No, the high pressure that I was talking about was in the refrigerant lines. If the pressure doesn't bleed off when the unit shuts off, the compressor has to start up against the back pressure and it can stall the compressor motor. I've never used a chiller, but assume that it works like any refrigeration unit.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Growroom Electricity and Wiring

- Thread starter Phillthy

- Start date

nightridda

Member

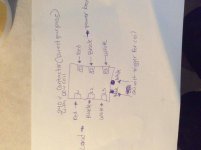

Rives I'm back with a quick question. I added another flower room on another panel as of right now I'm running 115 receptacles but want to use a 220 t104 timer. Is there a way to do this? Maybe run each hot to a different Receptacle? Then my next question would be I have atleast 3 receptacles with 3 (1000 ) watt lites. 1 on eeach.. how would I wire 3 receptacles to (1) 30 amp t104 ? Check out the picture .. any ideas ?

Attachments

I would feed the T104 with your 30a, 240v circuit and then use a small sub-panel downstream of the timer to break the circuit down and protect it properly. You can't feed 15 or 20a receptacles with 30a - the breaker needs to be sized at or below the lowest-rated component in the circuit. You can pick up a 4-circuit panel at Home Depot or Lowes for under $20, and the breakers are about $5 each. Try and keep the load balanced as best you can. 3 lights on 2 phases isn't going to balance, but if you put 2 lights on one phase with the other light and any auxiliary equipment on the other, it will be about as good as you can get it.

nightridda

Member

Can I do this

Main panel double pile 40 amp 240 --> Sub panel 30 amp 240 double pole --> Timer 30 amp 240 --> sub panel (then break it off to 20amp receptacles .. 4 of them as ur saying balance the load..

Main panel double pile 40 amp 240 --> Sub panel 30 amp 240 double pole --> Timer 30 amp 240 --> sub panel (then break it off to 20amp receptacles .. 4 of them as ur saying balance the load..

nightridda

Member

Alright sounds good I appreciate the help

nightridda

Member

nightridda

Member

The main power will come in on the L1, 2, etc., side and the switched power comes out of the T1, 2, etc., side. Be sure and use the same numbers for the in>out. For instance, if the power is connected to L1 and L2, then you have to use T1 and T2 for the output.

The control power connections should be down low on the sides or ends and need to match the voltage of the device that is controlling the relay. If you are using a standard digital timer, then the relay's coil needs to be 120vac. There are 24vac coils that would work with a sprinkler timer, and virtually any other voltage that you can think of for interfacing with devices around the world, so you will need to verify what you have to insure that it is compatible.

The other relays in your second post are similar. Switched power connections go directly across from one another on the contacts, and the control power will connect to the relay coil.

The control power connections should be down low on the sides or ends and need to match the voltage of the device that is controlling the relay. If you are using a standard digital timer, then the relay's coil needs to be 120vac. There are 24vac coils that would work with a sprinkler timer, and virtually any other voltage that you can think of for interfacing with devices around the world, so you will need to verify what you have to insure that it is compatible.

The other relays in your second post are similar. Switched power connections go directly across from one another on the contacts, and the control power will connect to the relay coil.

nightridda

Member

I don't know much about this I think I better just wait till pay day and buy the sub panel or I'm going to end up doing something I shouldn't

nightridda

Member

And there is no diagrams on Google images:/

nightridda

Member

I know my 120v timer would go into the side aka the 120 part you have labeled but how would this help me get a 120 ballast wired ?

nightridda

Member

I have 4k worth of lights that I need timed. How would the contactors help me. Put 20 amp in load side. And line out to where ? A recepticles box ? Would I need 4 contactors then?

First, 4k of lighting, with ballast losses, is going to draw roughly 37 amps if run on 120v. To do this on a single breaker you would need to upsize to a 50a breaker because of the 80% rule (any load over 3 hours in duration is limited to 80% of the breaker size). You would be far better off going with 240v ballasts and multiple circuits. EVERYTHING in the circuit needs to be be rated equal to or higher than the breaker protecting the circuit, so all of the receptacles, cordsets, etc, all need to be rated for the full current provided by the breaker.

The best way to handle these installations is to stick with either 15 or 20 amp circuits so that you can use standard receptacles, cordsets, etc. On 120v, a 1k ballast with losses is going to pull a little over 9 amps. So, with the 80% rule in mind, you will be limited to one ballast per 15 or 20 amp circuit (12 or 16 amps, respectively, is what you will be able to use). Going with 240v ballasts cuts the amperage in half, so you could run 2 on a 15a circuit or 3 on a 20a.

Contactors are used because digital timer contacts aren't heavy-duty enough to handle the load of ballasts, which are very difficult loads for contacts. The T104 that you mentioned up above is an exception - it is a water heater timer and is capable of handling very high loads. If you have the T104 feeding a sub-panel, then you can get the timing control that you need AND the circuit protection. Why are you pursuing the relays, have your needs changed?

There are endless ways of doing this, but it sounds as though you have very little electrical background and need to either stick with a simple plan or perhaps hire a qualified electrician if you want something more complex.

The best way to handle these installations is to stick with either 15 or 20 amp circuits so that you can use standard receptacles, cordsets, etc. On 120v, a 1k ballast with losses is going to pull a little over 9 amps. So, with the 80% rule in mind, you will be limited to one ballast per 15 or 20 amp circuit (12 or 16 amps, respectively, is what you will be able to use). Going with 240v ballasts cuts the amperage in half, so you could run 2 on a 15a circuit or 3 on a 20a.

Contactors are used because digital timer contacts aren't heavy-duty enough to handle the load of ballasts, which are very difficult loads for contacts. The T104 that you mentioned up above is an exception - it is a water heater timer and is capable of handling very high loads. If you have the T104 feeding a sub-panel, then you can get the timing control that you need AND the circuit protection. Why are you pursuing the relays, have your needs changed?

There are endless ways of doing this, but it sounds as though you have very little electrical background and need to either stick with a simple plan or perhaps hire a qualified electrician if you want something more complex.

Last edited:

nightridda

Member

I'm pretty much learning everything I know from you. As of right now I have a 6/3 to a subpanel. Then 4(20 amp) single pole breakers. ("Balanced") ran to there own recepticle. With 1 ballast on each. The delihma is the timer.. I don't have another sub panel and can't afford one till next Friday to use the t104 but I do have the relays. I just want it safe untill I get paid and can get the subpanel

nightridda

Member

I'm a fast learner though and I have learned a lot I just don't have a set way to go. What way do you suggest.. n how would I hook up the ballast to 240.

Double pole 20 amp to timer to recepticle.. n what about cords can I just hard wire them in?

Double pole 20 amp to timer to recepticle.. n what about cords can I just hard wire them in?

If the only thing on your existing sub is the lighting, then you could pull the 6/3 out that is feeding it and run it through your T104. If you are powering other circuits out of that sub, they will only be active while the lights are on.

It is legal to run 15a receptacles on a 20a breaker, but the circuit is required to feed more than one receptacle. In looking at your picture more closely, you need to get some romex clamps on the wires going in and out of that panel.

Swapping the ballast to 240v is dependent on how the ballast is made. Some are single-voltage only, some require changes in internal jumpering, and some will automatically adjust to whatever they are fed. The cords could be hardwired or you could use Nema 6-15 or 6-20 receptacles and plugs.

It is legal to run 15a receptacles on a 20a breaker, but the circuit is required to feed more than one receptacle. In looking at your picture more closely, you need to get some romex clamps on the wires going in and out of that panel.

Swapping the ballast to 240v is dependent on how the ballast is made. Some are single-voltage only, some require changes in internal jumpering, and some will automatically adjust to whatever they are fed. The cords could be hardwired or you could use Nema 6-15 or 6-20 receptacles and plugs.

nightridda

Member

I have a 12k and a 6k BTU air conditioner and 2 inlet ND 2 outlet fans. My carbon scrubber fan.. I have the greenhouse master controller.. my whole veg room 4 of the 4bulb t5 fixtures and the ez cloner. Yeah too much. I would have to get another sub panel. How far are you from ct Rives lol wanna make some money ?? Lmao

nightridda

Member

The problem with me getting an electrician is I don't trust anyone or I would have already. They are not stupid he's going to instantly know why I want it hooked up that way lol