll be filling it with UV reactive coolant, and want it to stay looking nice

If I use copper plate and tubing for the water blocks, I must use a copper radiator too, etc. The price will double or triple.

I did think of adding another section of tubing on the other side of the plate, and splitting the flow with Y-fittings on each side, but it sounds pretty redundant..

Perhaps I could cut 45 degree angles and weld the tubing to get my 90 degree bends.

I do have a nice wire feed welder, but haven't got the aluminum spool gun for it yet. I almost feel it would be over kill for this project. I'm not trying to hold pressure or seal leaks, just connect parts for transfer of heat.

I see coils of aluminum tubing that is already pre-coiled shape, and made for custom brake lines.. I was gonna try that kind over the straight tubes..

The reason I want to use aluminum, is because its so cheap, and also the rest of the parts will be aluminum too, including the radiators. I don't want to mix copper and aluminum in the cooling loop and risk galvanic corrosion. I'll be filling it with UV reactive coolant, and want it to stay looking nice

If I use copper plate and tubing for the water blocks, I must use a copper radiator too, etc. The price will double or triple.

I did think of adding another section of tubing on the other side of the plate, and splitting the flow with Y-fittings on each side, but it sounds pretty redundant..

Perhaps I could cut 45 degree angles and weld the tubing to get my 90 degree bends.

I do have a nice wire feed welder, but haven't got the aluminum spool gun for it yet. I almost feel it would be over kill for this project. I'm not trying to hold pressure or seal leaks, just connect parts for transfer of heat.

I see coils of aluminum tubing that is already pre-coiled shape, and made for custom brake lines.. I was gonna try that kind over the straight tubes..

Here is the aluminum tubing I was talking about. the kind that is made to bend, and be used as brake/fuel lines, or refrigeration components, etc. 3003 grade, for low psi applications.

I could do 3 bends, and go almost all the way around the plates.. Not sure, but I'll come up with something that works, and pulls the heat from at least both sides, if not all the way around.

I think the basic idea of the edge piping around the plates to use as water blocks will work just fine though!

They did similar things with cell phone cooling systems, but they would flatten the tubing before attaching to the plate.. And used copper, because they aren't cheapskates like me

I could do 3 bends, and go almost all the way around the plates.. Not sure, but I'll come up with something that works, and pulls the heat from at least both sides, if not all the way around.

I think the basic idea of the edge piping around the plates to use as water blocks will work just fine though!

They did similar things with cell phone cooling systems, but they would flatten the tubing before attaching to the plate.. And used copper, because they aren't cheapskates like me

I would be a fool to go through all the trouble and not just use copper.. and spend a little extra. It will be so much easier to work with, and as you say more than double the ability to transfer heat. Dang it! Ok I will use copper..

Ca++

Well-known member

Most of the heater/aircon units I have seen, are copper cored. The fins are alloy, but not the pipes. Though I wouldn't worry about mixed metals, if you have a corrosion inhibitor.

Coolant is an odd thing. It doesn't keep the engine cool. It keeps the water cool. It's job is to stop rapid heat transfer to the water, that could create steam. It gives an overall loss of system efficiency, in systems that can function without it. Oddly my 8v golf(rabbit?) was fine without, but my 16v needed it, or it would airlock with steam. The water just didn't circulate around the head well enough.

Why are they cooling their phones anyway lol

I see copper is twice the price, but do you have any 'reclaim' options?

Perhaps a building coming down, or an actual reclaim yard that might help you out?

Having 1/2" runs makes a structure you can hang them by. I looked at soft copper and such, but the pipe bores were small to be pumping through, and don't offer that framework. I think you are really onto something with the edge cooled plates, that long pipes would hold together as a single unit. The cost though... it's not cheap. A good reclaim yard might get it though, and the lagging.

Coolant is an odd thing. It doesn't keep the engine cool. It keeps the water cool. It's job is to stop rapid heat transfer to the water, that could create steam. It gives an overall loss of system efficiency, in systems that can function without it. Oddly my 8v golf(rabbit?) was fine without, but my 16v needed it, or it would airlock with steam. The water just didn't circulate around the head well enough.

Why are they cooling their phones anyway lol

I see copper is twice the price, but do you have any 'reclaim' options?

Perhaps a building coming down, or an actual reclaim yard that might help you out?

Having 1/2" runs makes a structure you can hang them by. I looked at soft copper and such, but the pipe bores were small to be pumping through, and don't offer that framework. I think you are really onto something with the edge cooled plates, that long pipes would hold together as a single unit. The cost though... it's not cheap. A good reclaim yard might get it though, and the lagging.

With that style, you wouldn't need base sockets to hold the bulbs. You could pull the ends off and wire them in, and save almost enough money for the tubing and plates, lol.

I already have 100s of lamp sockets though, so it will be cheaper to make a frame, and seperate the water cooling plates individually like the first design I posted...

I already have 100s of lamp sockets though, so it will be cheaper to make a frame, and seperate the water cooling plates individually like the first design I posted...