St. Phatty

Active member

This is one of those Fast & Furious type questions.

Plus, I watched Maloof Racing on Netflix.

They use Nitrous Oxide - for Racing AND for Dental Anaesthesia ?

Now that is one Versatile Chemical Compound ! !!

"The purpose of a nitrous oxide system is **to increase the power output of an engine** . It does this by increasing the amount of fuel that can be burned, by increasing the oxygen supply."

So, if they want more Oxygen - why not use a tank of Compressed Oxygen, and fold that into the inflow of Atmospheric Air, 80% Nitrogen 20% Oxygen 420 ppm CO2 ?

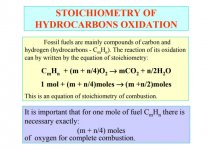

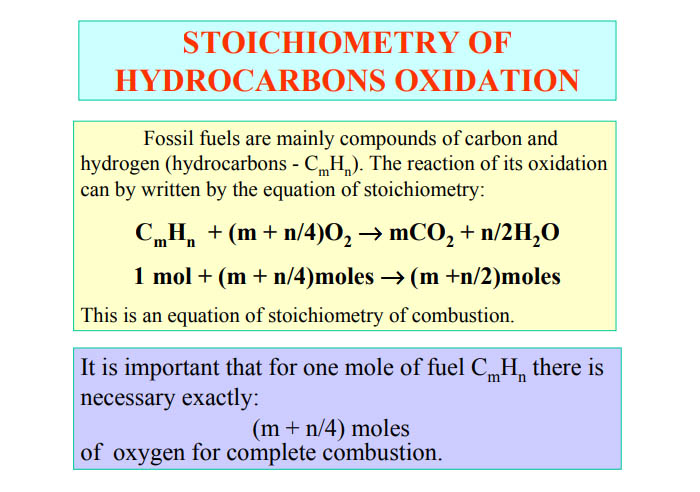

Does anyone know the formula/ Stoichiometry for burning Gasoline with Nitrous Oxide ?

Plus, I watched Maloof Racing on Netflix.

They use Nitrous Oxide - for Racing AND for Dental Anaesthesia ?

Now that is one Versatile Chemical Compound ! !!

"The purpose of a nitrous oxide system is **to increase the power output of an engine** . It does this by increasing the amount of fuel that can be burned, by increasing the oxygen supply."

So, if they want more Oxygen - why not use a tank of Compressed Oxygen, and fold that into the inflow of Atmospheric Air, 80% Nitrogen 20% Oxygen 420 ppm CO2 ?

Does anyone know the formula/ Stoichiometry for burning Gasoline with Nitrous Oxide ?