1 question on your original problem. Were the coils active ( pulled in to the normally open position )? If they were not you can most likely rule out the relays.

What Tilt is talking about here is that when relays are being used for a flip-flop (alternately driving two lamps with one ballast), one lamp would be driven when the relay coil is energized (the normally open contacts), and the other lamp would be driven when the coil is de-energized (the normally closed contacts). If the lights went out when the coil was not energized, the relays would not be the problem because they would not have momentarily dropped power to the lamp (necessitating a cool-down, restrike cycle).

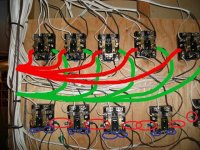

What Panama is talking about with the coil wiring is that you have two wires crimped together in each terminal on the coils. Each wire should have it's own terminal and then the two terminals screwed down together. Alternately, Tilt suggests pig-tailing the wires, which would mean there would be a single short length of wire coming from each coil connection which would then be wire-nutted to a main wire running from relay to relay.

The gutter suggestion is just that - a section of gutter running over the top of the electrical components to redirect any dripping water away from them.

The lexan idea that Tilt suggests is a clear, non-conductive plastic sheet mounted over the top of the components on stand-offs (spacers). This protects you from accidental contact with live equipment, but enables you to see what is going on.

Finally, unscrewing the lamps and leaving the ballasts hot is a very poor idea. By the way, you aren't getting fingerprints on the lamps when you screw them back in, are you? The oil from your fingerprints will break down the glass envelope of the lamp at the temperatures that they operate.