Mulletsoda

Member

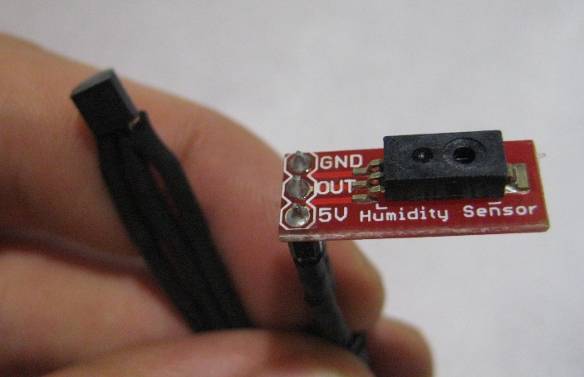

I'm designing a humidity / temp controller, and I thought I'd post up some pics and thoughts as the build unfolds. The situation here is the main adjustor is an exhaust fan which brings air in from a crawlspace type area. For the purposes of this design, I'm assuming the intake air is always going to be cool enough to bring the room temp down. However, the RH in there may be too high at times to bring the level in the room down, so there is a backup dehumidifier. It seems real simple, and it is, but outlining each step has proved to be a bigger task than I had thought.

At the moment I'm more concentrating on the logic behind it. Here are a few of my thoughts, things I feel need to be addressed in it's operation:

* When the vent is activated, I don't want it to turn back off right away. ( Example : if the sensor gets placed in the path of incoming air, as soon as it kicks it on, it will immediately register acceptable values again. ) A minimum on time will help prevent appliance cycling.

* I was thinking of an adjustable 'swing' amount for each value. ( Example : if your goal is 75 degrees, no swing would mean that 76.0 kicks it on and 75.9 (or 75.0) turns it back off. ) Depending on the size of the room being cooled, the room's ability to hold heat, the placement of the sensor and other factors, it may prove more efficient to activate your appliances less frequently.

* There will be a secondary RH sensor placed in the area where the intake draws it's air from to help the controller decide to use the vent or the dehumidifier.

* There will be the obvious things : an adjustable goal for temp, an adjustable goal for RH, a display (probably an 8x24 charactor LCD, just because I have it already), some sort of interface hardware (buttons and a knob), and a place to tie in electrical circuitry. This project is being done for an electrician (Yea!!) so I don't have to put outlets or any fancy packaging like that, he's going to wire his shit right to it.

Some other possible features I might put in :

* Timed outlet, depending on available memory and I/O pins

* Some sort of logging... maybe % of time ON over the last 12/24 hours

* Fault detection... if the vent is no longer having an effect, signal an alarm

* Saving settings to EEPROM (this will make your settings stay after the unit loses power)

At the moment I'm more concentrating on the logic behind it. Here are a few of my thoughts, things I feel need to be addressed in it's operation:

* When the vent is activated, I don't want it to turn back off right away. ( Example : if the sensor gets placed in the path of incoming air, as soon as it kicks it on, it will immediately register acceptable values again. ) A minimum on time will help prevent appliance cycling.

* I was thinking of an adjustable 'swing' amount for each value. ( Example : if your goal is 75 degrees, no swing would mean that 76.0 kicks it on and 75.9 (or 75.0) turns it back off. ) Depending on the size of the room being cooled, the room's ability to hold heat, the placement of the sensor and other factors, it may prove more efficient to activate your appliances less frequently.

* There will be a secondary RH sensor placed in the area where the intake draws it's air from to help the controller decide to use the vent or the dehumidifier.

* There will be the obvious things : an adjustable goal for temp, an adjustable goal for RH, a display (probably an 8x24 charactor LCD, just because I have it already), some sort of interface hardware (buttons and a knob), and a place to tie in electrical circuitry. This project is being done for an electrician (Yea!!) so I don't have to put outlets or any fancy packaging like that, he's going to wire his shit right to it.

Some other possible features I might put in :

* Timed outlet, depending on available memory and I/O pins

* Some sort of logging... maybe % of time ON over the last 12/24 hours

* Fault detection... if the vent is no longer having an effect, signal an alarm

* Saving settings to EEPROM (this will make your settings stay after the unit loses power)

. I could not even remember basic!!LOL Can't wait to hear how it works.

. I could not even remember basic!!LOL Can't wait to hear how it works.