mr cheese

Member

manitu said:The most important stuff from the flip-flop thread:

The omron contactor is delivered in models from 24 to550V AC + many DC voltages.

ANY model can switch any voltage up to 600V at max the rated current, but they are made to start and stop big electric engines, and will handle spikes with higher voltage. (exept the "AR" model-only for single 400/600W)

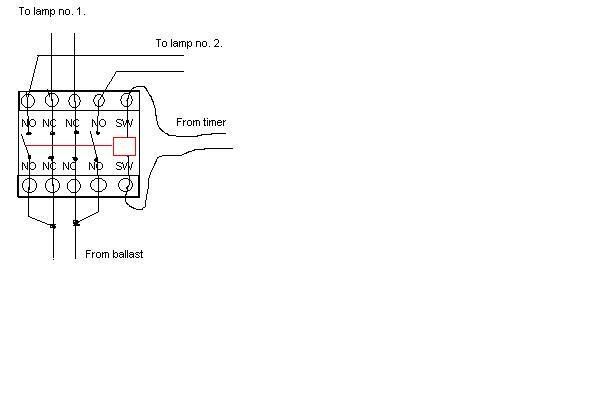

You can hook up four extra switches on top of the contactor, controlling an additional ballast! On some omron model, you can use eight! extra switches, controlling a total of three ballasts.( or six, if you go the single-pole route)

N.O. means "Normally Open"(not connected), N.C. means "Normally Closed"(connected)!

So lamp no. 1 must use the two N.C. channels, and lamp no. 2 must use the N.O. channels.

When you apply voltage from the timer, the N.C channels open, and the N.O. channels close.

Maybe this makes more sense.(sorry for the shitty paint-drawings..)

internals:

.manitu

same as livewire said, nice one for all the help manitu.

quick q for ya, you see the wires coming from the ballast? youv draw 4 wires, but the ballast (bulb)wires from the ballast only have 2, is this just a miss print? just im goingt with this idea and dnt wana blow myself up,lol....nice1....mrc