Spanishwilly

Member

HI,

I just stole this little quote from a great article I'm reading on sealed grows...

"Note that if your A/C fails, your room can be subject to very high and very dangerous temperatures. Clever growers wire a 240V heating thermostat in line to the power supply of their lighting controls. The thermostat thinks that the lights are a heater and will keep the circuit open (supplying power to the lamps and ballasts) until a pre-set temperature is exceeded (i.e 92.5°F), then the power supplying the lamps will be shut-off saving you and your crop from disaster in the event of a failure in the A/C system."

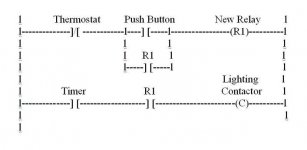

This is great, but here's my question. Do I wire it before my timer so that it would cut off power to the timer? Would that work?

Or should I wire it between the timer and the contactor?

Will it carry enough load to go straight to my lamps (4x600)?

Or what?

I'm in Europe.

I just stole this little quote from a great article I'm reading on sealed grows...

"Note that if your A/C fails, your room can be subject to very high and very dangerous temperatures. Clever growers wire a 240V heating thermostat in line to the power supply of their lighting controls. The thermostat thinks that the lights are a heater and will keep the circuit open (supplying power to the lamps and ballasts) until a pre-set temperature is exceeded (i.e 92.5°F), then the power supplying the lamps will be shut-off saving you and your crop from disaster in the event of a failure in the A/C system."

This is great, but here's my question. Do I wire it before my timer so that it would cut off power to the timer? Would that work?

Or should I wire it between the timer and the contactor?

Will it carry enough load to go straight to my lamps (4x600)?

Or what?

I'm in Europe.