Blowstrees

Member

Lmao, Growers are worse than doctors sometimes with their pride and arrogance.

The point of this thread was to help people who are going to wire a new circuit to have a visual guide as to what they are doing. I myself am a visual learner, so the idea was to share what helped me understand. Im glad some got something useful out of the post.

Hazey, Should I be giving out electrical advice? Maybe not.

MadPenguin- Thank you for all your valid contributions to the thread. Im stoked that now for the 4th time, it can be clarified to use what's called a cable clamp when running new wire to your panel. I have explained above as to why I did not install one on this run. The purpose of the cable clamp, is to hold the cable in place so it does not rub against the sharp corners of the panel or your junction box.

http://www.hammerzone.com/archives/elect/panel/clamp_install.htm

The cables are not going anywhere...and even if they did...the 6-8 inches of insulation on the line INSIDE THE BOX will protect them. Although I will keep in mind your reference of just 2 cables per knock out.

As far as wire strippers go, they were already on my list of tools needed. Again the second time thats being mentioned and clarified. The only part of the cable that is being sliced by the razor blade is the split down the middle of the cable to expose the wires. The rest is being done with strippers to not damage the wire. You'd have to be some sort of an asshole to do that with a razor blade with wire strippers around. Spliting the wire in that nature came from my Home Depot book on Electricity.

As far as the order of your connections...the power to your whole house is off there guy. As far as I can see, I'd be safe as long as everything was connected properly. I did the hot first so im not limited in movement once my ground is connected.

Dudes like you annoy the hell out of me truthfully. The kind of guy who gets a rush out of

"playing spot the violations" and head hunting for little tidbits to chim in whether they have already been mentioned or not. Support issues with my staples? Lmao give me a break theyah guy! I never commented on anybody being a dick ( although Vinnythebat saw valid reason too) and you werent even the dude he was talking to!

Ill make sure to let anybody who comes in asking for electrical advice to check your thread out since you have already taken care of all the eletrical knowledge for us here at IC.

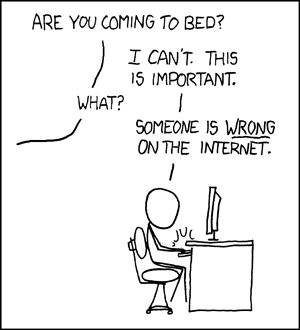

I bet this is you, huh??

Haha. But seriously , This is meant to help...if your just here to nit pick on whether or not I'm wearing gardening gloves for safety while Im doing it...or if you think my cable staples will have support issues...then please move on. If you actually find something that would put somebody in danger, by all means comment.

Thanks everybody else who enjoyed it.

The point of this thread was to help people who are going to wire a new circuit to have a visual guide as to what they are doing. I myself am a visual learner, so the idea was to share what helped me understand. Im glad some got something useful out of the post.

Hazey, Should I be giving out electrical advice? Maybe not.

MadPenguin- Thank you for all your valid contributions to the thread. Im stoked that now for the 4th time, it can be clarified to use what's called a cable clamp when running new wire to your panel. I have explained above as to why I did not install one on this run. The purpose of the cable clamp, is to hold the cable in place so it does not rub against the sharp corners of the panel or your junction box.

http://www.hammerzone.com/archives/elect/panel/clamp_install.htm

The cables are not going anywhere...and even if they did...the 6-8 inches of insulation on the line INSIDE THE BOX will protect them. Although I will keep in mind your reference of just 2 cables per knock out.

As far as wire strippers go, they were already on my list of tools needed. Again the second time thats being mentioned and clarified. The only part of the cable that is being sliced by the razor blade is the split down the middle of the cable to expose the wires. The rest is being done with strippers to not damage the wire. You'd have to be some sort of an asshole to do that with a razor blade with wire strippers around. Spliting the wire in that nature came from my Home Depot book on Electricity.

As far as the order of your connections...the power to your whole house is off there guy. As far as I can see, I'd be safe as long as everything was connected properly. I did the hot first so im not limited in movement once my ground is connected.

Dudes like you annoy the hell out of me truthfully. The kind of guy who gets a rush out of

"playing spot the violations" and head hunting for little tidbits to chim in whether they have already been mentioned or not. Support issues with my staples? Lmao give me a break theyah guy! I never commented on anybody being a dick ( although Vinnythebat saw valid reason too) and you werent even the dude he was talking to!

Ill make sure to let anybody who comes in asking for electrical advice to check your thread out since you have already taken care of all the eletrical knowledge for us here at IC.

I bet this is you, huh??

Haha. But seriously , This is meant to help...if your just here to nit pick on whether or not I'm wearing gardening gloves for safety while Im doing it...or if you think my cable staples will have support issues...then please move on. If you actually find something that would put somebody in danger, by all means comment.

Thanks everybody else who enjoyed it.