Hi!

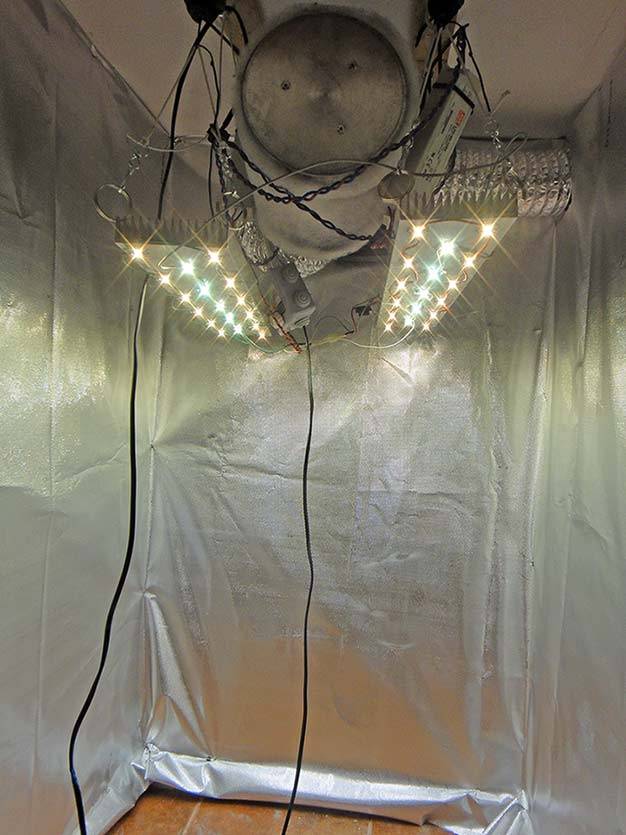

The chamber

The "chamber" is an understairs space, measuring 60x70cm (23"x28") area, 1.20m (4') height. Surface is 0.43 sq meter or 4,7 sq feet and volume is 0,5 cubic meter, or 18,7 cubic feet.

One of the problems you face when trying to prop everthing up in the chamber "ceiling" is the unsderstairs concrete is a real PITA to drill, so I simply glued timber pieces to it, then screw all the hooks I need easily to it by hand.

I built a 3 piece timber "frame", then hung the "door" on the upper frame. The door is a wood sheet with the reflective covering stapled to it.

I stapled the reflective covering to the walls, fixed an AC inline extractor (120CFM) to the back wall. It vents through a wall air conduit, and pulls air through a Mountain Air Carbon Scrubber rated for 150CFM.

I built a dimmer to regulate its speed, not only for noise, but to dial humidity. It's always on.

A couple PC fans circulate air, one below the screens, one above, that will eventually have a twin soon.

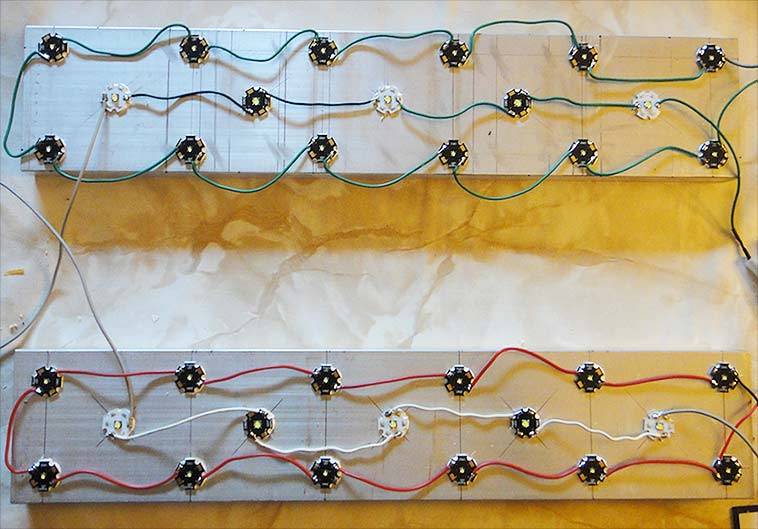

The Home Made LED (HML)

Last week the items for my Home Made LED unit arrived and I built it.

The items:

100x25cm Finned Heatsink I cut in two 50 cm long pieces.

Drivers: 2 Mean Well LPC-60-1050 driving a string of 12 XP-G WW each, and one LPC-60-1750 driving a 10 XM-L string (5 XM-L in each heatsink).

LEDs (Cree already in MCPCBs):

24 Warm White XP-G (5W)

6 Neutral White XM-L (10W)

4 Cool White XM-L (10W)

Artic alumina thermal epoxy to glue the LEDs MCPCBs to the heatsinks.

This gives 220Watts raw, will be run @ ~150-160Watts.

The plan:

Each heatsink has 12 WW XP-Gs, 3 NW XM-L and 2 CW XM-L (black circle: NW, red circle WW, blue circle CW):

I tested all the LEDs, tinned the MCPCBs, mark their placement on the heatsinks, placed them w/o gluing yet to check the MCPCB "orientation" to ease wiring, then glued them, finished the wiring, tested for shorts with a multimeter, checked visually three times that the wiring was right, then hooked each string to its driver and lit them.

I put an inline fuse in the positive rail with each of the strings: 1,5A for the XP-G's and 3A for the XM-Ls.

I checked AC amperage, 0.25A the LPC-60-1050 (AC voltage read 232V), or 58W. The LPC-60-1750 0.4A. That's 90Watts, had me puzzled as expected the 1750 to be much more efficient.

Mad brightness, had to be careful not to ever look directly to the lit chips.

The heatsinks get hot, but you can touch them and hold the finger there.

I have put them 15" (40cm) above the canopy. Still in 18/6, I intend to flip to 12/12 by mid week, still have to repot one clone and prop its screen.

I vegged 2 seedlings: Somango on 16th Sept and Amnesia Haze one week later with a two 55W PLL fixture I built myself. A mate gave me a couple Atomic Haze clones, which have been vegging for a week under that same PLL.

Lots of changes at once, something not advisable as if anything goes wrong there will be lots of variables to check, but... had no other chance:

Swapped the PLL for the HML

Repotted all the plants, but one clone, as ran out of coco!

Fitted the modular screens

Put the Tropf Blumat cones and its tubing

Set up the reservoir

I repotted to 11L pots and fitted the modular screens.

The somango had to be severely bent/supercropped to fit under the screen.

I gave them a dose of rhizotonic + B52 (PH 5.7, EC 0.9), until all the pots were well wet, then put the blumats that had been sitting in a water jar for a couple days on saturday, then fitted the tubing and setup the reservoir on Sunday. I adjusted each blumat so that it dripped 1 drop per second, then closed a couple markings.

The reservoir has an small aquarium pump inside, that fires 15 minutes on, 15 minutes off.

I filled the reservoir with tap water (0.4EC), adding Canna's coco A+B solution for EC 1.8, PH'ed to 5,6 and added Drip clean.

The chamber

The "chamber" is an understairs space, measuring 60x70cm (23"x28") area, 1.20m (4') height. Surface is 0.43 sq meter or 4,7 sq feet and volume is 0,5 cubic meter, or 18,7 cubic feet.

One of the problems you face when trying to prop everthing up in the chamber "ceiling" is the unsderstairs concrete is a real PITA to drill, so I simply glued timber pieces to it, then screw all the hooks I need easily to it by hand.

I built a 3 piece timber "frame", then hung the "door" on the upper frame. The door is a wood sheet with the reflective covering stapled to it.

I stapled the reflective covering to the walls, fixed an AC inline extractor (120CFM) to the back wall. It vents through a wall air conduit, and pulls air through a Mountain Air Carbon Scrubber rated for 150CFM.

I built a dimmer to regulate its speed, not only for noise, but to dial humidity. It's always on.

A couple PC fans circulate air, one below the screens, one above, that will eventually have a twin soon.

The Home Made LED (HML)

Last week the items for my Home Made LED unit arrived and I built it.

The items:

100x25cm Finned Heatsink I cut in two 50 cm long pieces.

Drivers: 2 Mean Well LPC-60-1050 driving a string of 12 XP-G WW each, and one LPC-60-1750 driving a 10 XM-L string (5 XM-L in each heatsink).

LEDs (Cree already in MCPCBs):

24 Warm White XP-G (5W)

6 Neutral White XM-L (10W)

4 Cool White XM-L (10W)

Artic alumina thermal epoxy to glue the LEDs MCPCBs to the heatsinks.

This gives 220Watts raw, will be run @ ~150-160Watts.

The plan:

Each heatsink has 12 WW XP-Gs, 3 NW XM-L and 2 CW XM-L (black circle: NW, red circle WW, blue circle CW):

I tested all the LEDs, tinned the MCPCBs, mark their placement on the heatsinks, placed them w/o gluing yet to check the MCPCB "orientation" to ease wiring, then glued them, finished the wiring, tested for shorts with a multimeter, checked visually three times that the wiring was right, then hooked each string to its driver and lit them.

I put an inline fuse in the positive rail with each of the strings: 1,5A for the XP-G's and 3A for the XM-Ls.

I checked AC amperage, 0.25A the LPC-60-1050 (AC voltage read 232V), or 58W. The LPC-60-1750 0.4A. That's 90Watts, had me puzzled as expected the 1750 to be much more efficient.

Mad brightness, had to be careful not to ever look directly to the lit chips.

The heatsinks get hot, but you can touch them and hold the finger there.

I have put them 15" (40cm) above the canopy. Still in 18/6, I intend to flip to 12/12 by mid week, still have to repot one clone and prop its screen.

I vegged 2 seedlings: Somango on 16th Sept and Amnesia Haze one week later with a two 55W PLL fixture I built myself. A mate gave me a couple Atomic Haze clones, which have been vegging for a week under that same PLL.

Lots of changes at once, something not advisable as if anything goes wrong there will be lots of variables to check, but... had no other chance:

Swapped the PLL for the HML

Repotted all the plants, but one clone, as ran out of coco!

Fitted the modular screens

Put the Tropf Blumat cones and its tubing

Set up the reservoir

I repotted to 11L pots and fitted the modular screens.

The somango had to be severely bent/supercropped to fit under the screen.

I gave them a dose of rhizotonic + B52 (PH 5.7, EC 0.9), until all the pots were well wet, then put the blumats that had been sitting in a water jar for a couple days on saturday, then fitted the tubing and setup the reservoir on Sunday. I adjusted each blumat so that it dripped 1 drop per second, then closed a couple markings.

The reservoir has an small aquarium pump inside, that fires 15 minutes on, 15 minutes off.

I filled the reservoir with tap water (0.4EC), adding Canna's coco A+B solution for EC 1.8, PH'ed to 5,6 and added Drip clean.

A little late , but I am 100% subbed !

A little late , but I am 100% subbed !

.

.

(even so I intend to do some breeding experiments this winter, but in a separate place of course).

(even so I intend to do some breeding experiments this winter, but in a separate place of course).