-

ICMag with help from Phlizon, Landrace Warden and The Vault is running a NEW contest for Christmas! You can check it here. Prizes are: full spectrum led light, seeds & forum premium access. Come join in!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY - Build a Carbon Scrubber For Dummies!

- Thread starter DurbanPoison

- Start date

touringfunkband

Active member

Has anyone found a online source for reasonable priced granulated carbon?

Is it correct to assume you would need a separate fan for exhaust, while the scrubber being built is intended mostly for filtering rather than as a filter/exhaust combo?

Danger Will Robinson! No, no, no, no, no! All exhaust MUST run through the scrubber. Air will follow the path of least resistance. Give it another way out, allow it to bypass the filter and you'll pump the smell all over the neighborhood.

Place the scrubber at the end of run. Which end is up to you. It can be the front end or the back end but, the scrubber MUST be the only way air has to escape.

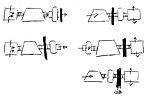

The doodles below were for someone with an aircooled hood. Such a hood is not required and should be ignored for this lesson. Key: square=scrubber, flat oval=fan, heavy black line=cab wall, trapezoid=hood. Note in EVERY instance, the scrubber is either the very first or the very last in line.

A separate fan can be used for an AC hood but that requires a dedicated duct that uses NO cab air and is another lesson for another day.

Carbon sells on Ebay for around $2lb. Fish stores and Walmart charge $5-$10lb

^ I am also looking for a cheap source of activated carbon/charcoal. I went to my local pet store and they are charging 15.99 for 22 oz!! the largest size they have... If anything I will buy that 8 lbs on ebay for $30 or so. But hoping I can find another source (checking Amazon next)Has anyone found a online source for reasonable priced granulated carbon?

Also ...

Good advice but should be mentioned its not totally true:Place the scrubber at the end of run. Which end is up to you. It can be the front end or the back end but, the scrubber MUST be the only way air has to escape.

You can indeed have this filter in-line by building a container for it. l have a wooden box completely surrounding my filter .. the ducting goes from FAN > air cooled hood > short run out of room > carbon scrubber > inside sealed wooden box > another short run to vent on side of house.

This way I save space inside the grow room but still pass every single bit of exhausted air through the filter. My box is sealed just by smooth wood against smooth wood, held with screws (for easy access to filter for maintenance). So long as connect your scrubber's intake directly to the ducting coming out of your room .. there is no worry about those leaks since all air in that box is already filtered. You just want to retain the majority of it inside the box and have one more duct connector on the box to let the air back into more duct to continue on.

Just another perspective .. thank you OP for this thread, mine came out GREAT! (I made it vastly oversized as future proofing ... and also to cut down the noise of rushing air through it should I need to use it raw without a box around it. I feel the slower the air moves through the carbon due to more surface area available in a larger filter ... the better chance it has to soak up the smellys , and the longer the carbon will last before it needs replacement. I do not feel there is such a thing as "too large" so long as you do not have ANY leaks in the system before the filter. The air MUST pass through carbon in order to get out ... sooooo too large = impossible, in my opinion.

BobbySparkle

New member

This awsome filter was paired with a diy lasko blower, the 45.00 unit available at Walmart, at the exaust end. 6" inner diameter 8" outer, with 15" surface area. Three 22 oz cartons of activated carbon from pet store to fill this badboy. Just thought to add this info.

dj digigrow

Active member

So i want to make one of these but im getting a 8" fan. so i think 750cfm. so I was gonna make a 10"dia. with a 8" core but it seems like over kill, also i have a feeling im gonna have a hard time finding 8" and 10" parts.. plus i was gonna make it 32" long which is the size i seen at the dro store for almost $400..lol

I guess i can try hvac supply spots...

I guess i can try hvac supply spots...

For a filter that size, it would probably be cheaper to buy factory made. <$200 all over the web.

dj digigrow

Active member

Thanks.. just found a 8" fan(745CFM) w/ scrubber for $260 w/ free shippin'on ebay, Ill just have to take it apart somehow later on to refill the carbon...

how do you make a carbon filter the right size for your fan? im getting a variable speed blower (300 cfm max) and also have this http://www.coolermaster.com/product.php?product_id=99 im planning on using the aero 7 to cool a 150w hps and the blower for a 2'x2'x4' space i just dont know how to make a filter for the fans (both sizes).

I'm wondering how well this formula scales to smaller PC axial fans, I have a few WFB1212HE's that I'm planning on using in what will be my new cab. The fan dimensions are 120mmx120mmx38mm and the are rated at 107.7CFM/6.3mmH20.

My cab will be 2'x2'x3' with a 250w HPS/MH, so I was planning on using a single exhaust fan with a 4"x8" intake. I was thinking of making my own 5"x5" square duct and turning that into a filter. Looking at this thread has gotten me concerned about how long I need to make this filter. Originally I was just going to make a simple scrubber with a 5"x5"x5" box though now I doubt its effectiveness.

My cab will be 2'x2'x3' with a 250w HPS/MH, so I was planning on using a single exhaust fan with a 4"x8" intake. I was thinking of making my own 5"x5" square duct and turning that into a filter. Looking at this thread has gotten me concerned about how long I need to make this filter. Originally I was just going to make a simple scrubber with a 5"x5"x5" box though now I doubt its effectiveness.

T

trem0lo

This is a great thread. For my micro grow, I made a version of this filter using two standard mesh pencil cup holders. The smaller one (inner core) is about 80mm across. I attached 80mm ducting (available at pc modding sites) to the top. For the outer core, I got a "jumbo" holder which happens to be about 120mm across. Each core I lined with pantyhose ziptied into place. The smaller core sits in the larger, but make sure you measure to get it perfectly centered. Fill in the carbon, hook up the fan, seal any gaps and you're done. Of course if you need to pack it down (for a horizontal installation) you could stuff some poly fill in there and use a fan reducer to hold it down.

This design gives you a carbon bed thickness of approximately .8" which should suffice for small boxes. I use a Noctua NF-F12 and it's nearly silent with good static pressure for an axial fan. 2.5mm/h20 at 50 cfm.

This design gives you a carbon bed thickness of approximately .8" which should suffice for small boxes. I use a Noctua NF-F12 and it's nearly silent with good static pressure for an axial fan. 2.5mm/h20 at 50 cfm.

eurasian_farmer

Member

Awesome!!

Thanks OP!!

Thanks OP!!

Luminous Melody

Member

Good Info!

Hello all...I ran across this thread and had a issues since I am not using a standard 8", 6" or 4" fan....I have a massive 19 1/2" Diameter fan ( I got for Free) and am looking to build a can filter such as this...Now the formula given at the beginning of this thread does not include such a large fan...My fan moves 2,450 CFM...Well the formula did me absolutely no good really so I had to find another way....According to what I have found for HVAC systems you take the CFM of your fan and divide that by 2 and this gives you the square inches needed for your filter. Well my 2,450 CFM cut in half gives me a surface area of 1,225 square inches. Now the inner core needs to be this size not the outer cores surface area. So according to my calculations and figures and extensive online research, I need a core diameter of 20" to slide over my fan, and this needs to be 24" in length to give me a surface area of 1,507.96 square inches. Thus being slightly larger than I need it to be but that will be fine...

Here is how I calculated the INNER CORE surface area...

2xPI(3.14)xRxH

Pi is equal to 3.14

I have a radius of 10"

And I started with a Height of 12" to see what my surface area was...was just a guess...

so 2x3.14x10x12 = 753.6 square inches

So I knew that I needed to almost double the HEIGHT

so 2x3.14x10x20 = 1256 square inches

Now 20" height would be perfect but what is the point of cutting off 4" of the hardware cloth that comes in a 24" roll? So I opted to go 24" height.

Now to figure out how much GAC (Granular Activated Charcoal) you will need...you need to find the volume of 2 cylinders and subtract them from each other...

Now my Inner Core has a radius of 10" with a height of 24"...

Formula to find the volume of a cylinder is PIxR2xh

R2 is radius Squared

So 3.14x10squaredX24 = 4.36 cu. ft.

My outer Core has a radius of 11" and is 24" in height

So 3.14x11squaredx24 = 5.28 cu. ft

5.28 - 4.36 = 0.92 cubic feet of GAC needed to fill this space.

There is a free online calculator to help you find this info quickly...

www.aqua-calc.com/calculate/volume-cyclinder

this calculator has a menu that allows you to chose imperial or metric measurement units.

Now as far as the supplies needed I had some simple 22 gauge steel sheeting (http://www.lowes.com/pd_241572-3767...product_qty_sales_dollar|1&facetInfo=3.0|24.0) bent into a circle and welded. 2 INNER CORE rings and 2 OUTER CORE rings. I used 1/4" welded wire mesh (http://www.lowes.com/pd_492388-1641...t=welded+mesh&page=1&facetInfo=Hardware cloth) that was welded to the rings giving me 2 mesh cylinders that I than covered with metal window screen(http://www.lowes.com/pd_15146-15369...ow+screen&page=1&facetInfo=7.0|Aluminum)(this was sewn on with fishing line). I then had a 22 gauge steel plate (http://www.lowes.com/pd_168747-3767..._qty_sales_dollar|1&page=1&facetInfo=2.0|24.0) welded to the inner core and the outer core to provide me with and end cap. I then had 4 L brackets (Local Hardware Store) welded to the outer core to bolt to the wall over my vent fan. I then used cotton batting (Wally World) to fill the small void at the end cap and then another piece for the other end so I can easily remove it for a refilling. I used 1 cu. ft. of GAC {$68.50 shipped (www.aquascience.net)} I also used some ratchet style "Hood" Hangers (Local Hydro Store) attached to the ceiling to help hold the weight of this bad boy....almost 40#'s!!!! works like a damn dream! and wasnt very difficult to build and is incredibly rigid and will last me for a very long time...I also have a grow area that is 24' x 40' so I needed a very large exhaust fan....

Here is how I calculated the INNER CORE surface area...

2xPI(3.14)xRxH

Pi is equal to 3.14

I have a radius of 10"

And I started with a Height of 12" to see what my surface area was...was just a guess...

so 2x3.14x10x12 = 753.6 square inches

So I knew that I needed to almost double the HEIGHT

so 2x3.14x10x20 = 1256 square inches

Now 20" height would be perfect but what is the point of cutting off 4" of the hardware cloth that comes in a 24" roll? So I opted to go 24" height.

Now to figure out how much GAC (Granular Activated Charcoal) you will need...you need to find the volume of 2 cylinders and subtract them from each other...

Now my Inner Core has a radius of 10" with a height of 24"...

Formula to find the volume of a cylinder is PIxR2xh

R2 is radius Squared

So 3.14x10squaredX24 = 4.36 cu. ft.

My outer Core has a radius of 11" and is 24" in height

So 3.14x11squaredx24 = 5.28 cu. ft

5.28 - 4.36 = 0.92 cubic feet of GAC needed to fill this space.

There is a free online calculator to help you find this info quickly...

www.aqua-calc.com/calculate/volume-cyclinder

this calculator has a menu that allows you to chose imperial or metric measurement units.

Now as far as the supplies needed I had some simple 22 gauge steel sheeting (http://www.lowes.com/pd_241572-3767...product_qty_sales_dollar|1&facetInfo=3.0|24.0) bent into a circle and welded. 2 INNER CORE rings and 2 OUTER CORE rings. I used 1/4" welded wire mesh (http://www.lowes.com/pd_492388-1641...t=welded+mesh&page=1&facetInfo=Hardware cloth) that was welded to the rings giving me 2 mesh cylinders that I than covered with metal window screen(http://www.lowes.com/pd_15146-15369...ow+screen&page=1&facetInfo=7.0|Aluminum)(this was sewn on with fishing line). I then had a 22 gauge steel plate (http://www.lowes.com/pd_168747-3767..._qty_sales_dollar|1&page=1&facetInfo=2.0|24.0) welded to the inner core and the outer core to provide me with and end cap. I then had 4 L brackets (Local Hardware Store) welded to the outer core to bolt to the wall over my vent fan. I then used cotton batting (Wally World) to fill the small void at the end cap and then another piece for the other end so I can easily remove it for a refilling. I used 1 cu. ft. of GAC {$68.50 shipped (www.aquascience.net)} I also used some ratchet style "Hood" Hangers (Local Hydro Store) attached to the ceiling to help hold the weight of this bad boy....almost 40#'s!!!! works like a damn dream! and wasnt very difficult to build and is incredibly rigid and will last me for a very long time...I also have a grow area that is 24' x 40' so I needed a very large exhaust fan....

22 Gauge Sheet metal link (http://www.lowes.com/pd_241572-3767...product_qty_sales_dollar|1&facetInfo=3.0|24.0)

canna34209

New member

awesome stuff!