TrainingHay

Member

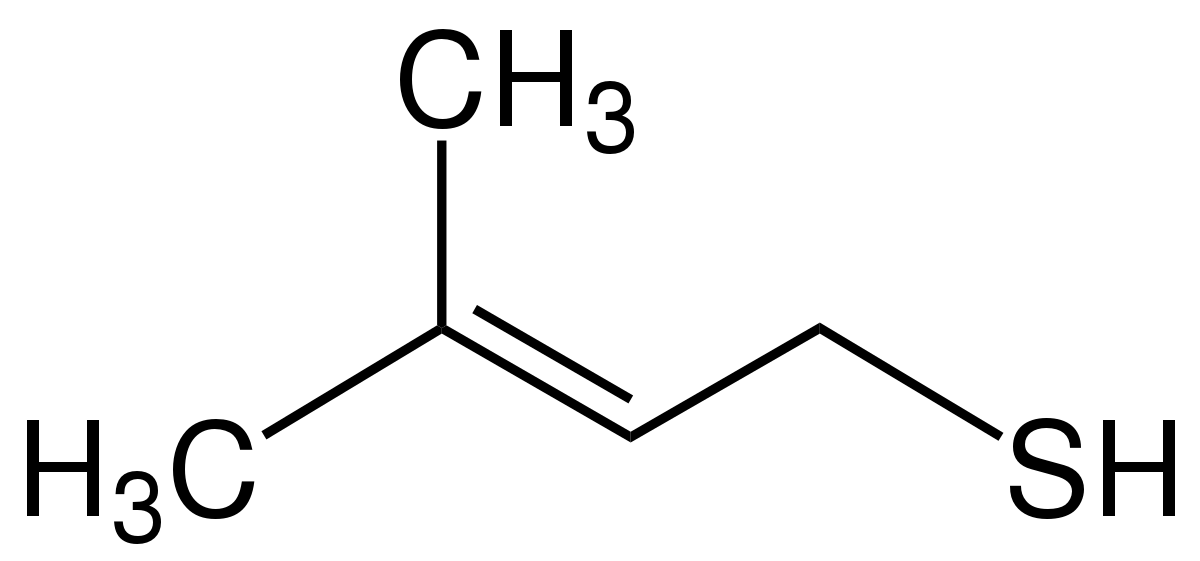

Thiol Means

The Cannabis industry has become aware that many desirable compounds in Cannabis are thiols[1,2]. So the question is, how to increase thiol content in the end product. So let the brainstorming begin.

Lipidation: The production of thiols in Cannabis relies on a hydrocarbon-derived carboxylic acid, such as butanoic acid from butane, attaching to a sulfur residue from cysteine.

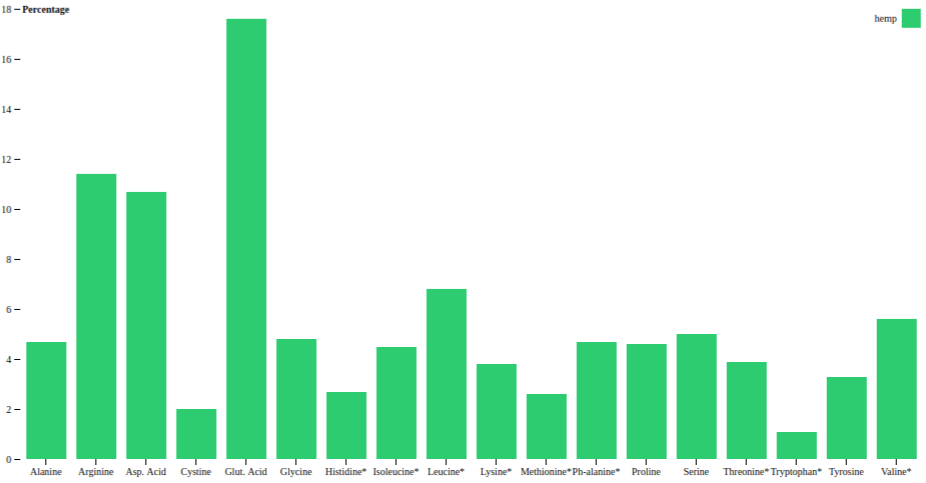

Skunk flavor for example is isovaleric acid, derived from leucine, attached to an SH group, derived from cysteine.

While a methionine deficiency is similarly disastrous, (induced hermaphrodism as ethylene is synthesized from methionine), a deficiency in cysteine leads to a deficiency in dankness. Neither methionine nor cysteine require much S. However, reduced N utilization in flower has been an extremely detrimental trend in Cannabis breeding/production. Example: If you see a Mb deficiency in bloom, you know the crop has not converted its nitrates to aminos and you shouldn't bid on that crop, as it is too far behind on nitrate metabolism to be of high quality.

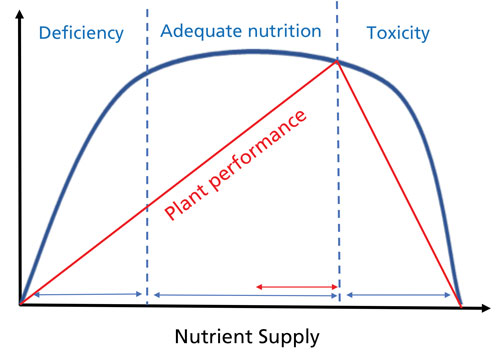

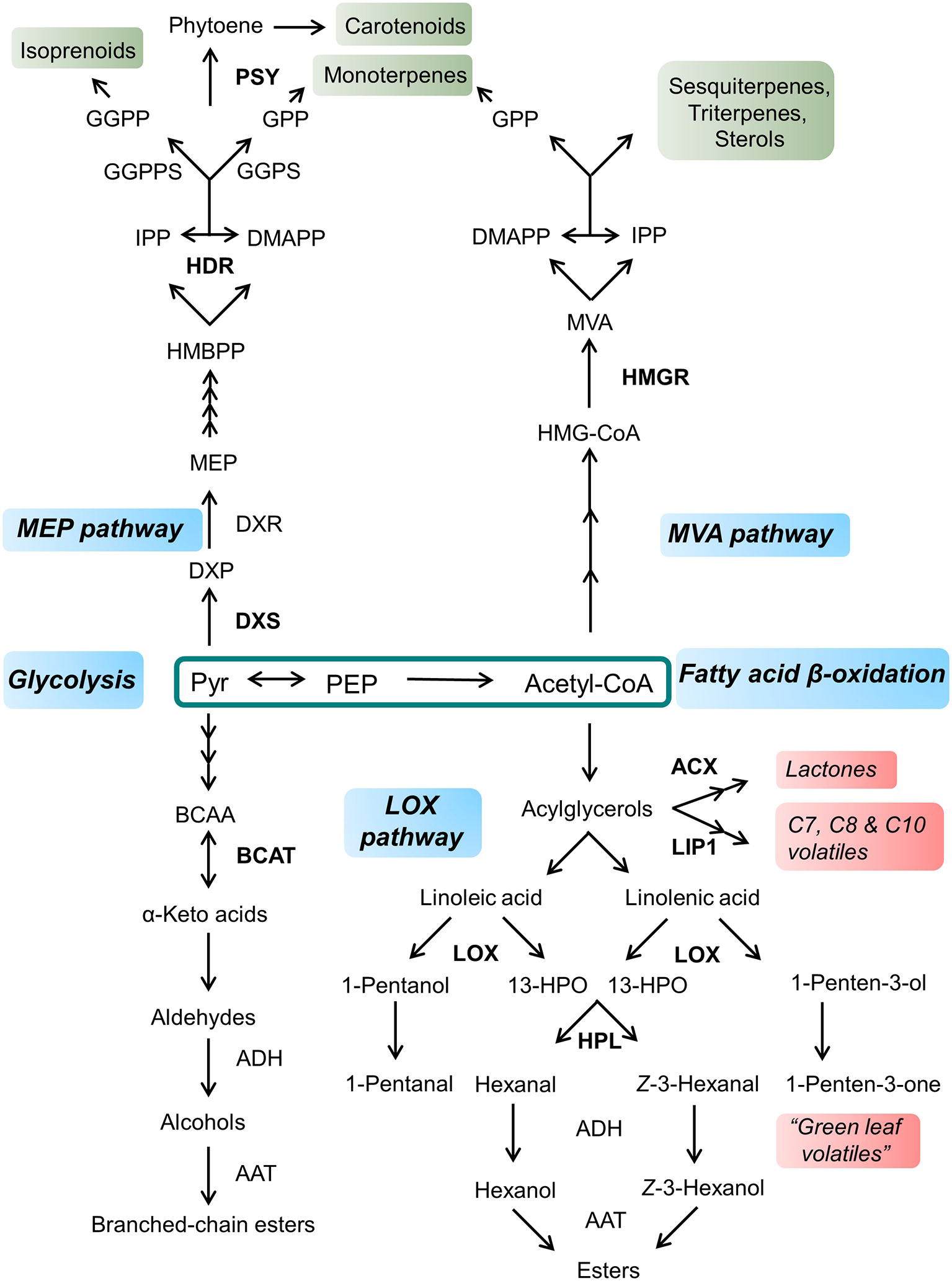

Phosphorus: The various pathways between initial photosynthesis and thiol production require phosphorus throughout. Phospholipids, pyrophosphate, adenosine triphosphate, isopenntyl diphosphate, phosphoenol pyruvate, dimethylallyl diphosphate, prenyl diphosphate, erythrose 4-phosphate, inositol hexaphosphate, riboflavin-5-phosphate, phosphatidic acids, 3-methyl-3-butenyl pyrophosphate, 3-methyl-2-butenyl pyrophosphate; it's obvious low phosphorus soils will not have the capability to keep up with the high P metabolism of high metabolite Cannabis. Cannabis willingly assimilates large amounts of P into its leaves and roots during vegative growth, in fact Cannabis will uptake a genetically determined maximum of P and convert it into proper forms for later use.The plant should store this energy early on to reach high thiol expression.

Plant health could be considered subjective. Some growers prefer to barely keep the crop alive, and add their own plant defenses in the form of sprays. If your college indoctrinated consultant's background is in ornamental hydroponics he may not best understand the end goals of Cannabis metabolism and how their chemical industry methodology is working against those goals.

Growing Cannabis is essentially a multi month chemical process. How can we save Cannabis energy in its process, game the system so to speak?

Precursors:

If Hexanoic acid is the most limiting step in the cannabinoid and terpenoid production of healthy crops[3], what is the weakest link in 3-methylated thiol production?

If 3 methyl butanoate is the precursor for 3-methyl-2-butene-1-thiol, would treating with isovaleric acid or leucine enhance 321MBT expression? Endogenous butyrate levels are low in most Cannabis[4].

Could that be why the skunk scent waivers in gardens that have proper nutrition? Likewise if 2 methyl 2 butene is the precursor, will beta-isoamylene supplementary be beneficial? Photooxidation famously causes lightstruck flavor in beer by oxidation of natural acid products. The flavin-like catalyst in this reaction is consumed in this scenario. How can we continue this oxidative reaction post harvest in Cannabis?

Post harvest:

Cannabis memorizes the length of its dark period, consumes its carbohydrate reserve during that period, and begins breaking down its proteins and lipids the minute its dark period is extended. How does this affect the ripening process of Cannabis when the goal is amino and lipid-derived thiols?

Gassing fruit with n-butanol increases its associated end products (ethyl 2-methylbutanoate) [5]. Would this suggest that fumigating Skunk Cannabis with ethyl isovalerate would enhance the end product?

Many microbes are capable of producing 3 methyl butanoate, ethyl isovalerate and related butane associated compounds which benefit the plant [6]. Is the added metabolic production of microbial activity a reason organic Cannabis is said to be superior to hydroponic Cannabis even when organic acid chelates are implemented in sterile hydroponic scenarios? The North American Project to Evaluate Soil Health Measurements would suggest so.

Curing?

Curing makes meh Cannabis meh, good Cannabis great, and great Cannabis excellent. And it makes bad cannabis worse. If you believe curing is nothing more than ritual aging, marketing lingo, molding, rotting, or other some type of unexplained spoilage: you probably shouldn't be anywhere in Cannabis production. Find a new job!

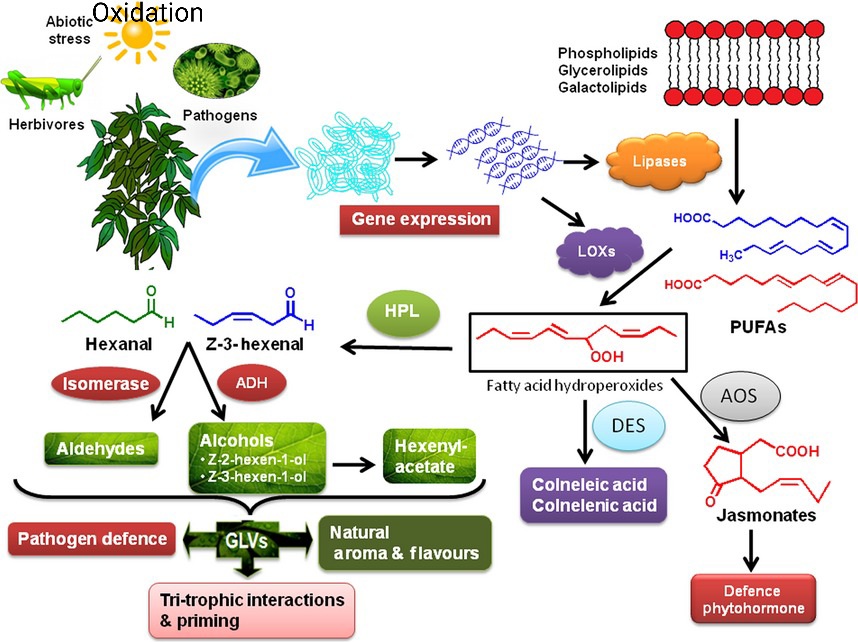

Curing is the break down of carbohydrates, lipids, amino acids and fatty acids, which requires oxidation. Quality Cannabis is always improved by curing. Freezing fresh Cannabis makes zero sense. Cannabis has a quantifiable post harvest climacteric peak of respiration, absolutely required for development of the end product.

Many flavor precursors continue to flow from the leaves roots and stems after harvest. Wet bucking haults this metabolism, usually producing hexanols, the hay smell, from hexanoic acid. Other factors affecting metabolomism are limited enzyme activity. Enzymes are nitrogenous compounds, coenzymes are trace minerals or electrolytes. Which of these nutrients can be applied post harvest to insure high enzyme activity?

PH?

Roses are said to express traditional smells better in a low pH soil while modern fruity aromas are better expressed in alkaline soil. Which soil pH best expresses traditional Cannabis thiols? Cannabis sap pH is largely determined by the uptake ratio of anions to cations. Are off the shelf fertilizer profiles even capable of producing high thiol content?

Thiols from Glycosides

Does Cannabis contain inactive thiols bound to carbon molecules, like glucosonulates in broccoli? The alcohol industries implement brewing yeasts that have high glucosidase/lyase activity to release various thiols from sugar molecules, making both flavor perceivable upon their decomposition.

While Cannabis is climacteric, it is not a fruit. Fruit loses organic acids to respiration and conversion to sugars. Cannabis resin can increase highly in acidity over time, causing many post harvest reactions yet to be characterized.

BREEDING

You can't breed Skunk if you don't grow skunky weed. Working with most Cannabis breeders is like doing chicken dentistry. A whole lot of unproductive noise. I believe most desirable Cannabis flavors to be hexanoates and butanoates. Many are acetates, and this is the reason behind OG Kush popularity. Cannabis is highly polymorphic. Example: Using a pickle scented OG Kush male will acetylate the terpenes of the mother. Females of Chem types offer up their SH group in bloom. Is there a characteristic trait to look for in a male which passes on the methyl group to its offspring? Downstream metabolites of the butyrate pathway include rubber precursors, fuel and butter/cheese scents, is there any validity to sifting rubber gas and dairy genetics for Skunk?

A variety high in both leucine and cysteine might be good breeding stock for classic Cannabis flavors.

Complex = Watered Down?

Complexity and variety is a narrative being sold. I don't believe breeders are doing much but watering down a polymorphic gene pool. Distinct recognizable flavors is what people want, and they want to be able to buy it twice, at any time. I don't think the craft flavors of the future will be very complex or seasonal at all. Nuance breeds pretention. I want to enjoy the experience not pretend to enjoy it. If have a Skunk line I want it louder and more distinct, not more complex. You can pretend to taste the terpinolene all you want, I still haven't found anyone who cares about those destructive "nuanced" flavors.

Metabolic pathways of Cannabis

Odor detection thresholds of some Cannabis metabolites:

1-methyl-4-(1-methylethenyl)-cyclohexene (limonene):

38 parts per billion

2-Methyl-6-methylen-1,7-octadien-3-on(Myrcene):

13 parts per billion

(S)-Ethyl 2-methylbutanoate :

0.006 parts per billion

3-methyl-2-butene-1-thiol:

0.000209 parts per billion

This means that 321MBT is 180,000 times stronger smelling than Limonene! What a waste of energy some terpenes can be!

The Secret of Scent with Luca Turin. Full series available: https://vimeo.com/ondemand/297742

References:

[1] https://pubs.acs.org/doi/10.1021/acsomega.1c04196

[2] https://pubs.acs.org/doi/10.1021/acsomega.3c04496

[3]

[4] https://www.researchgate.net/figure/Fatty-acid-composition-of-hemp-seed-oil_tbl1_358842625

[5] https://pubs.acs.org/doi/10.1021/bk-1992-0490.ch006

[6] https://www.researchgate.net/publication/352021369_C4_Bacterial_Volatiles_Improve_Plant_Health

The Cannabis industry has become aware that many desirable compounds in Cannabis are thiols[1,2]. So the question is, how to increase thiol content in the end product. So let the brainstorming begin.

Lipidation: The production of thiols in Cannabis relies on a hydrocarbon-derived carboxylic acid, such as butanoic acid from butane, attaching to a sulfur residue from cysteine.

Skunk flavor for example is isovaleric acid, derived from leucine, attached to an SH group, derived from cysteine.

While a methionine deficiency is similarly disastrous, (induced hermaphrodism as ethylene is synthesized from methionine), a deficiency in cysteine leads to a deficiency in dankness. Neither methionine nor cysteine require much S. However, reduced N utilization in flower has been an extremely detrimental trend in Cannabis breeding/production. Example: If you see a Mb deficiency in bloom, you know the crop has not converted its nitrates to aminos and you shouldn't bid on that crop, as it is too far behind on nitrate metabolism to be of high quality.

Phosphorus: The various pathways between initial photosynthesis and thiol production require phosphorus throughout. Phospholipids, pyrophosphate, adenosine triphosphate, isopenntyl diphosphate, phosphoenol pyruvate, dimethylallyl diphosphate, prenyl diphosphate, erythrose 4-phosphate, inositol hexaphosphate, riboflavin-5-phosphate, phosphatidic acids, 3-methyl-3-butenyl pyrophosphate, 3-methyl-2-butenyl pyrophosphate; it's obvious low phosphorus soils will not have the capability to keep up with the high P metabolism of high metabolite Cannabis. Cannabis willingly assimilates large amounts of P into its leaves and roots during vegative growth, in fact Cannabis will uptake a genetically determined maximum of P and convert it into proper forms for later use.The plant should store this energy early on to reach high thiol expression.

Plant health could be considered subjective. Some growers prefer to barely keep the crop alive, and add their own plant defenses in the form of sprays. If your college indoctrinated consultant's background is in ornamental hydroponics he may not best understand the end goals of Cannabis metabolism and how their chemical industry methodology is working against those goals.

Growing Cannabis is essentially a multi month chemical process. How can we save Cannabis energy in its process, game the system so to speak?

Precursors:

If Hexanoic acid is the most limiting step in the cannabinoid and terpenoid production of healthy crops[3], what is the weakest link in 3-methylated thiol production?

If 3 methyl butanoate is the precursor for 3-methyl-2-butene-1-thiol, would treating with isovaleric acid or leucine enhance 321MBT expression? Endogenous butyrate levels are low in most Cannabis[4].

Could that be why the skunk scent waivers in gardens that have proper nutrition? Likewise if 2 methyl 2 butene is the precursor, will beta-isoamylene supplementary be beneficial? Photooxidation famously causes lightstruck flavor in beer by oxidation of natural acid products. The flavin-like catalyst in this reaction is consumed in this scenario. How can we continue this oxidative reaction post harvest in Cannabis?

Post harvest:

Cannabis memorizes the length of its dark period, consumes its carbohydrate reserve during that period, and begins breaking down its proteins and lipids the minute its dark period is extended. How does this affect the ripening process of Cannabis when the goal is amino and lipid-derived thiols?

Gassing fruit with n-butanol increases its associated end products (ethyl 2-methylbutanoate) [5]. Would this suggest that fumigating Skunk Cannabis with ethyl isovalerate would enhance the end product?

Many microbes are capable of producing 3 methyl butanoate, ethyl isovalerate and related butane associated compounds which benefit the plant [6]. Is the added metabolic production of microbial activity a reason organic Cannabis is said to be superior to hydroponic Cannabis even when organic acid chelates are implemented in sterile hydroponic scenarios? The North American Project to Evaluate Soil Health Measurements would suggest so.

Curing?

Curing makes meh Cannabis meh, good Cannabis great, and great Cannabis excellent. And it makes bad cannabis worse. If you believe curing is nothing more than ritual aging, marketing lingo, molding, rotting, or other some type of unexplained spoilage: you probably shouldn't be anywhere in Cannabis production. Find a new job!

Curing is the break down of carbohydrates, lipids, amino acids and fatty acids, which requires oxidation. Quality Cannabis is always improved by curing. Freezing fresh Cannabis makes zero sense. Cannabis has a quantifiable post harvest climacteric peak of respiration, absolutely required for development of the end product.

Many flavor precursors continue to flow from the leaves roots and stems after harvest. Wet bucking haults this metabolism, usually producing hexanols, the hay smell, from hexanoic acid. Other factors affecting metabolomism are limited enzyme activity. Enzymes are nitrogenous compounds, coenzymes are trace minerals or electrolytes. Which of these nutrients can be applied post harvest to insure high enzyme activity?

PH?

Roses are said to express traditional smells better in a low pH soil while modern fruity aromas are better expressed in alkaline soil. Which soil pH best expresses traditional Cannabis thiols? Cannabis sap pH is largely determined by the uptake ratio of anions to cations. Are off the shelf fertilizer profiles even capable of producing high thiol content?

Thiols from Glycosides

Does Cannabis contain inactive thiols bound to carbon molecules, like glucosonulates in broccoli? The alcohol industries implement brewing yeasts that have high glucosidase/lyase activity to release various thiols from sugar molecules, making both flavor perceivable upon their decomposition.

While Cannabis is climacteric, it is not a fruit. Fruit loses organic acids to respiration and conversion to sugars. Cannabis resin can increase highly in acidity over time, causing many post harvest reactions yet to be characterized.

BREEDING

You can't breed Skunk if you don't grow skunky weed. Working with most Cannabis breeders is like doing chicken dentistry. A whole lot of unproductive noise. I believe most desirable Cannabis flavors to be hexanoates and butanoates. Many are acetates, and this is the reason behind OG Kush popularity. Cannabis is highly polymorphic. Example: Using a pickle scented OG Kush male will acetylate the terpenes of the mother. Females of Chem types offer up their SH group in bloom. Is there a characteristic trait to look for in a male which passes on the methyl group to its offspring? Downstream metabolites of the butyrate pathway include rubber precursors, fuel and butter/cheese scents, is there any validity to sifting rubber gas and dairy genetics for Skunk?

A variety high in both leucine and cysteine might be good breeding stock for classic Cannabis flavors.

Complex = Watered Down?

Complexity and variety is a narrative being sold. I don't believe breeders are doing much but watering down a polymorphic gene pool. Distinct recognizable flavors is what people want, and they want to be able to buy it twice, at any time. I don't think the craft flavors of the future will be very complex or seasonal at all. Nuance breeds pretention. I want to enjoy the experience not pretend to enjoy it. If have a Skunk line I want it louder and more distinct, not more complex. You can pretend to taste the terpinolene all you want, I still haven't found anyone who cares about those destructive "nuanced" flavors.

Metabolic pathways of Cannabis

Odor detection thresholds of some Cannabis metabolites:

1-methyl-4-(1-methylethenyl)-cyclohexene (limonene):

38 parts per billion

2-Methyl-6-methylen-1,7-octadien-3-on(Myrcene):

13 parts per billion

(S)-Ethyl 2-methylbutanoate :

0.006 parts per billion

3-methyl-2-butene-1-thiol:

0.000209 parts per billion

This means that 321MBT is 180,000 times stronger smelling than Limonene! What a waste of energy some terpenes can be!

The Secret of Scent with Luca Turin. Full series available: https://vimeo.com/ondemand/297742

References:

[1] https://pubs.acs.org/doi/10.1021/acsomega.1c04196

[2] https://pubs.acs.org/doi/10.1021/acsomega.3c04496

[3]

[4] https://www.researchgate.net/figure/Fatty-acid-composition-of-hemp-seed-oil_tbl1_358842625

[5] https://pubs.acs.org/doi/10.1021/bk-1992-0490.ch006

[6] https://www.researchgate.net/publication/352021369_C4_Bacterial_Volatiles_Improve_Plant_Health