yukino_asano

Member

Hello,

finally figured out how to get the best of both worlds without having an outrageous amount of ducting

the best of both worlds being.

c02 injection during lights on and in out air during lights off.

wanted to share so hopefully will help others out in understanding how controlled enviroment agriculture aka a sealed room works

started with in and out air to control temps.

I now been using c02 with a air conditioner in my grow room and saw an excellent improvement.

Made a new floor plan and been implementing some changes.

Since I started with in and out air I left my carbon filter and exhuast fan in place. This is usefull for for exhuasting air when the lights are off.

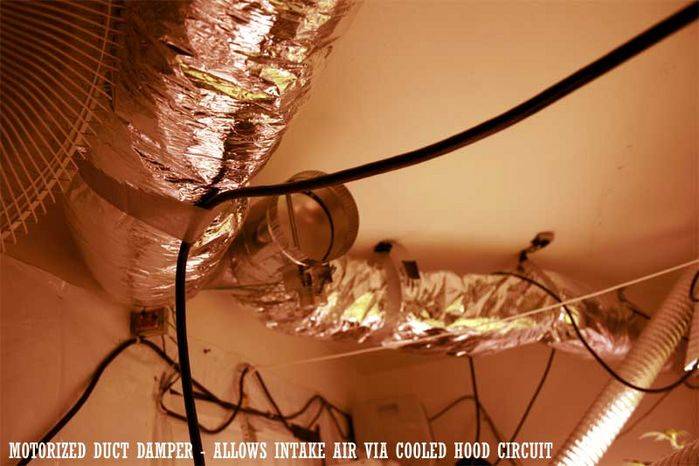

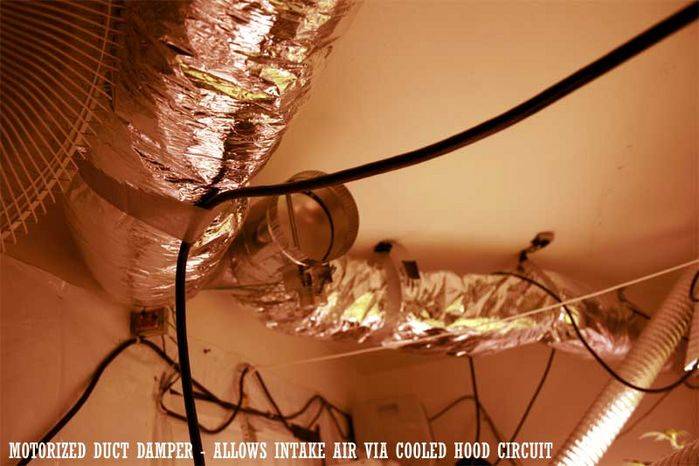

I also added a y to the ducting for my hoods, and then added a motorized duct damper. This in combination with other duct dampers with allow the air ducting circuit to also provide air flow at night time when I am not venting the hoods.

this way you get a sealed room with ac controlled temps when lights are on then when the lights are off the exhuast fan is taking air in via the hood circuit.

well here are some pics to help explain.

the floor plan to help you get a bird eye view of what is going on. (please ignore carbon filter after exiting hoods. isnt needed with well sealed hoods)

sentinel controller, it "sniffs" the amount of c02 in the room and controls the tanks

Duct damper: this prevents c02 from being wasted via the duct work, see floor plan menu for placement of duct dampers.

open closed dampers pics

Air intake

carbon scrubber and dehumidifier

Air conditioner (18,000 btu window unit set to recirculate, on 24/7)

motorized duct damper, this is on a timer. opens while lights are off.

few more pics of different views

so please share any info or questions.

looking forward to going into flower with this new setup

peace

[B]-YuKINO[/B]

finally figured out how to get the best of both worlds without having an outrageous amount of ducting

the best of both worlds being.

c02 injection during lights on and in out air during lights off.

wanted to share so hopefully will help others out in understanding how controlled enviroment agriculture aka a sealed room works

started with in and out air to control temps.

I now been using c02 with a air conditioner in my grow room and saw an excellent improvement.

Made a new floor plan and been implementing some changes.

Since I started with in and out air I left my carbon filter and exhuast fan in place. This is usefull for for exhuasting air when the lights are off.

I also added a y to the ducting for my hoods, and then added a motorized duct damper. This in combination with other duct dampers with allow the air ducting circuit to also provide air flow at night time when I am not venting the hoods.

this way you get a sealed room with ac controlled temps when lights are on then when the lights are off the exhuast fan is taking air in via the hood circuit.

well here are some pics to help explain.

the floor plan to help you get a bird eye view of what is going on. (please ignore carbon filter after exiting hoods. isnt needed with well sealed hoods)

sentinel controller, it "sniffs" the amount of c02 in the room and controls the tanks

Duct damper: this prevents c02 from being wasted via the duct work, see floor plan menu for placement of duct dampers.

open closed dampers pics

Air intake

carbon scrubber and dehumidifier

Air conditioner (18,000 btu window unit set to recirculate, on 24/7)

motorized duct damper, this is on a timer. opens while lights are off.

few more pics of different views

so please share any info or questions.

looking forward to going into flower with this new setup

peace

[B]-YuKINO[/B]

Last edited: