madpenguin

Member

So, I have 250' of 12gauge-3 Romex (plenty) wire. The plan is to wire them to 2 x 20amp circuits.

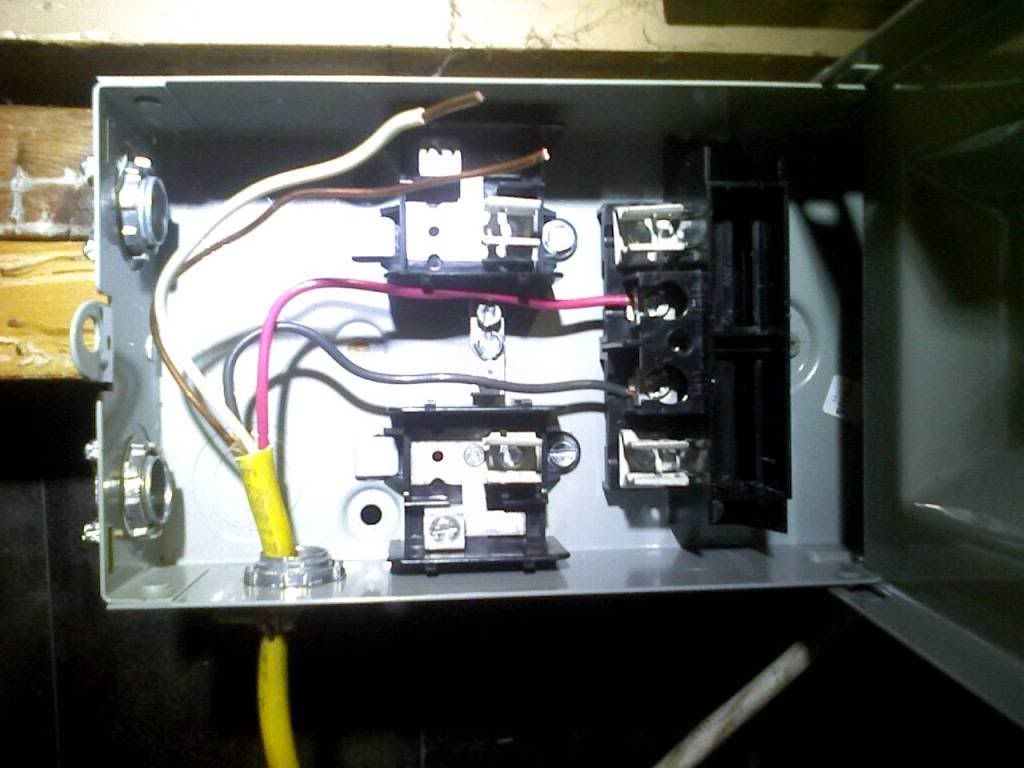

If your going to use 12/3 wire for 2 separate 20A runs then you have to use a double pole 20A breaker. Red wire to one breaker screw and the black wire to the other.

Or, you can use 2 individual single pole 20A breakers but you would have to use 2 separate runs of 12/3 and abandon either the red or black wire in both runs (treat it like it's a 12/2 run).

O.k... I kinda wish people wouldn't run MWBC's unless they are familiar with electricity. If your going to add another 4 square into the mix (4"x4" junction box), for a total of 3, then make sure 3 duplex receptacles are fed by the red wire and the other 3 duplex receptacles are fed by the black wire.From there, they will goto individual 2 x 4" x 4" metal boxes with 4 x GFCI outlets (in total). (such as one 12 guage wire to one 4" x 4" box... each having 4 places to plug in... now that I'm writing this, I will probably need another 4" x 4" box pig tailed since I need atleast 11 plugs.

Physically mark these receptacles with a permanent red and black marker so you know which is fed by which. Then lay out all your equipment and write down what the amperage/wattage draw is for each device. Now try to even both the red and black wires out so they are drawing approximately the same amount of power.

Wirenut ALL neutrals with pigtails. Don't daisy chain your neutral wire from receptacle to receptacle. Mechanically twist all neutral pigtails to the main neutral with linemans pliers so you have a solid twist of the wires BEFORE you wirenut it....

Bud-Boy, that applies to you as well!!!