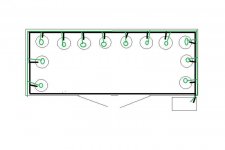

I have always done a 30 sec/quart pulse feed through drip rings every 90 mins.

I have never screened my Turface, only rinsed it very well. Some of my buckets are visible dry looking every place on top except where the ring is.

Should I be concerned?

I do poke my finger through the top layer about an 1" and it is moist.

Should I up my rate to 60 mins?

Hey chap - forgot to mention you should both screen and rinse properly. Not screening is a mistake, your AFP is way way too low for optimal root growth. In ppk you grow roots, not leaves and stems....

Sorry, it's Saturday question night

Sorry, it's Saturday question night

I was thinking more so on using less for this set up.

I was thinking more so on using less for this set up.