-

ICMag with help from Landrace Warden and The Vault is running a NEW contest in November! You can check it here. Prizes are seeds & forum premium access. Come join in!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New England Growers and Medical Users

- Thread starter FatBlunt420

- Start date

well again, its more of a bare bulbs grow. and there will be plenty of light... i expect it to work out just fine.

G

Ganja D

I remember that article. The concept is basically when half the lights are off it's like a portion of your room is experiencing the same thing as a cloudy day.I remember reading an article in hightimes years ago about dutch growers staggering lights in a similar way to how FB is doing. They managed to get virtually the same yields while using half as much power, wicked smart!!

good luck bro!!

I remember that article. The concept is basically when half the lights are off it's like a portion of your room is experiencing the same thing as a cloudy day.

yes sir, and with more hoods close together there is plenty of light.

its a new/different idea i had, only time will tell if it works out as planned.

-=-

i got post 1,666 here too...

Last edited:

E

emerald city

Ive seen the stagered lite design on a large scale[warehouse] type grow,never thought of it applying to a smaller footprint..After rethinking the therory,ive noticed a friend doing good work running duel 600's over a 4x8 areaim glad you all get it. its a totally different set up, that ive never seen done before, all the light will be there. and i like trying somthing new.

E.C. you must be over your head in water right now!! that rain last night was BRUTAL. im glad it cleared all the snow tho. (now the drive ways clear and i can leave the house.)

,where i would be inclined to run 2 1000's.

If you come up with a way to save money on the electric bill im all for it....good luck.

Later gang

off to finish the day..

off to finish the day..

E

emerald city

As of now, the area in which we reside recieved aprox 4" of rain...

Last night as im lying in bed listening to the wind driven rain beating against the windows,the wife asks just before i nod off"do you think your water pumping system will hold the nite? this time ?? "..."Forgettabouttit" i say , for the first time in many storms I sleep like a baby through the nite.....Of course the first order of business this am was to check for storm damage, to make sure the storm hadnt disrupted power supplys[timers etc] and then to check on the dreaded"perpetually" flooding room and see if the water was being held at bay[more like a La-goon at times]..As i rounded the back of the building i could see directly in front of my discharge pipe i was creating a pond in the dog kennel area and had washed all the straw bedding down stream.....Atleast im moving water im thinking,as i head underground...

Much to my surprize my homemade water recovery system has worked through out the nite and is keeping up with the riseing tides....Found one pinhole leak towards the end of the line and promptly covered with duct tape..This plastic flex pipe im useing isnt ment to be under the presure that the pump is putting on it..Probly have to break down and buy expensive radiator hose in the long term instead of going the perminate black pvc....So far so good..Still makes me nervous removing hundreds of gallons of h2o in 1 1/2 plastic hose directly over electrical equipment.. Thanks for the concern gAng ,on to the holidaze

Thanks for the concern gAng ,on to the holidaze

If it gonna be winter,let the ground freeze and let it snow...

Back to growing not groaning

Last night as im lying in bed listening to the wind driven rain beating against the windows,the wife asks just before i nod off"do you think your water pumping system will hold the nite? this time ?? "..."Forgettabouttit" i say , for the first time in many storms I sleep like a baby through the nite.....Of course the first order of business this am was to check for storm damage, to make sure the storm hadnt disrupted power supplys[timers etc] and then to check on the dreaded"perpetually" flooding room and see if the water was being held at bay[more like a La-goon at times]..As i rounded the back of the building i could see directly in front of my discharge pipe i was creating a pond in the dog kennel area and had washed all the straw bedding down stream.....Atleast im moving water im thinking,as i head underground...

Much to my surprize my homemade water recovery system has worked through out the nite and is keeping up with the riseing tides....Found one pinhole leak towards the end of the line and promptly covered with duct tape..This plastic flex pipe im useing isnt ment to be under the presure that the pump is putting on it..Probly have to break down and buy expensive radiator hose in the long term instead of going the perminate black pvc....So far so good..Still makes me nervous removing hundreds of gallons of h2o in 1 1/2 plastic hose directly over electrical equipment..

Thanks for the concern gAng ,on to the holidaze

Thanks for the concern gAng ,on to the holidaze

If it gonna be winter,let the ground freeze and let it snow...

Back to growing not groaning

Amber Trich

Active member

Yield of Dreams by Jorge Cervantes

Yield of Dreams by Jorge Cervantes

This will be FatBlunt420....

Yield of Dreams by Jorge Cervantes

This will be FatBlunt420....

YIELD OF DREAMS

Using half the normal light, you can reduce growroom temps and electrical bills and achieve a healthy and heavy harvest.

by Jorge Cervantes

"You can use half the light and achieve the same harvest," says James, an astute man with a cat-that-ate-the-canary look, as he puffs on a spLiff the size of a big Cuban cigar.

"You're joking," I wince, "but I'll hear you out if you pass me that spliff."

After a short conversation, during which he makes a few simple growroom drawings on the back of a brochure, I'm convinced he's on to something very, very interesting. "This looks good on paper and sounds too good to be true," I say. "I must see proof before sharing this with High Times'Grow America readers. They are a very demanding Lot."

James whips out his cell phone and quickLy makes four appointments for the following two days with growers in southern Holland.

We meet the next morning, have coffee, a few tokes of Snowball, and jump into a panel delivery truck packed with electrical and hydroponics supplies. We pull into a typical Dutch driveway and disappear behind an automatic garage door. The home looks no different than any other in the neighborhood, until we climb the stairs to Mr. Clean's attic growroom.

"Heat is a big problem here, because the growroorn is just below the roof," James explains. "We had to do something to keep the room cool but not use any more electricity. What we found costs less and works better." With a twinkle in his eye, he continues: "When the temperatures rise outdoors, it's more difficult to control the microclimate in the room.

Air circulation changes. Convection becomes more intense. Humidity, water absorption, and evaporation speed up as well."

High-intensity-discharge lights generate heat that can cause many problems in a growroom. For the best results, the average temperature should stay around 75*F during the day and no less than 55*F at night. Daytime growroom temperatures as high as 90*F can cause irregular nutrient uptake and slow growth.

"On average, a hot system will produce between 35% and 60% less than a system running at nominal temperatures," says James. "The other problem is that the buds don't close. They stay fluffy. THC levels are also lower when plants are grown hot. And you have the extra work of trimming these fluffy bastards."

The fluffy buds are less-than-prime smoke and fetch a lower market price. High temperatures also cause buds to exude more pungent odors, which could alert neighbors to the grow operation.

To avoid these problems, James started experimenting with schedules in the flowering rooms, where the light regimen was set at 12 hours on and 12 hours off. He tried turning half the lights on for the first hour of the day before switching on the other half. Then he tried turning half the lights off for the last hour of the day.

"We noticed no real difference in growth or production, and we were saving a few kilowatt hours of electricity," James says. "But we still didn't solve our heat and odor problems. That's when I got radical and put my engineering background to use."

James spent 14 years as an engineer for Grodan, a Danish soil company. Most of those years, he visited greenhouses in the Netherlands solving problems. They still call "Witty Wortel," Dutch for "problem solver."

"You know about the two Dutch guys who invented copper wire, right?" inquires James. I answer with a blank stare. "Yes, they were fighting over a penny! We've found a new invention that makes the same penny twice as valuable as it was before."

James evaluated the data he'd amassed over the years spent troubleshooting in the greenhouse industry and found that plants need bright light, but react slowly to it. Greenhouses are dependent upon natural sunlight. Artificial Light is used when natural light intensity levels drop below a specific point. Different plants require different light levels. When plants are given less artificial they react as though growing in shade; they mature more slowly and lack vigor. James wondered what would happen if he simulated the greenhouse environment indoors.

In the Netherlands, direct sunshine is intensity drops whenever clouds block sunlight. Plant growth slows somewhat, but it does not stop. Plants culti-

vated under intermittent bright light coupled with less intense light stilt grow big and strong, but they take longer to mature. James used this simple principle as the foundation for more growroom experiments. The results were extraordinary.

Mr. Clean's attic growroom has two banks of lights overhead, each containing five 600-watt high-pressure sodium lamps. He's conducted many different experiments with light levels. The most productive method was to turn every other lamp on, creating a zigzag light pattern in the room. He switches half of the tights on for two hours. At the end of two hours, he turns off the first bank of five lights and turns on the second bank to reverse the zigzag Light pattern. He maintains this schedule for 12 hours, alternating every two hours. By having only five Lights on at any one time, he cuts his electricity consumption in half. In order for this system to work properly. a minimum of four lamps is necessary.

The first crop employing the new zigzag scheme with only five lamps on at any one time produced about 9.3 pounds (4.2 kilosl, roughly 70% the yield of the previous crop. James continued to refine the schedule with many more experiments. Yields continued to climb.

Our second stop is a growroom run by two beautiful young Dutch women, affectionatety known as "The Babes." Their first crop with James' custom-made Quick Switch Master controller looked good at first but caught a virus during flowering, and some plants died. The Babes were forced to harvest the remaining 110 healthy plants two weeks early, only seven weeks into flowering. When dry, the harvest weighed in at 4.8 pounds (2.2 kilos). Given the total amount of wattage (600-watt HPS), they harvested roughly 0.7 grams per watt for every 30 days of flowering. (The benchmark is 0.5 grams per watt for every 30 days.) This was a major improvement.

Their next crop yielded approximately 3.1 kilograms of top-quality bud from 150 plants - that's about 20.8 grams per plant, or 0.7 grams per watt per 30 days of flowering (1.4 grams per actual watt used during the entire flowering period). Yield was low because the clones were not grown long enough. (A group of Polish growers has recorded the highest yield thus far using this system: 1.6 grams per watt during eight weeks of flowering.)

"Clones are 'pregrowing' in this room," says James as we enter the third growroom on our tour. He advises giving clones 120 hours of pregrow time - either five days of round-the-clock light or seven days of 18-hour light. "If they're small or weak, let them pregrow until they're strong," James explains. A plant that hasn't been pregrown and set into flowering while still small will produce 35-50% fewer buds than a pregrown plant. Plants should be at least 10 inches (about 20 to 25 centimeters) high, with lots of side branches, before they get turned over to 12-hour light.

Light is only half the equation. For a heavy harvest, everything in the growroom must be integrated into a precise system. Lamps should be fixed 55 inches (1.4 meters) overhead and exactly 39 inches (1 meter) apart and set up in a matrix, so that illumination is even below. The plants will instinctively grow toward the static lamps.

Fresh, well-circulated, temperate air is the next most important element. James says that half of the evacuated air should be replenished immediately, creating a constant vacuum in the growroom. With proper air pressure, the door should have a tiny bit of negative pressure when opened. The next trick is to replenish the air so that it's evenly dispersed throughout the garden. Extracting air also creates a vacuum in the room that can be used to draw air in from a passive source. Direct the air along the length of the growing bed with flexible ducting. Cut 1-inch holes every 4 inches along the length of the duct. Cover some holes with duct tape and experiment with airflow volume. Use the tape to partially cover holes to balance incoming airflow along the length of the duct.

Air temperature should stay at or close to 75* to 80*F when the lights are on. Add a fan to bring more fresh air into the room. The intake fan can also be attached to a thermostat to further help regulate airflow.

The Quick Switch Master (QSM) turns the lights on and off in relation to the temperature. When the exhaust system can't keep the temperature below a given value, the QSM turns off progressively more lights until the temperature

drops to the appropriate level. Once the room is cool, the lights go progressively back on. If you get a couple of really warm days in a cold winter, the system automatically compensates. With the QSM, James' electricity costs decreased 25-30%.

He leaves the extraction fan on 24 hours a day. Circulation fans go on and off with the lights. This wet/dry irrigation schedule also helps regulate humidity, which runs between 55% and 65% when lights are on, and 40% to 45% when they're off. From the fifth to seventh weeks, humidity can drop another 10%. About a week before harvest, when the buds are large and compact, humidity sometimes jumps to 70-80%, due to the buds sweating at the tops.

The fourth room on the tour is a sea of big, fat buds. Olaf uses B'Cuzz with Atami A & B fertilizer and soil booster, starting with flowering complex from the second week until one week before harvest. He prefers an inexpensive potting soil with high peat content and 20% perlite. The advantage of using this soil and watering from below is that the plants don't need all the food at first; it's stored in the potting soil. When the plants' nutrient needs increase, they have reserves in the soil.

Adjust the pH to between 5.6 and 5.9. Adding Cannazym (an enzyme-rich soil improver from Canna) weekly from the onset through harvest helps to break down any residual fertilizer salts and old root systems from previous harvests.

Getting the feel for irrigation takes some practice. because the frequency varies. "In the beginning, I water the 3-gallon [11 -liter] pots about once a week," observes Olaf. "The closer it is to harvest time, the more often I water - usually three times a week." Irrigation solution fills the growing bed with about an inch of nutrient solution; it should take two to three days to be used. In two to five days, the solution will disappear. When the tray under the pot is dry for one full day, it's time to irrigate again.

The Quick Switch Master is quite economical. A double-switch box for 10 lamps costs less than $500 (E400); a smaller version, for six lamps, costs $250 (E200). No matter how you figure the investment out, it's less expensive to buy a switch box than the extra ballasts to run the lamps. The actual net decrease in electrical consumption works out to be 35%, because the crop takes 10 to 14 days longer to mature properly before harvest.

Increasing yield and lowering expenses is both a science and an art. When all factors - light, heat, air, water, nutrients, soil - are functioning at their highest capacities, you should have a heavy harvest.

James' technique integrates low- and high-tech solutions to maximize every facet of the growing equation. Apply some of these principles to your own grow, and watch expenses fall and yields soar.

Take care.

YUP.

do u understand how it DOES save power now?!?! that was the first problem when i tryed to explain it... you straight up shot down the fact it saves power....

if i can drop power and keep the same yield, then ive done my job right!

do u understand how it DOES save power now?!?! that was the first problem when i tryed to explain it... you straight up shot down the fact it saves power....

if i can drop power and keep the same yield, then ive done my job right!

E

emerald city

Excellant explaination of what Fb was talking about....I did like the fact the article talked about the interelationship of ALL enviromental factors influancing the growth patterns....This will be FatBlunt420....

Good read

E

emerald city

my only problem is useing that therory your timing of rotation is set back by 10-13 days..For me to keep the shedual of 13 cycles a year i need to stay strong with my timing...YUP.

do u understand how it DOES save power now?!?! that was the first problem when i tryed to explain it... you straight up shot down the fact it saves power....

if i can drop power and keep the same yield, then ive done my job right!

Love to hear your numbers on what your saving on your power bill and how things are working out for this therory..good luck bro.

power bills alittle personal. but i can give a rough estimate of what im saving.

so yields are set back 10 days in a full on stagger set up.

my idea incorporates 2 lighting methods. the sides should get the most growth w the bare bulbs. and the tops will still amount to somthing.

so yields are set back 10 days in a full on stagger set up.

my idea incorporates 2 lighting methods. the sides should get the most growth w the bare bulbs. and the tops will still amount to somthing.

...obviously IF i did a full stagger set up, we would be talking about twice as many hoods. spaced close together and all the intensity would be there...

YUP.

do u understand how it DOES save power now?!?! that was the first problem when i tryed to explain it... you straight up shot down the fact it saves power....

if i can drop power and keep the same yield, then ive done my job right!

I understood what you were trying to say right away... I Just don't think it will actually save power or increase yields...lol

I understood what you were trying to say right away... I Just don't think it will actually save power or increase yields...lol

well,,, i know it will save power.... plain and simply, less amps used = less power usage.... flipboxes draw a good amount less then having another 1k involved.

and i never claimed to get increase yields.

the goal is coverage, same yields and power saving.... its all there in this plain.

E

emerald city

Not to  but I had one more thought then ill let it go....Where is the point of diminishing returns on both ends...How much or how little light does it take to grow an "good: plant...?My garden experience says at least 6-8 direct sunlite is needed to grow most veggies so maybe 6 hour direct and 6 hours indirect might just work.....

but I had one more thought then ill let it go....Where is the point of diminishing returns on both ends...How much or how little light does it take to grow an "good: plant...?My garden experience says at least 6-8 direct sunlite is needed to grow most veggies so maybe 6 hour direct and 6 hours indirect might just work.....

Ive been a power hog so long i might have failed to see the lite...FB420 you may just be on to something.With power bill being our biggest cost even a % decrease would ammount to $ in the long run.

but I had one more thought then ill let it go....Where is the point of diminishing returns on both ends...How much or how little light does it take to grow an "good: plant...?My garden experience says at least 6-8 direct sunlite is needed to grow most veggies so maybe 6 hour direct and 6 hours indirect might just work.....

but I had one more thought then ill let it go....Where is the point of diminishing returns on both ends...How much or how little light does it take to grow an "good: plant...?My garden experience says at least 6-8 direct sunlite is needed to grow most veggies so maybe 6 hour direct and 6 hours indirect might just work.....Ive been a power hog so long i might have failed to see the lite...FB420 you may just be on to something.With power bill being our biggest cost even a % decrease would ammount to $ in the long run.

G

Guest3498

4-5 pages of talk and no budshots, c'mon people!!

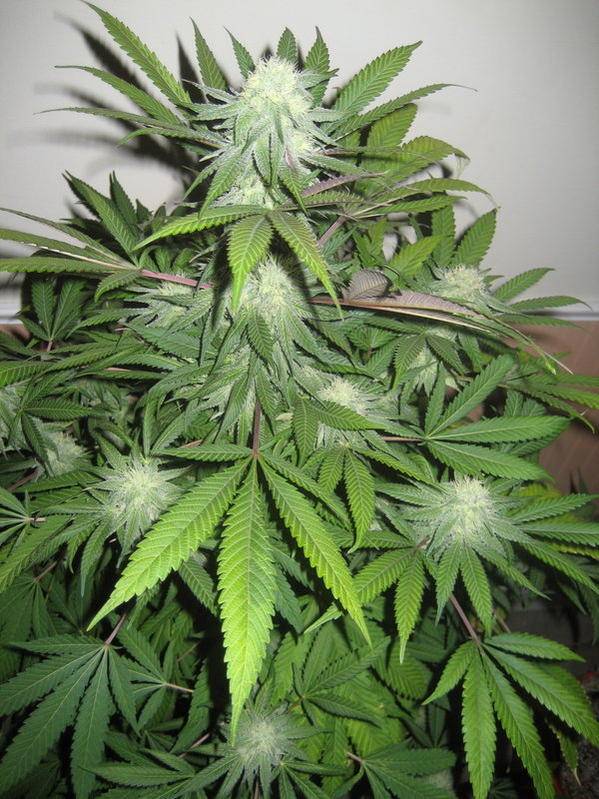

grandaddy purp

golden goat starting to get fat...

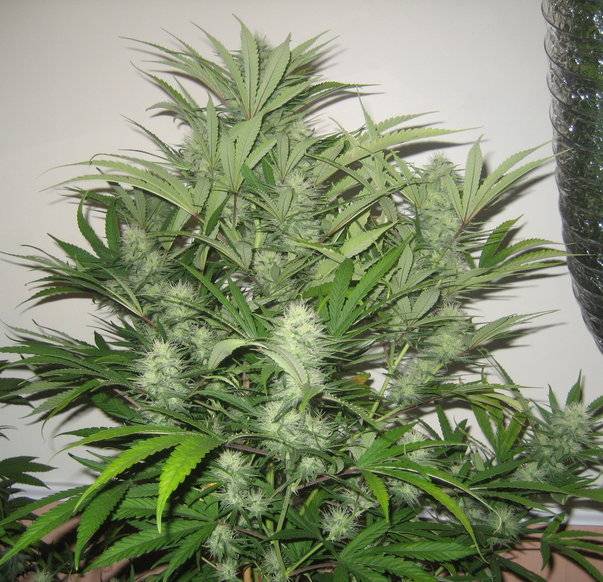

grandaddy purp

golden goat starting to get fat...