In the US benzene is the chemical name for a highly carcinogenic compound. "Because benzene is a human carcinogen, most non-industrial applications have been limited."

https://en.wikipedia.org/wiki/Benzene

And petroleum benzine is a relatively unknown, and loosely defined term for a petroleum faction.

https://en.wikipedia.org/wiki/Petroleum_ether

Petroleum ether

From Wikipedia, the free encyclopedia

"Benzine" redirects here. It is not to be confused with Benzene.

Petroleum ether is the petroleum fraction consisting of aliphatic hydrocarbons and boiling in the range 35‒60 °C; commonly used as a laboratory solvent. The term ether is used only figuratively, signifying extreme lightness and volatility."

"The very lightest, most volatile liquid hydrocarbon solvents that can be bought from laboratory chemical suppliers may also be offered under the name petroleum ether."

"Petroleum ether bears normally a descriptive suffix giving the boiling range. Thus, from the leading international laboratory chemical suppliers it is possible to buy various petroleum ethers with boiling ranges such as 30-50 °C, 40-60 °C, 50-70 °C, 60-80 °C, etc. In the United States, laboratory grade aliphatic hydrocarbon solvents with boiling ranges as high as 100-140 °C may be called petroleum ether, rather than petroleum spirit."

"Ligroin is assigned the CAS Registry Number 8032-32-4, which is also applied to many other products, particularly the lower boiling ones, called petroleum spirit, petroleum ether, and petroleum benzine. "Naphtha" has the CAS Registry Number 8030-30-6, which also covers petroleum benzine and petroleum ether: that is, the lower boiling point non-aromatic hydrocarbon solvents.

DIN 51630 provides for petroleum spirit (also called spezialbenzine or petrolether) which is described as "a special boiling-point spirit commonly used in laboratory applications, having high volatility and low aromatics content." Its initial boiling point is above 25 °C, its final boiling point up to 80 °C."

So what is the "benzine" Rick Simpson is referring to in this video? (or see the attached screenshot)

https://www.youtube.com/watch?v=5ZK-1hQ9QbQ

He could be referring to light petroleum ether, but from the Wiki quotes above you can see this could be anything from the 35-60C faction, which is just pentane and hexane to broader factions up to naphtha.

Benzene (the carcinogenic compound) has a boiling point of 80C, so a petroleum benzine (petroleum ether) faction below 80C (35-60C) doesn't contain benzene.

White gas, Coleman Fuel, naphtha, and lighter fluid can't say they're near 100% anything on their MSDS's. In spite of what Rick says, they are crude solvents in that they contain benzene, and even minute residual traces (> 2 ppm) of benzene have been declared unacceptable by the FDA.

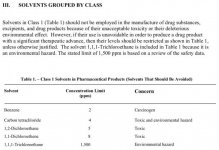

FDA USP <467> Residual Solvent classification lists,

https://www.usp.org/sites/default/files/usp_pdf/EN/USPNF/generalChapter467Current.pdf

Petroleum ether (35-60C)

https://www.rightpricechemicals.com/buy-petroleum-ether-35-60-ligroin-online.html

Pentane (36C)

https://www.rightpricechemicals.com/buy-n-pentane-99-online.html

Hexane (69C)

https://www.rightpricechemicals.com/buy-hexanes-online.html

Benzene (80C) highly carcinogenic!!!

https://www.rightpricechemicals.com/buy-benzene-reagent-acs.html

Otherwise, right on Rick!!!

I just discovered Rick Simpson's take on this from several years ago.

Rick Simpson

July 7, 2013

Has Arno Hazekamp gone nuts or what? Has he ever produced an extremely potent and sedative 95-98% THC oil with olive oil? Really?

Show me the lab results if you have them, Arno. If you don't, don't give people such stupid and irresponsible advice. You don't know the difference between light and heavy naphtha, you use Coleman fuel which we don't recommend, and you pretend to be an expert in extraction methods and you draw conclusions? Based on what? This is really ridiculous and this piece of false information is going to kill patients worldwide and Arno Hazekamp will be directly responsible for that.

Congratulations, Arno. You don't have a clue about what you caused by these outrageous and stupid lies. You are just another "scientist" who follows from wrong assumptions, that's all there is to it. You should have asked what to do, you would not make a fool out of yourself.

Your advice is wrong. Coleman fuel is not what we recommend and if you took the time to read our instructions, you would see that piece of information right there. We recommend pure light naphtha. That means pure, no additives. And you made a scientific study about a solvent we don't recommend or use because it has additives in it.

Why exactly did you do that? To prove that Coleman fuel is not a solvent we recommend? Is this why you went to a university? You can't read the instructions and follow them? Is it really so difficult for you? You are a scientist and you don't know that there are additives in Coleman fuel?

How many terminal patients have you cured to be able to draw conclusions about "the best way" to make Rick Simpson Oil, Arno? You have never seen the RSO, you don't know what it is and you make studies about it. If you knew what the RSO is, you would never write such nonsense like you did. Bye. JB

Exacting About Extracting, Backes Backs Olive Oil

Michael Backes kicked off an informative discussion about extraction methods with a recent post that quoted in full an FAQ piece by Arno Hazekamp. Here’s why Backes, who is director of research & development at the Los Angeles Patients & Caregivers Group, backs olive oil.

“I speak with hundreds of persons with cancer about cannabis. Nearly all of them ask me about using cannabis oil to cure their cancer. Here’s what I tell them…

The majority of oncologists in United States recommend cannabis to their patients, whether they live in medical cannabis states or not. That’s reality. They typically recommend it for symptomatic relief of the side effects of cancer treatment. Ask any oncologist. Oncologists have been recommending cannabis to people with cancer since the ’80s. It’s not some suppressed medicine.

Cancer has been around for as long as we’ve been around. Cannabis has been around as a medicine for thousands of years. Cannabis was not considered a cancer treatment, back in the day. It may be preventative of some cancers, then and now. It might also encourage a few cancers, too. Cannabis may provide promising treatments for a variety of tumors. But… it may also encourage certain types of cancer and it would be nice to know which ones it kills or slows and which ones it encourages. Medical science doesn’t know, so caution is definitely advised.

Cannabis oil for topical treatment of some forms of skin cancer looks like a very promising treatment and appears to have been effective for many people with certain forms of skin cancer. Will it work for all skin cancers? No, it won’t. Skin cancers come in too many forms and not all will respond to cannabinoid therapy.

High dose oral cannabinoid therapy with cannabis oil is going to down regulate parts of the endocannabinoid system resulting in reduced cannabinoid receptor density. There is no one that can currently tell us what reducing that receptor density does.

It may be that high dose cannabinoid therapy with cannabis oil retards the proliferation of some types of cancer and tumors. It may be that low dose cannabinoid therapy cures others. It may be that certain cannabinoids kill certain cancers and encourage other cancers. This isn’t a simple problem, so don’t listen to simpletons for advice when dealing with it.

Cannabis oil is an unproven treatment for cancer. It is not a cure for cancer. A cure for cancer is considered something that keeps you cancer-free for five years. There aren’t enough people that have treated their cancer with cannabis oil and are cancer-free to make the assertion that cannabis oil is a cure.

If you want to self-experiment with cannabis oil on your cancer, that is your right. It may not be your right to experiment on someone else.

The question is what is the most effective delivery method for cannabis oil therapy, oral, oromucosal, inhaled, or topical. Likely depends on the specific form of cancer and whether the cancer has spread.

Not all cannabis oil is the same. The difference depends on the cannabis variety from which it was extracted. Cannabis extractions that were sold as medicine in the 19th and early 20th centuries by big pharma were extracted from varieties of cannabis that are not widely available today. And the difference between yesterday’s cannabis and today’s cannabis is an important difference, when it comes to medicinal chemistry.

Cannabis oil that is available in most dispensaries is high-THC with no CBD whatsoever. CBD is not easy to find, but it is getting easier. CBD is not responsible for the “indica” effect (like a well-meaning person told me at a dispensary last week).

Cannabis oils made with solvents other than ethanol are difficult to purge of solvent residues. Solvent residues can be unsafe and some could potentially interfere with immune function required to fight off certain forms of cancer.

The safest way to make cannabis oil is not with Rick Simpson’s recipe. It’s with olive oil. And you won’t blow yourself up making infused olive oil and it’s cheaper than using solvents. Preferably make the oil from cannabis that has been lab screened for bacteria and molds. Never infuse raw cannabis into olive oil without pasteurizing the finished product. Anerobic pathogenic bacteria can thrive in olive oil.

Cannabis infused olive oil is highly perishable. It needs to be kept very cold and in the dark.

And lastly, I am not doctor and I don’t pretend to be one. I do believe that people have the right to treat themselves. I do not believe that people have some innate right to practice medicine on others.

Here’s a great new FAQ on cannabis oil from researcher Arno Hazekamp that was posted today, May 5, 2013 on the International Association for Cannabis as Medicine website . Definitely worth a read. My only suggestion would be to do his suggested infusion in a pressure cooker, since pressure cooking will kill any pathogen on the cannabis.

What is the best and healthiest way to produce cannabis oil?

by Dr. Arno Hazekamp

What is Cannabis oil?

Concentrated cannabis extracts, also known as Cannabis oils because of their sticky and viscous appearance, are increasingly mentioned by self-medicating patients as a cure for cancer. In general, preparation methods for Cannabis oil are relatively simple and do not require particular instruments. The purpose of the extraction, often followed by a solvent evaporation step, is to make cannabinoids and other beneficial components such as terpenes available in a highly concentrated form. Cannabis oil is usually taken orally, by ingesting a small number of drops several times a day. Please find here some information on the question whether cannabis can cure cancer.

How is Cannabis oil prepared?

Various methods have been described for the preparation of Cannabis oil. The most popular method, as described by former (skin)cancer patient Rick Simpson from Canada, suggests the use of naphtha or petroleum ether as a solvent for the extraction. Following the success of Simpson oil, a number of related recipes have sprung up, emphasizing small but significant changes to the original recipe. Examples include focusing on safer solvents such as ethanol, or preventing exposure to organic solvents altogether, by using olive oil.

What is naphtha or petroleum-ether?

In general, petroleum-ether and naphtha refer to very similar products, even though different names may be used around the world; e.g. in some countries naphtha is equivalent to diesel or kerosene fuel. Both solvents are a mixture of petroleum hydrocarbons (PHCs), often available in a wide range of qualities. All the solvent components should be considered harmful and flammable, and some of them, such as hexane and benzene, may be neurotoxic. Both naphtha and petroleum-ether are considered potential cancer hazards according to their manufacturers. Moreover, products sold as naphtha may contain added impurities (e.g. Coleman® fuel) which may have harmful properties of their own.

Are residual solvents a health risk?

Although Cannabis oils are usually concentrated by evaporating the solvents that were used for extraction, this does not completely eliminate residual solvents. As a result of sample viscosity, the more concentrated an extract becomes, the more difficult it will be to remove the residual solvent from it. In such a case, applying more heat will increase solvent evaporation, but simultaneously more beneficial components (such as cannabinoids or terpenes) may be lost as well. The use of non-toxic solvents should therefore always be advised, so that potential residues are not harmful to health.

What is the best and healthiest way to prepare Cannabis oil?

Recently, an analytical study (link to the article will follow here in a few days) was performed to compare several generally used preparation methods on the basis of cannabinoids, terpenes, and residual solvent components. Solvents tested included ethanol, naphtha, petroleum-ether, and olive oil. Based on this study, the following recommendations can be made:

As extraction solvents, ethanol and olive oil were shown to perform the best, extracting the full range of terpenes and cannabinoids present in cannabis plant material very efficiently. Additionally these solvents are safe for consumption.

Unfortunately, pure ethanol also extracts large amounts of chlorophyll from cannabis material, which will give the final extract a distinct green, and often unpleasant, taste. Removing chlorophyll by filtering the ethanol extract over activated charcoal was found to be effective, but it also removed a large proportion of cannabinoids and terpenes, and is therefore not advised. Additionally, in many countries consumption-grade ethanol is an expensive solvent, as a result of added tax on alcohol products.

Of the solvents tested, this leaves olive oil as the most optimal choice for preparation of cannabis oil for self-medication. Olive oil is cheap, not flammable or toxic, and the oil needs to be heated up only to 100°C (by placing a glass jar containing the product in boiling water for 1-2 hours) so no overheating of the oil can occur. After cooling down and filtering the oil it is immediately ready for consumption. As a trade-off, however, olive oil extract cannot be concentrated by evaporation, which means patients will need to consume a larger volume of it in order to get the same therapeutic results.

Preheating of cannabis to ‘activate’ (decarboxylate) the cannabinoids may result in loss of terpenes as a result of evaporation. If the full range of terpenes is desired in the final Cannabis oil, dried buds and leaves can be used directly for extraction, without preheating.

About the author

Dr Arno Hazekamp is a phytochemical researcher at the Department of Plant Metabolomics of Leiden University, The Netherlands. He also coordinates the R&D program at Bedrocan BV. This FAQ was posted on the invaluable IACM website, where you’ll also find a relevant paper by Luigi Romano and Hazekamp, Cannabis Oil: chemical evaluation of an upcoming cannabis-based medicine.

http://www.cannabis-med.org/data/pdf/en_2013_01_1.pdf

https://www.facebook.com/ricksimpsonofficial/posts/535157236531420

Last edited: