-

ICMag with help from Phlizon, Landrace Warden and The Vault is running a NEW contest for Christmas! You can check it here. Prizes are: full spectrum led light, seeds & forum premium access. Come join in!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Grow room accidents (serious)

- Thread starter Iamnumber

- Start date

methias

Active member

Can I ask how your float valve failed? was it human error not fully engaging the thumb screw properly or the actual float failed?

Toilets have floats in them and rarely fail, so i'm interested to know how this happened.

Not looking to burst anyones bubble but IMHO toilet float valves fail all the time. Toilets however have an overflow drain that allows the water to harmlessly (except for the wasted H2O) drain to the sewer instead of on the floor.. I believe that everyone has (at one time or another) needed to "adjust the float" to stop the flow of water when the valve gets stuck open because of water scale build up.

To prevent flooding when using similar valves one should set up a similar overflow drain to a sewer line or (like in the A/C industry) setting up a condensation drain pump to deal with overflow. Those pumps can be wired to an alarm to let you know that the fill valve is stuck on so you can correct the problem.

Hope this helps.

Vape on kids

Fitzera

Well-known member

Not looking to burst anyones bubble but IMHO toilet float valves fail all the time. Toilets however have an overflow drain that allows the water to harmlessly (except for the wasted H2O) drain to the sewer instead of on the floor.. I believe that everyone has (at one time or another) needed to "adjust the float" to stop the flow of water when the valve gets stuck open because of water scale build up.

To prevent flooding when using similar valves one should set up a similar overflow drain to a sewer line or (like in the A/C industry) setting up a condensation drain pump to deal with overflow. Those pumps can be wired to an alarm to let you know that the fill valve is stuck on so you can correct the problem.

Hope this helps.

Vape on kids

Well I wouldnt so much say they fail in toilets all the time...they tend to stick sometimes. But I dont find that to happen nearly as often as you suggest. But I can hear when our toilets are running, as well as the water going down the drain in the basement.

Having a backup plan though is a very smart idea

nahual

Member

Just a little safety tip (pun intended) for anyone who might use sticks to support heavy buds.

Put a ping pong ball on the top of every stick in the pot.

You don't want to poke an eye out while inspecting or moving your ladies baked.

Vape on kids.

sage advice. im off to find some tennis or ping pong balls!

Serious Fire burned house - flames out of windows and structural damage (repairable but looks like 5 fig estimate quota)

News report stated that the fire started from indoor cannabis grow light.

No details given on HOW the fire started or what caused this.

Second grow area was found in storage building next to the house ( so I guess the grower had some experience ).

News report stated that the fire started from indoor cannabis grow light.

No details given on HOW the fire started or what caused this.

Second grow area was found in storage building next to the house ( so I guess the grower had some experience ).

A unit burnt down in Derby, lighting up the neighbour. It turned out he had a grow to. His unit in turn lit up the next one. Who it turned out.. had a grow. All 3 burnt down. Non of them knew the other units were growing.

I don't know, but imagine it was a wiring nest that somebody disturbed. It's very easy to pull an IEC out, if you don't plan your install properly.

All our lights come with cold condition IEC's. They cost pennies. The one's in your kitchen are hot condition. Our lights used to get them, and I never changed any until cost cutting made the switch to... printer cables.

I don't know, but imagine it was a wiring nest that somebody disturbed. It's very easy to pull an IEC out, if you don't plan your install properly.

All our lights come with cold condition IEC's. They cost pennies. The one's in your kitchen are hot condition. Our lights used to get them, and I never changed any until cost cutting made the switch to... printer cables.

plutiot

Active member

oh i got a good one. 2019/2020 full on drougth of smoke, my first grow, traded a hps/ballast/tent/extractor, for some hash, he has his own internet grow shop, (feels like it hasnt been updated since 2003 but whatever) so i had to cut and make the wires myself, witch is pretty stupid when u dont know nothing about electricity or growing, anyway tested the hps, 600 watts hell yeah, stands up in exitement and my apartment goes black, goes turn on the power again, one of the wires in the 600 bulb wasnt screwed propely in, then made contact/ground with the reflector piece, made a mark thats visible to this day i think (i can check tomorrow) and it happen while i was in contact with that reflector (just barely) in stupid exitement because the bulb worked, got a bit more respect now.. got only LED. from now on.. maby a cfl.. oh also cut the tip of my finger in my extractor fan this round because i wasnt happy with how the fans angle looked... halfway down my fingernail on my rigth hand, i bled for this grow

this is an excellent tip i use it in my garden all the timeJust a little safety tip (pun intended) for anyone who might use sticks to support heavy buds.

Put a ping pong ball on the top of every stick in the pot.

You don't want to poke an eye out while inspecting or moving your ladies baked.

Vape on kids.

Tynehead Tom

Well-known member

every grow room needs a high temp shut off to kill the power to the entire building.

EVERYONE should be using these devices

Fire in the grow room is no joke and will be toxic as hell. A high temp shut off won't put out a fire but it will stop further ignition from sparking electrical and in most cases will kill the power before an actual fire ignites.

The next step in the grow room fire proofing should be fire extinguishers for sure..... more than one.

The ultimate grow room fire protection would be a bank of C02 tanks rigged up just like a fire suppression sprinkler system and when the high temp shut off triggers, those tanks empty themselves via high volume emitters at the ceiling. C02 is a heavy gas and will fall just like water, purging the environment of oxygen needed for a fire. The bonus will be that your plants, if they survived, will be salvageable and not covered in fire extinguisher chemicals.

I've never had a safety issue in the grow rooms but I am always super careful.... that said we are humans and make mistakes LOL

The worst canna related accident I have seen the aftermath of was back in the 90's when some friends were making a batch of honey oil using a pressure cooker as the purging environment. These guys had done this for years the same way and they made excellent oil. This one time though, something plugged the pressure vent from the inside (we figure) and the pressure cooker exploded , completely demolishing the kitchen of the rental house and sent both my friends to the hospital. The damage to the house was incredible and I think about it every time i go to use my big pressure canner for a load of canned fish. One had 3rd degree burns from his belt line to his chin and was hospitalized for months in the burn unit. The other one didn't get burned but took a couple pieces of shrapnel that required serious stiching. Those two refused to make oil ever again after doing it safely for years.

EVERYONE should be using these devices

Fire in the grow room is no joke and will be toxic as hell. A high temp shut off won't put out a fire but it will stop further ignition from sparking electrical and in most cases will kill the power before an actual fire ignites.

The next step in the grow room fire proofing should be fire extinguishers for sure..... more than one.

The ultimate grow room fire protection would be a bank of C02 tanks rigged up just like a fire suppression sprinkler system and when the high temp shut off triggers, those tanks empty themselves via high volume emitters at the ceiling. C02 is a heavy gas and will fall just like water, purging the environment of oxygen needed for a fire. The bonus will be that your plants, if they survived, will be salvageable and not covered in fire extinguisher chemicals.

I've never had a safety issue in the grow rooms but I am always super careful.... that said we are humans and make mistakes LOL

The worst canna related accident I have seen the aftermath of was back in the 90's when some friends were making a batch of honey oil using a pressure cooker as the purging environment. These guys had done this for years the same way and they made excellent oil. This one time though, something plugged the pressure vent from the inside (we figure) and the pressure cooker exploded , completely demolishing the kitchen of the rental house and sent both my friends to the hospital. The damage to the house was incredible and I think about it every time i go to use my big pressure canner for a load of canned fish. One had 3rd degree burns from his belt line to his chin and was hospitalized for months in the burn unit. The other one didn't get burned but took a couple pieces of shrapnel that required serious stiching. Those two refused to make oil ever again after doing it safely for years.

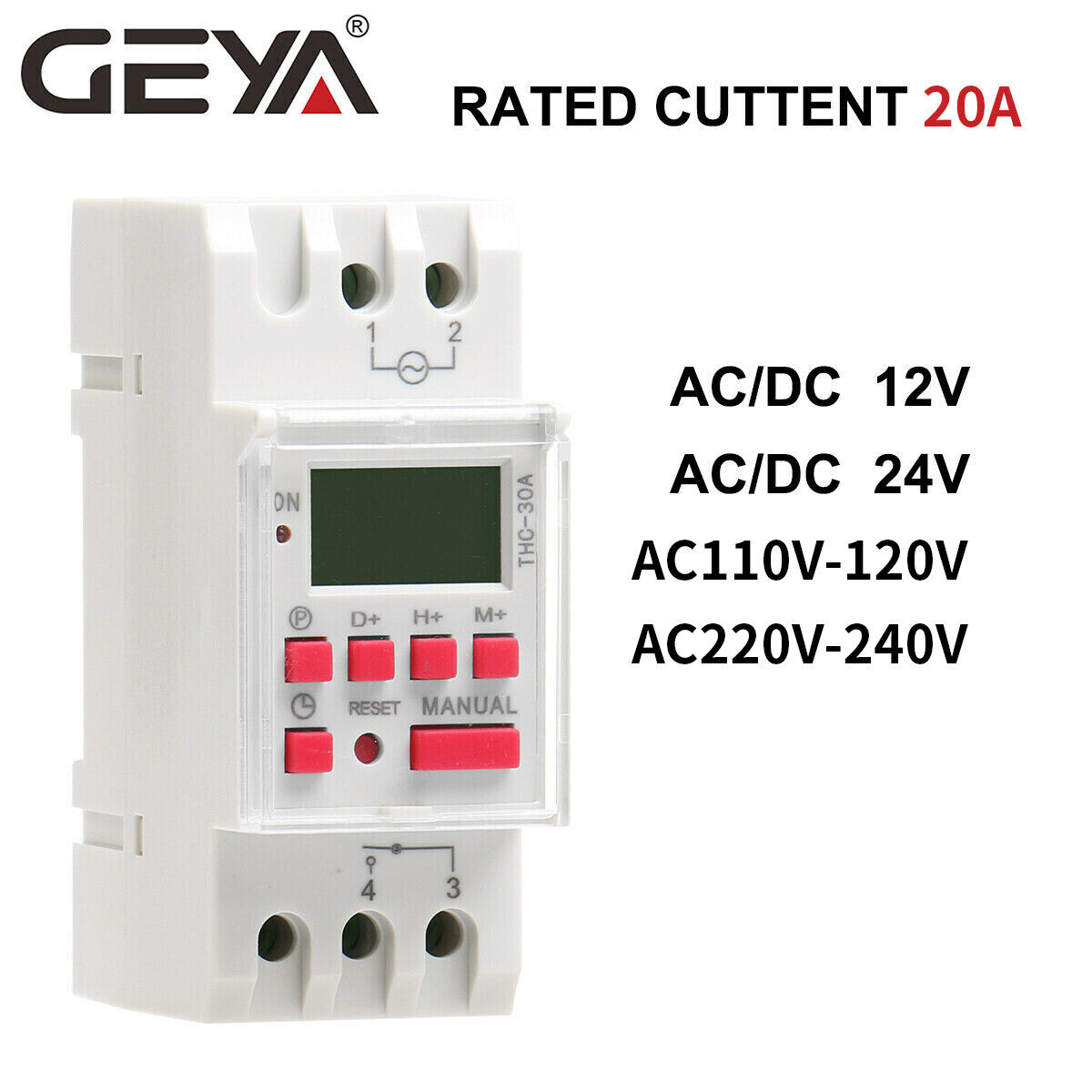

Would avoid useing cheap timers from china , have seen a number arc and stick in the on position , melting the plastic case.

An infra red heat sensor with a laser is dirt cheap and well worth pointing at plugs , leds and cables looking for hot spots , found a couple of loose wired plugs this way and a manufacturing break in a brand new extension cord that could have been a fire hazard.

An infra red heat sensor with a laser is dirt cheap and well worth pointing at plugs , leds and cables looking for hot spots , found a couple of loose wired plugs this way and a manufacturing break in a brand new extension cord that could have been a fire hazard.

After reading this collection of horror stories replete with warnings about cheap Chinese timers, I want to seek advice here about this type of digital timer that I've used for about a year now in my first ever indoor grow. I use a total of three of these timers to run my generic Chinese LED grow lights such that no light runs continuously for more than one hour as a safeguard to prevent overheating of any of those three lights.

Thus far the only departure from normal timer operations has been when the timers' AA batteries run low and need to be replaced. When that happens the timers behave erratically but with no overheating or electrical shorts developing. My question to those with far more indoor growing experience than I, is whether anyone has experienced any fire outbreaks or electrical shorts with these cheap Chinese digital timers. Thanks in advance for any insights that can be shared.

Thus far the only departure from normal timer operations has been when the timers' AA batteries run low and need to be replaced. When that happens the timers behave erratically but with no overheating or electrical shorts developing. My question to those with far more indoor growing experience than I, is whether anyone has experienced any fire outbreaks or electrical shorts with these cheap Chinese digital timers. Thanks in advance for any insights that can be shared.

Over 10 years ago, I had some very serious surgery that sidelined me from going out to my grow regularly. One of my employees offered to take care of it for me for four months and he did a very good job until he decided to let water run down on a plug strip, which was sitting on the floor. Water hit the plug strip and caught on fire and the room was torched. I lost over 100 plants and damn near. Lost my shop. A CO2 extinguisher and a hose took care of it before it got out of hand but I was about 10 seconds away from losing the entire building along with a few of my classic cars . I’m still using plug strips, but I have them wrapped up with freezer bags and taped around the end, so no water can intrude. The moral of the story is to watch where the water goes after it leaves the plant. If it overflows on anything electrical, you’re gonna go through what I did

SlangZaddy

New member

That's messed up for your friends, 3rd degree burns are farkin awful but still glad no-one lost an eye.every grow room needs a high temp shut off to kill the power to the entire building.

EVERYONE should be using these devices

Fire in the grow room is no joke and will be toxic as hell. A high temp shut off won't put out a fire but it will stop further ignition from sparking electrical and in most cases will kill the power before an actual fire ignites.

The next step in the grow room fire proofing should be fire extinguishers for sure..... more than one.

The ultimate grow room fire protection would be a bank of C02 tanks rigged up just like a fire suppression sprinkler system and when the high temp shut off triggers, those tanks empty themselves via high volume emitters at the ceiling. C02 is a heavy gas and will fall just like water, purging the environment of oxygen needed for a fire. The bonus will be that your plants, if they survived, will be salvageable and not covered in fire extinguisher chemicals.

I've never had a safety issue in the grow rooms but I am always super careful.... that said we are humans and make mistakes LOL

The worst canna related accident I have seen the aftermath of was back in the 90's when some friends were making a batch of honey oil using a pressure cooker as the purging environment. These guys had done this for years the same way and they made excellent oil. This one time though, something plugged the pressure vent from the inside (we figure) and the pressure cooker exploded , completely demolishing the kitchen of the rental house and sent both my friends to the hospital. The damage to the house was incredible and I think about it every time i go to use my big pressure canner for a load of canned fish. One had 3rd degree burns from his belt line to his chin and was hospitalized for months in the burn unit. The other one didn't get burned but took a couple pieces of shrapnel that required serious stiching. Those two refused to make oil ever again after doing it safely for years.

The CO2 thing is absolute genius.

Drop That Sound

Well-known member

I got one kind of like that. Never used it, but its made to fit in a receptacle with a switch plate cover.. Its an INTERMATIC brand at least, so pretty sure it wouldn't crap out. I tend to trust their timers the most.

Drop That Sound

Well-known member

I've seen so many reviews for cheap chinese junk that never ends up being close compared to what its advertised as far as the amount of amps it can handle. Relays and whatnot.

Drop That Sound

Well-known member

+

Tynehead Tom

Well-known member

this is why i like quality relays and self built controllers along with those gfci outlets on everything.

The control center for my grow is all controlled by relays which are controlled by sealed indoor/outdoor timers. The timers never get put under the load of ballasts they only trip relays. I get all my parts through an electrical wholesaler I know and I only source the very best components though I leave that to my electrician to decide what is "best" when I order. My control box was originally built in the early 2000's but it's all analog so it's completely rebuildable if you understand the basics of wiring receptacles. I can run up to 8 x 1000w lamp flower room with 2 remaining hot plugs for fan controllers but the timer only trips the relay for the 8 receptacles that power lights. This takes all that load away from the timer as it's only job it to send electricity to trip the relay. I haven't ran it with 8 lights in years but it has been an exceptionally reliable piece of equipment in safe power distribution in my grow rooms. If I ever scale back up to running 8000W of flowering lights per room I could run 2 full rooms on this box as the relay either turns one room on and off or it can turn on a second room while the other is dark..... a "flip" relay as we used to call it.

So an analog relay box, a quality indoor/outdoor digital timer and a high heat power shut off at the main..... can't think of a safer way to grow other than in my greenhouse under the sunshine hehe

And these analog control boxes are easy to build and very affordable

The control center for my grow is all controlled by relays which are controlled by sealed indoor/outdoor timers. The timers never get put under the load of ballasts they only trip relays. I get all my parts through an electrical wholesaler I know and I only source the very best components though I leave that to my electrician to decide what is "best" when I order. My control box was originally built in the early 2000's but it's all analog so it's completely rebuildable if you understand the basics of wiring receptacles. I can run up to 8 x 1000w lamp flower room with 2 remaining hot plugs for fan controllers but the timer only trips the relay for the 8 receptacles that power lights. This takes all that load away from the timer as it's only job it to send electricity to trip the relay. I haven't ran it with 8 lights in years but it has been an exceptionally reliable piece of equipment in safe power distribution in my grow rooms. If I ever scale back up to running 8000W of flowering lights per room I could run 2 full rooms on this box as the relay either turns one room on and off or it can turn on a second room while the other is dark..... a "flip" relay as we used to call it.

So an analog relay box, a quality indoor/outdoor digital timer and a high heat power shut off at the main..... can't think of a safer way to grow other than in my greenhouse under the sunshine hehe

And these analog control boxes are easy to build and very affordable

Wow, that is a massive canine, Tyco. I would imagine that outdoorsmen in Canada are legally permitted to carry a sidearm when out in the wilderness. I would feel a lot safer if I had the ordnance on hand to dull that predatory curiosity coyotes sometimes display by letting fly with warning a shot or two.My grow room is outside.

Been there. Now I use mechanics gloves and just grab the branch firmly, pull quickly sliding the branch through my hands. All the buds come off in one shot. Way easier, much faster, and no more cuts. I can do a whole plant in under a minute. 2 minutes for monsters.

Speed is important to me. I had a coyote pack surround me at night last year and all I had was a tiny pair of scissors on me. I high tailed it the fuck out of there and went back the next morning to finish up. Then I was worried about getting shot because hunters were shooting up a storm. I was waiting for the zing of a bullet to whiz by me. They're big and bold up here. Here's one that was shot close to my grow by a farmer about a month later. Must be a wolf hybrid.

CharlesU Farley

Well-known member

Glad this thread got bumped. Don't have time to go all through it right now, but I've got a brother and a nephew and both are electricians, so I've got a little bit of knowledge, just by osmosis.

And usually a little knowledge is dangerous, but not in this case.

The single _most_ important thing you can do for electrical safety and fire prevention in an inside/tent environment, is to make absolutely sure you're using "arc fault outlets" .

Not GFIC outlets, which are great and keep you from getting the shit shocked out of you. But AFIC outlets, which will keep you from a Talking Heads situation and you won't be burnin' down the house.

And usually a little knowledge is dangerous, but not in this case.

The single _most_ important thing you can do for electrical safety and fire prevention in an inside/tent environment, is to make absolutely sure you're using "arc fault outlets" .

Not GFIC outlets, which are great and keep you from getting the shit shocked out of you. But AFIC outlets, which will keep you from a Talking Heads situation and you won't be burnin' down the house.

That’s how I’m controlling my lights. It’s a very confident setupthis is why i like quality relays and self built controllers along with those gfci outlets on everything.

The control center for my grow is all controlled by relays which are controlled by sealed indoor/outdoor timers. The timers never get put under the load of ballasts they only trip relays. I get all my parts through an electrical wholesaler I know and I only source the very best components though I leave that to my electrician to decide what is "best" when I order. My control box was originally built in the early 2000's but it's all analog so it's completely rebuildable if you understand the basics of wiring receptacles. I can run up to 8 x 1000w lamp flower room with 2 remaining hot plugs for fan controllers but the timer only trips the relay for the 8 receptacles that power lights. This takes all that load away from the timer as it's only job it to send electricity to trip the relay. I haven't ran it with 8 lights in years but it has been an exceptionally reliable piece of equipment in safe power distribution in my grow rooms. If I ever scale back up to running 8000W of flowering lights per room I could run 2 full rooms on this box as the relay either turns one room on and off or it can turn on a second room while the other is dark..... a "flip" relay as we used to call it.

So an analog relay box, a quality indoor/outdoor digital timer and a high heat power shut off at the main..... can't think of a safer way to grow other than in my greenhouse under the sunshine hehe

And these analog control boxes are easy to build and very affordable