Guys im back to share a recirculating dwc tutorial,Hope this helps some of you out there.Now let me hit the bong and get started

Guys im back to share a recirculating dwc tutorial,Hope this helps some of you out there.Now let me hit the bong and get started

Introduction

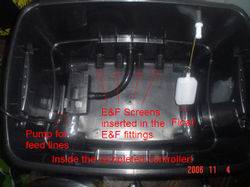

Some of you may or may not be familiar with Recirculating Dwc,However it is just a multiple bucket version of Dwc "DEEP WATER CULTURE" that is all connected to a single controller,Where nutrients is pumped from a pump to the top of each bucket,And returns through the bottom of each bucket back to the controller,Basically continuously mixing the nutrient solution making it stable through-out the whole system.The controller will have a float valve installed where it is connected to a reservoir which will auto top/feed the system.Each bucket will have an airline and airstone/air difffuser.Or the controller will have a powerhead installed.This is how the water/nutrient solution will get its Do "DISSOLVED OXYGEN".

Pros

The Bennifits to this system are!You can cool the whole system using a single water chiller.The system will auto top off and mix nutrient solution 24/7 keeping ph and ppm stable from bucket to bucket.And the growth and vigor is explosive when optimized.

Cons

Well the drawbacks,#1 is that this system uses lots of water.#2 is that its recirculating,So if one plants root system gets effected it can/will spread through out the system.Though on this version i put shut off valve on each row to insure if problem accurs i can isolate it to one single row.Its also possible for the roots to clog the return line causing an overflow however in this version thats very unlikely.

Adding up the parts list

Ok this is a tutorial on a 12 bucket system,The parts list will vary depending on how many buckets.Each bucket will require 1x 1/4" straight barb,1x 1/4" barbed elbow,1x 3/4" ebb n flow fitting,1x 2' air diffuser or airstone.You will need some 3/4" tees and elbows,The ammount will vary depending on number of buckets and rows.For example im running 4 rows of 3 buckets,I will need 8 t's and 4 elbows for connecting the buckets in each row.Now for the controller you will need 1x ebb n flow fitting for each row you will be running,For example im doing 4 rows of 3 buckets,So i will need to be able to connect 4 return lines to the controller.The feed line will only need 1x 1/2" ebb n flow fitting the rest will be split through t's and tubing.I suggest always buy extra elbows and t's as you may need them either way remember this is a part list for a 12 bucket system.Also i suggest buying black buckets ordering off the net as i bought white buckets locally and spray painted them pain in the arse imo.So i reccomend purchasing black 5 gallon buckets.

Parts list

12x 5 gallon buckets

12x lids with 6" nets built in

12x 2' air diffusers

1x 18 gallon rubbermaid tub

1x 45 gallon reservoir

16x 3/4" elbows

16x 3/4" tee's

16x 3/4" (tub outlets) ebb n flow fittings

22x Ebb n Flow Screens

4x 3/4" shut off valves

2x 1/2" ebb n flow fittings

24x 1/4" straight barbs

70 7/8" hose clamps

12x 1/4" barbed elbows

4x 1/2" shut off valves

4x 1/2" end caps

100' 3/4" ID tubing

100' 1/4" ID tubing

50' 1/2" ID tubing

1x Float valve

1x eco 264 gph water pumps

2x eco 8 air pumps

Tools list

1x Drill

1x 3/16" bit

1x 3/8" bit

1x 1&1/4" hole saw bit with starter bit

1x Needle nose plyers

1x sharp knife

1x heavy duty scissors

Now i will post links to some places you can order all the supplies from!

You can get the 5 gallon buckets black cheap here!

http://www.usplastic.com/catalog/pr...SPlastic&category_name=20327&product_id=26588

Now heres a couple links to places that carry all the rest of the equipment,Exept the 18 gallon rubber maids which can be ordered through home depot or lowes either one.

http://www.texashydroponics.com/shop/home.php

http://www.wormsway.com

Time for a smoke break will finish this tutorial promtly!

Last edited:

Gotta get my seat early for this one

Gotta get my seat early for this one